Glass position identification device of glass edging machine and glass position identification method thereof

An identification device and edge grinding machine technology, which is applied in the direction of grinding drive device, grinding machine tool parts, grinding automatic control device, etc., can solve problems such as low service life, fatigue damage of travel switch spring, and potential safety hazards. Achieve the effect of simple principle and improved applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

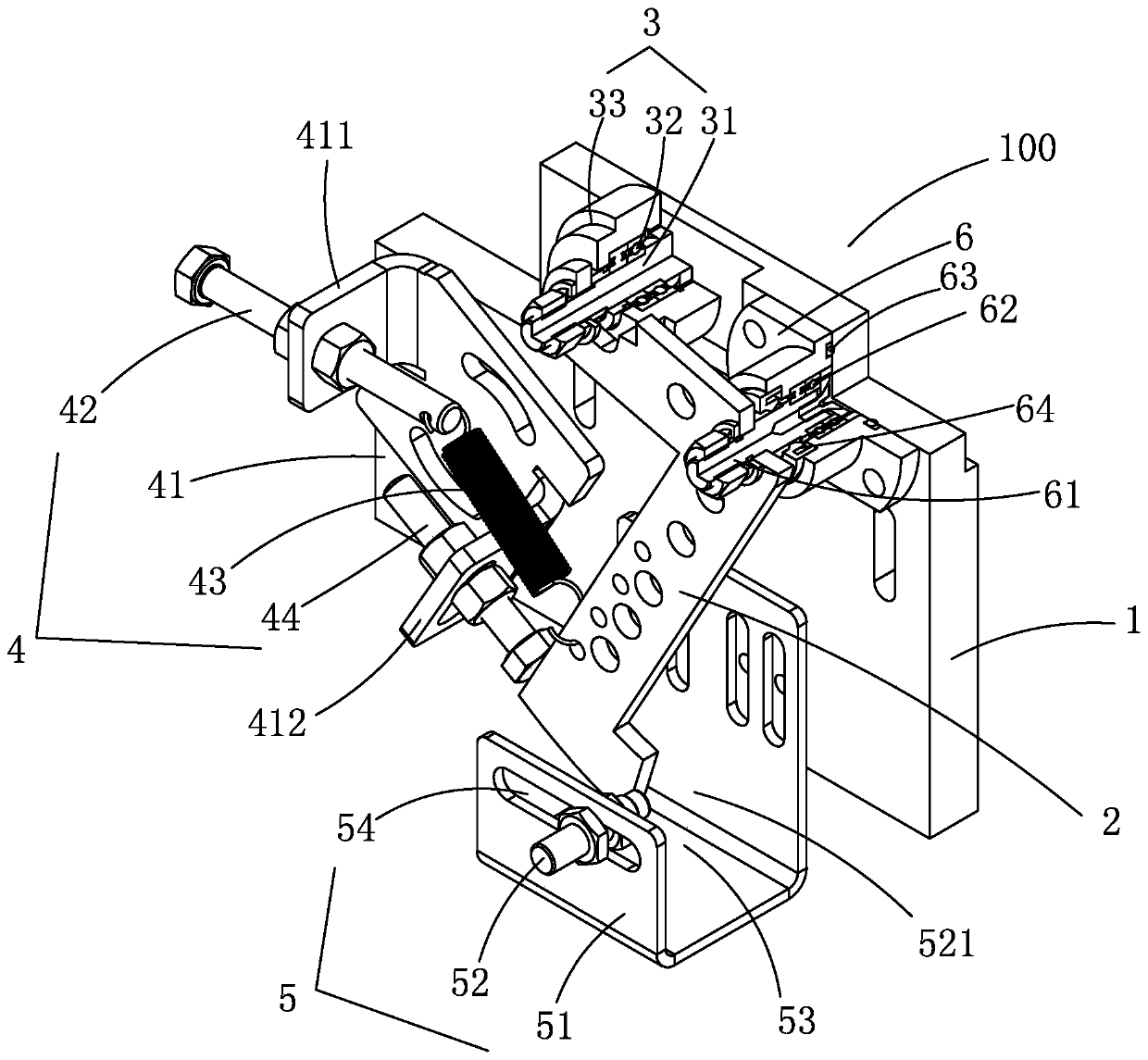

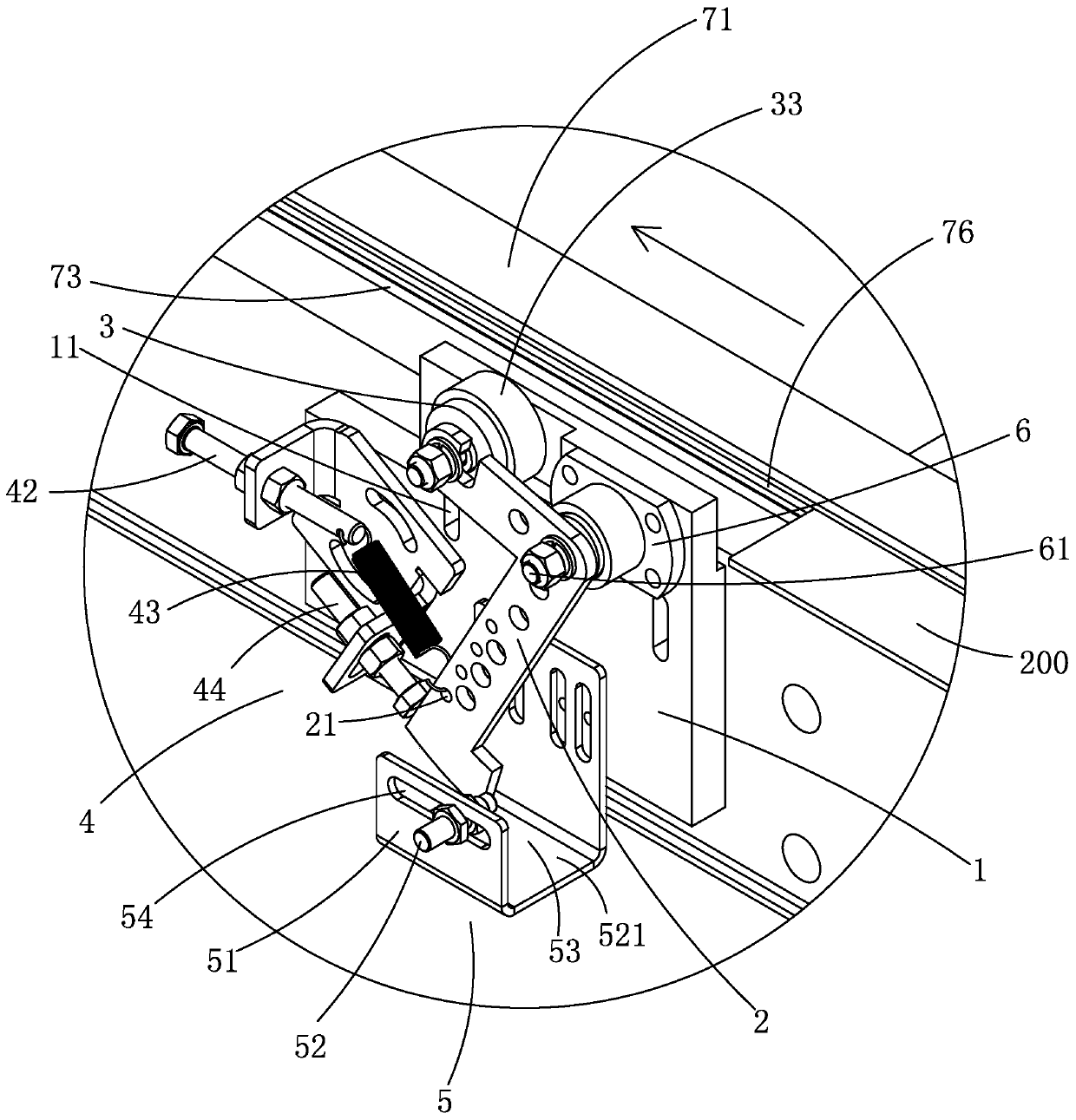

[0037] to combine Figure 1 to Figure 5 As shown, a glass position recognition device 100 for a glass edge grinder includes a base 1 , a swing rod 2 , a roller assembly 3 , an adjustment reset assembly 4 and a sensing assembly 5 .

[0038] The top of the base 1 has a chute 11 along its height direction, and the roller assembly 3 includes a roller shaft 31, a roller bearing 32 and a roller 33, and the roller shaft 31 is arranged on the chute 11 and moves up and down along the chute 11, The roller bearing 32 is sleeved on the roller shaft 31 , the roller 33 is sleeved on the roller bearing 32 , and the roller 33 rotates with the roller shaft 31 as the rotation center.

[0039] The induction component 5 includes a bracket 51 and a proximity switch 52. The bracket 51 is arranged at the bottom of the base 1. The bracket 51 has a slideway 53 for the swing rod 2 to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com