Accurately controlled explosion-proof type automatic feeding device

An automatic feeding device, precise control technology, applied in the directions of loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of motor overheating and stop, unevenness, difficulty in accurately controlling the feeding weight, etc., to achieve safe and reliable use and strong connection. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict.

[0021] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

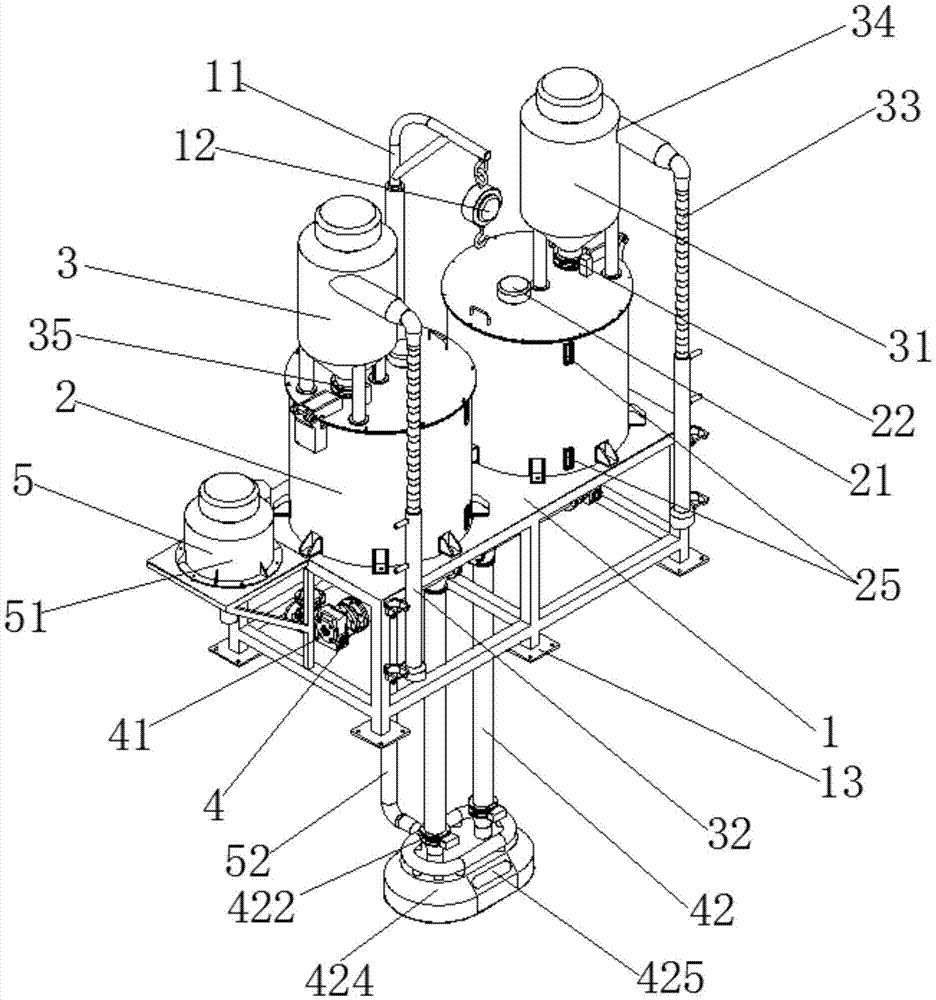

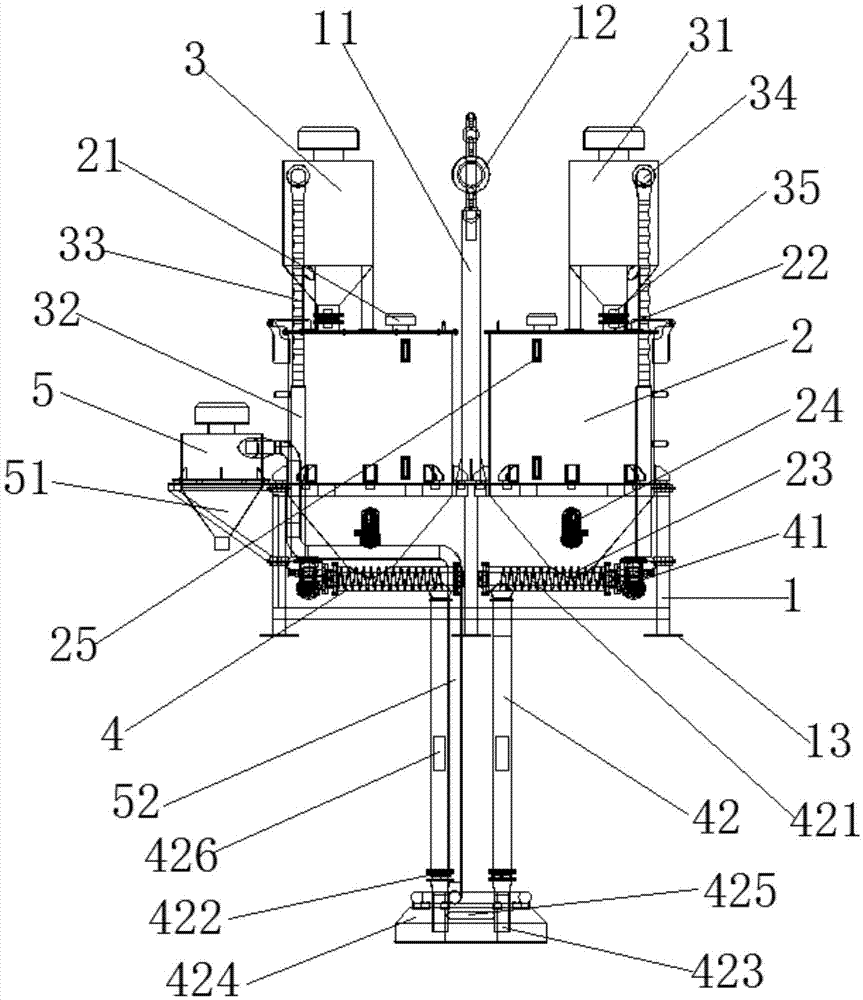

[0022] like figure 1 , 2 As shown, the present invention provides a precisely controlled explosion-proof automatic feeding device, including a platform support 1, a feeding container 2, a negative pressure feeding mechanism 3 and a screw feeding mechanism 4, and the feeding container 2 is arranged on the platform support. 1, the upper part of the feeding container 2 is provided with an exhaust filter port 21 and a feeding port 22, the lower part of the feeding container 2 is provided with a discharging port 23, and the inner wall of the accommodating cavity of the feeding container 2 is provided with The upper limit sensor and the lower limit sensor for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com