A kind of propylene polymer and preparation method thereof

A technology for propylene polymer and olefin polymerization, applied in the field of propylene polymer and its preparation, can solve the problems of low polypropylene regularity, easy fouling of processing equipment, low stereospecificity and polymerization activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029]The invention provides a method for preparing a propylene polymer, the method comprising: under olefin polymerization conditions, in the presence of a catalyst, propylene or propylene and ethylene and / or selected from C 4 -C 8 A mixture of α-olefins is polymerized, the catalyst contains a solid component, an alkylaluminum compound and optionally an external electron donor compound, the solid component comprising the reaction product of the following components:

[0030] (i) magnesium-containing compounds;

[0031] (ii) titanium-containing compounds; and

[0032] (iii) internal electron donors;

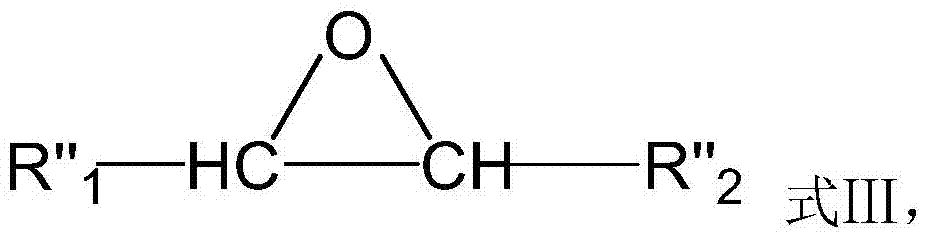

[0033] Wherein, the internal electron donor is a combination of internal electron donor compound a, internal electron donor compound b and internal electron donor compound c.

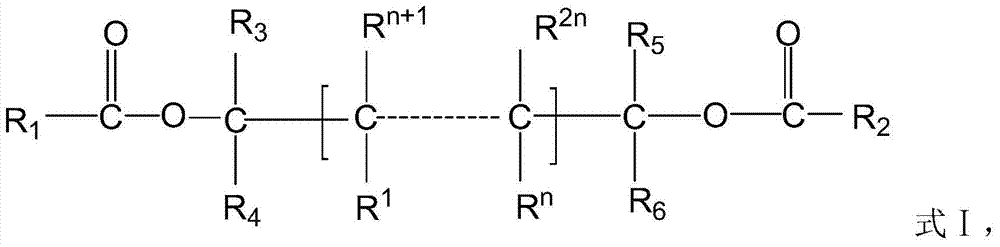

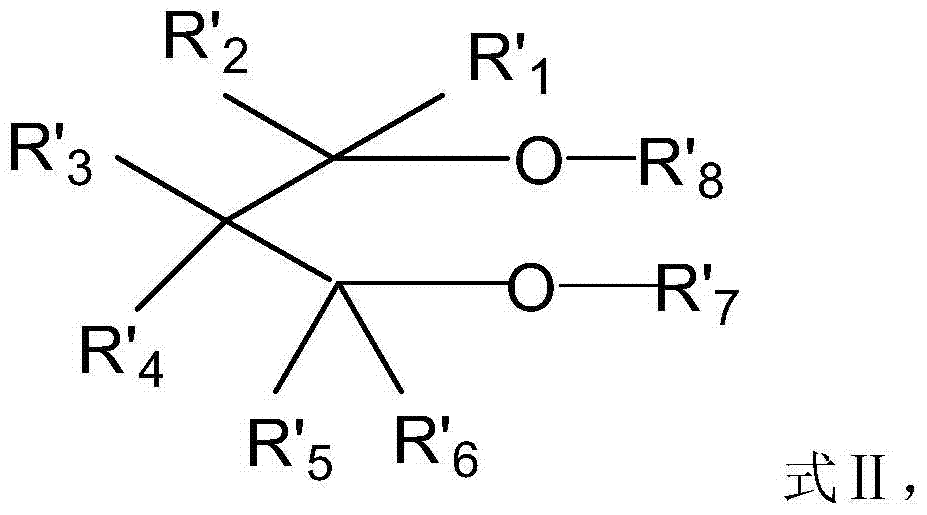

[0034] According to the present invention, the internal electron donor compound a is a glycol ester compound represented by formula I,

[0035]

[0036] In formula Ⅰ, R 1 and R 2 the same or diffe...

Embodiment 1

[0114] This example is used to illustrate the propylene polymer provided by the present invention and its preparation method.

[0115] Preparation of the catalyst solid component: In a 300mL stirred glass reaction flask fully replaced by high-purity nitrogen, add 0.912mol of titanium tetrachloride and 10mL of hexane, cool to -20°C, add 8g (0.0372mol) Spherical magnesium chloride alcoholate (MgCl 2 2.6C 2 h 5 OH, synthesized with magnesium dichloride and ethanol according to the method disclosed in CN1330086A), under stirring, slowly heat up in stages, add 2,4-pentanediol dibenzoate (internal electron donor compound a) 5mmol , 2-isopropyl-2-isoamyl-1,3-dimethoxypropane (internal electron donor compound b) 5mmol and epichlorohydrin (internal electron donor compound c) 1.5mmol, continue to heat up to 110°C, after reaching the temperature and keeping the temperature for 0.5h, remove the liquid by suction filtration, and add titanium tetrachloride to the solid phase obtained by ...

Embodiment 2

[0119] This example is used to illustrate the propylene polymer provided by the present invention and its preparation method.

[0120] Preparation of catalyst solid component: prepare olefin polymerization catalyst solid component according to the method of Example 1, and prepare polypropylene according to the method of Example 1, the difference is that in the process of propylene polymerization, cyclohexylmethyl dimethyl Oxysilane. The isotactic index and ash content of the obtained polypropylene and the test results of the polymerization activity of the catalyst are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| isotactic index | aaaaa | aaaaa |

| isotactic index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com