Process for machining pull ring mold

A mold processing and technology technology, which is applied in the field of pull ring mold processing technology, can solve the problems of smoke pollution, low efficiency, high cost, etc., and achieve the effect of improving processing efficiency and reducing smoke pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

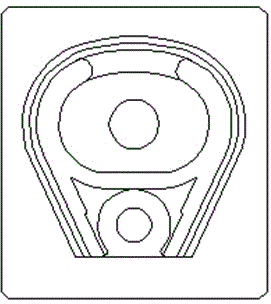

Image

Examples

Embodiment Construction

[0015] A ring pull mold processing technology:

[0016] a. Using SKD11 tool steel, vacuum heat treatment to make the material hardness meet the processing requirements of HRC58-60;

[0017] b. The raw material has a machining allowance of 0.3mm, and the precision grinding square is used to process the blank into an outer square shape, and the machining accuracy is within 0.01mm;

[0018] c. The outer square part processed in the previous step is used as the positioning reference plane, and the semi-finishing of the inner contour is formed on the machining center, using a ball cutter, leaving a machining allowance of 0.5mm, and the machine speed is controlled at 20000r / min, using three coordinates The measuring instrument detects the forming part;

[0019] d. Carry out vacuum heat treatment to make the workpiece reach HRC58-60;

[0020] e. The hexagonal square is used to process the outer square outline, leaving a margin of 0.02mm. The hexagonal square is processed to ensure ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap