Lifting-free electric tool rest

A tool holder, electric technology, applied in metal processing equipment and other directions, can solve the problems of poor sealing of the tool holder, parts that do not meet the requirements of use, poor impact resistance, etc., and achieve the effect of solving sealing problems, reasonable design, and eliminating interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

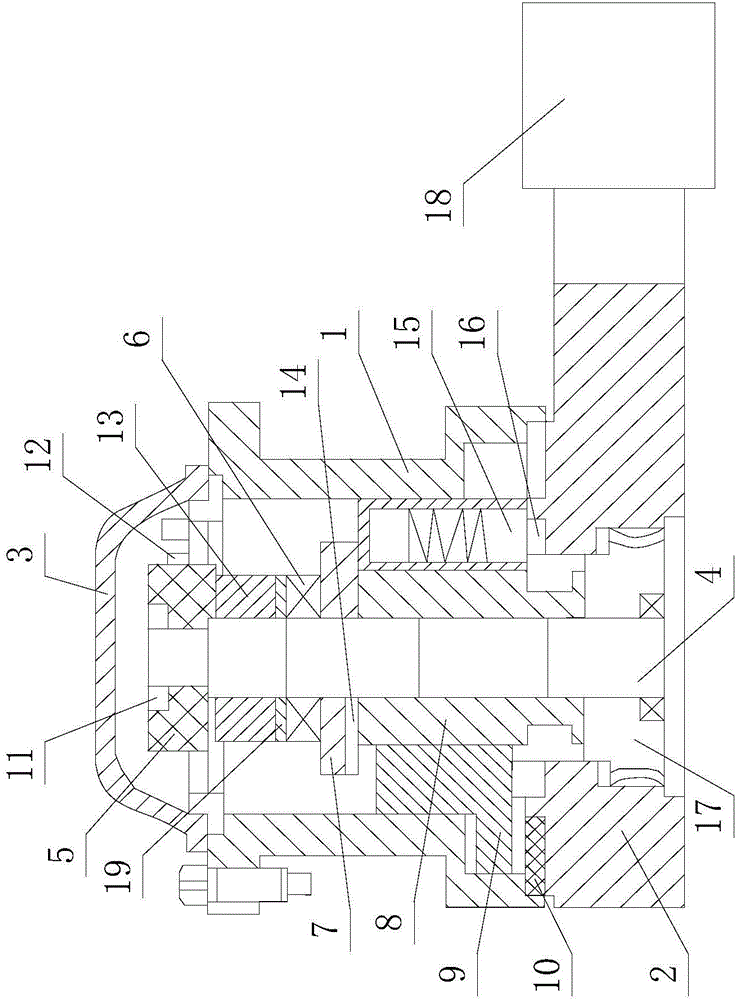

[0014] The present invention will now be further described in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0015] like figure 1 The lift-free electric knife holder shown includes an upper knife body 1 and a lower knife body 2 arranged up and down, and an upper cover 3 is arranged above the upper knife body 1, and the upper knife body 1 and the lower knife body 2 are in contact with each other. The outer end teeth 10 are arranged on the part, and the central axis 4 is vertically arranged in the center of the cavity formed by the upper cover 3, the upper cutter body 1 and the lower cutter body 2; , large nut 13, stop ring 6, clutch disc 7, screw rod 8 and worm wheel 17, clutch pin 14 is installed at the bottom of clutch disc 7; one side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com