Circulating cooling water dialysis system

A technology of circulating cooling water and circulating water tank, applied in the field of water treatment, can solve the problems of shortened machine life, frequent water changes and sewage, equipment corrosion, etc., and achieve the effects of solid-liquid separation, clear circulating water, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

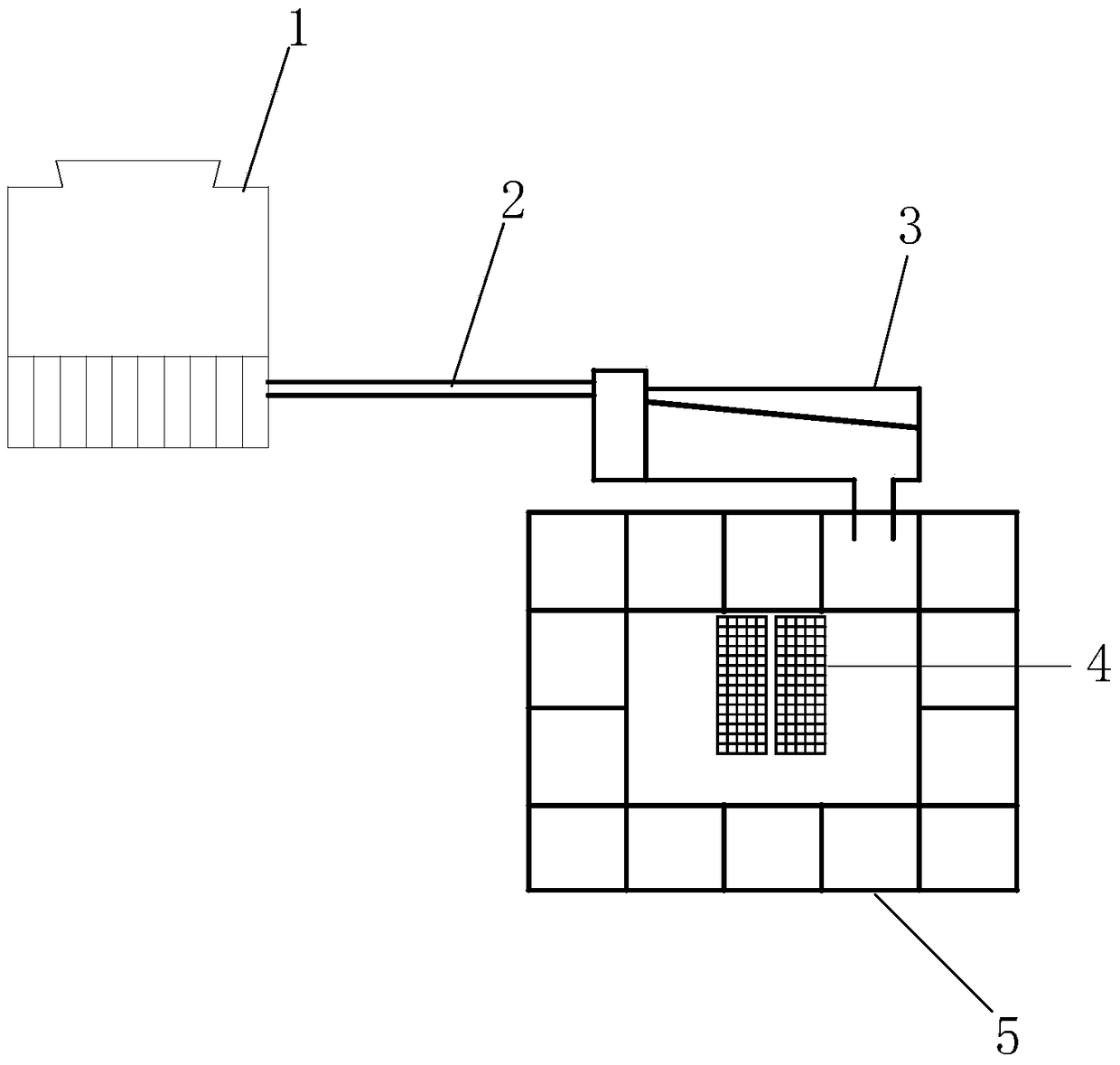

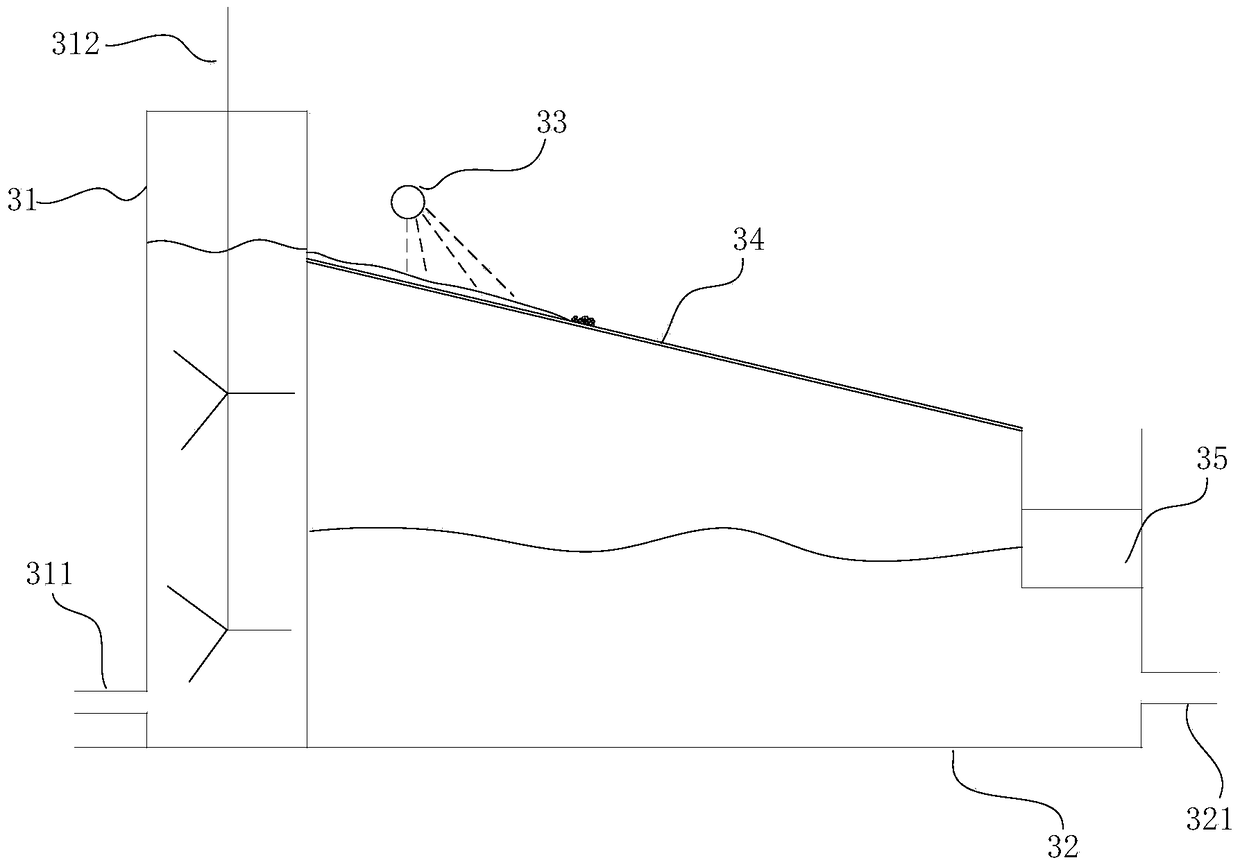

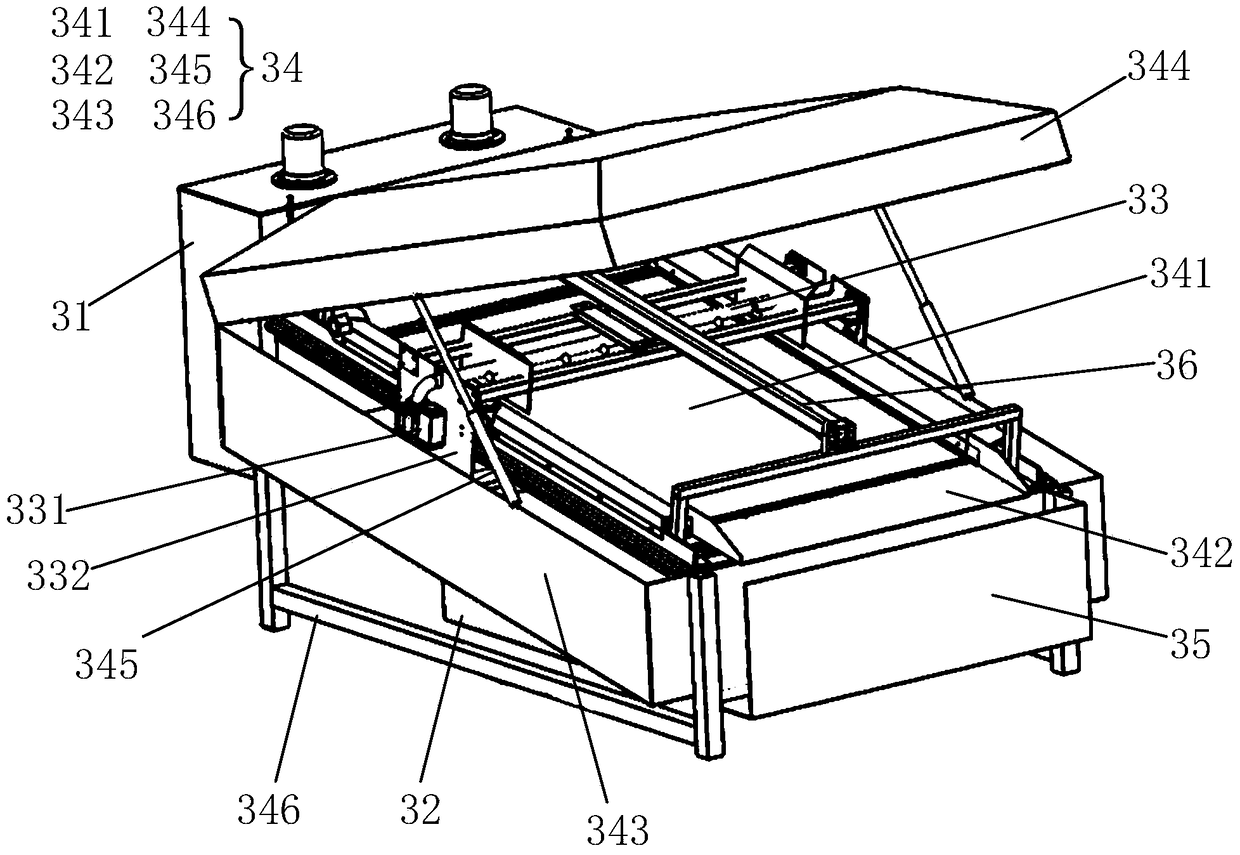

[0037] The following will combine Figure 1 to Figure 4 The circulating cooling water dialysis system provided by the present invention is described in detail, which is an optional embodiment of the present invention. It can be considered that those skilled in the art can modify and polish it within the scope of not changing the spirit and content of the present invention .

[0038] Please refer to figure 1 , the present invention provides a circulating cooling water dialysis system, including a cooling tower, a micron particle separator, an automatic calcium and magnesium ion adsorption stripper, and a circulating water tank;

[0039] The cooling tower is connected to the separator water inlet of the micron particle separator, and the separator water outlet of the micron particle separator is connected to the circulating water tank, and the liquid in the circulating water tank is automatically absorbed by the calcium and magnesium ions. The stripper realizes the adsorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com