Welding machine of inner ring board of steel pipe and application method thereof

An inner ring plate and steel pipe technology, applied in welding accessories, welding equipment, auxiliary welding equipment, etc., can solve the problems of inconvenient welding method of the inner wall ring plate of the steel pipe, increasing the number of pipe butt joints, and increasing the labor intensity of workers, etc. The effect of good welding quality, reduced labor intensity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

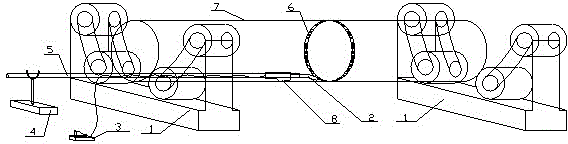

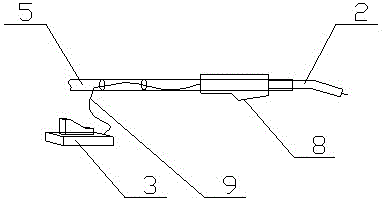

[0031] figure 1 It is a structural schematic diagram of a steel pipe inner ring plate welding machine according to an embodiment of the present invention;

[0032] figure 2 It is a structural schematic diagram of a handle and an arc strike switch according to an embodiment of the present invention. As shown in the figure, the steel pipe inner ring plate welding machine includes a tire rotating mechanism supported on the rotating tire 1 and driving the steel pipe 7 to rotate, a welding torch and a welding torch control mechanism. It is characterized in that: the welding torch control mechanism includes a bracket, Welding handle and arc ignition switch, wherein: the bracket 4 is an iron pier bracket, which is arranged outside the mouth of the steel pipe 7 to be welded; the welding handle 5 is a metal pipe whose length is greater than that of the inner ring plate 6 of the steel pipe and away from the steel pipe 7 One end of the welding handle firmly fixes the welding torch 2, ...

Embodiment 2

[0034] A method for using a steel pipe inner ring plate welding machine, characterized in that it comprises the following steps:

[0035] a. Firmly fix the torch on one end of the handle;

[0036] b. The operator uses the handle to transport the welding torch on one end of the handle to the welding position, and makes the other end of the handle rest on the bracket 4;

[0037] c. Start the tire rotating mechanism supported on the rotating tire 1 and drive the steel pipe 7 to rotate to allow the steel pipe to rotate;

[0038] d. The operator presses the arc ignition switch provided on the welding handle 5 to start welding, and the arc ignition switch (3) is a push-type switch.

[0039] When working, the rotating tire provides power for the steel pipe, and the rotating tire itself is driven by the motor. The rotating tire makes the pipe rotate during welding, which not only effectively prevents the welding torch from moving, but also rotates at a uniform speed to make the weld ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com