Horizontally-moving supporting frame applied to stone plate edge polishing device

A technology for traversing frames and edging, which is applied in the direction of machine tools, grinding workpiece supports, grinding machines, etc., which are suitable for grinding the edge of workpieces. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

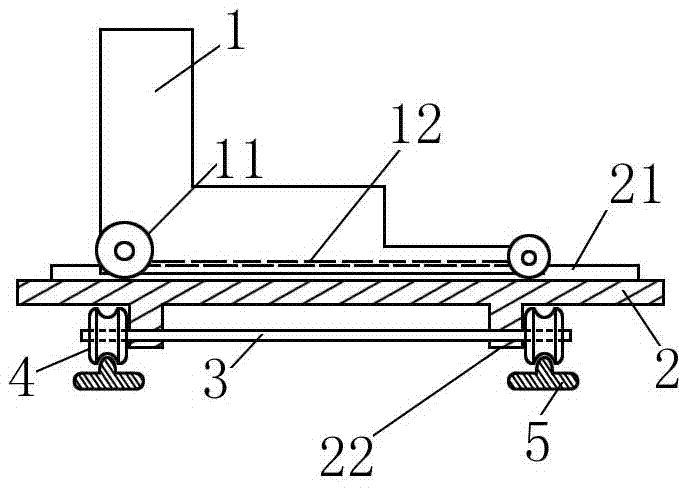

[0012] Such as figure 1 As shown, a support traverse frame used in a stone slab edging device is composed of a left and right moving support plate 1, a forward and backward moving support plate 2, multiple pairs of rollers, and a pair of rail steel 5. It is characterized in that,

[0013] The top surface of the left and right moving pallet 1 is provided with a step-by-step material receiving platform from left to right, and the bottom surface of the left and right moving pallet 1 is provided with multiple rail grooves 12 running left and right, and the front and rear sides of the left and right moving pallet 1 A first roller 11 is provided at the left and right bottom ends of the roller;

[0014] The top surface of the forward and backward moving support plate 2 is provided with a plurality of rails 21 running from left to right. Move the top surface of the support plate 2 forward and backward along the rail 21 to move left and right laterally;

[0015] A pair of rail steels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com