Method for preparing chemical and magnetic ordered-phase nanoparticles

A magnetic nanoparticle and nanoparticle technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of increasing process steps and increasing the preparation cost, and achieves the advantages of avoiding agglomeration, low cost and good application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

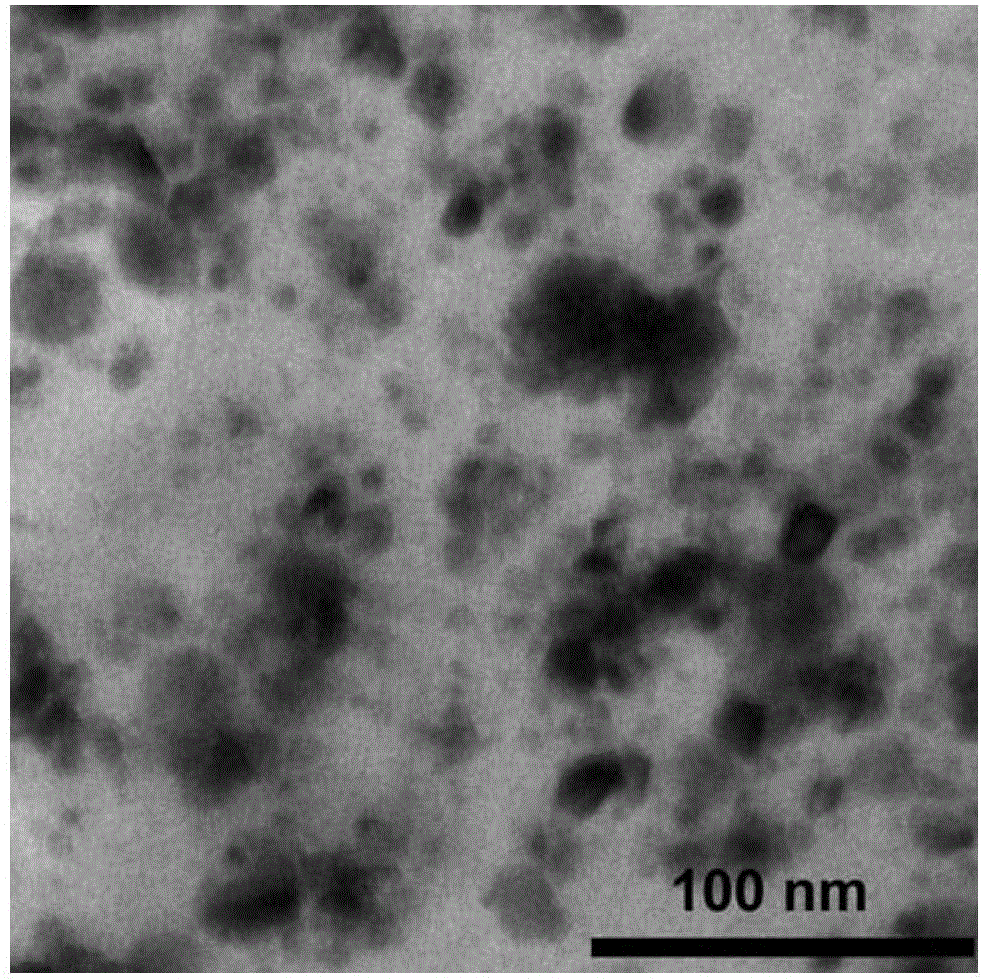

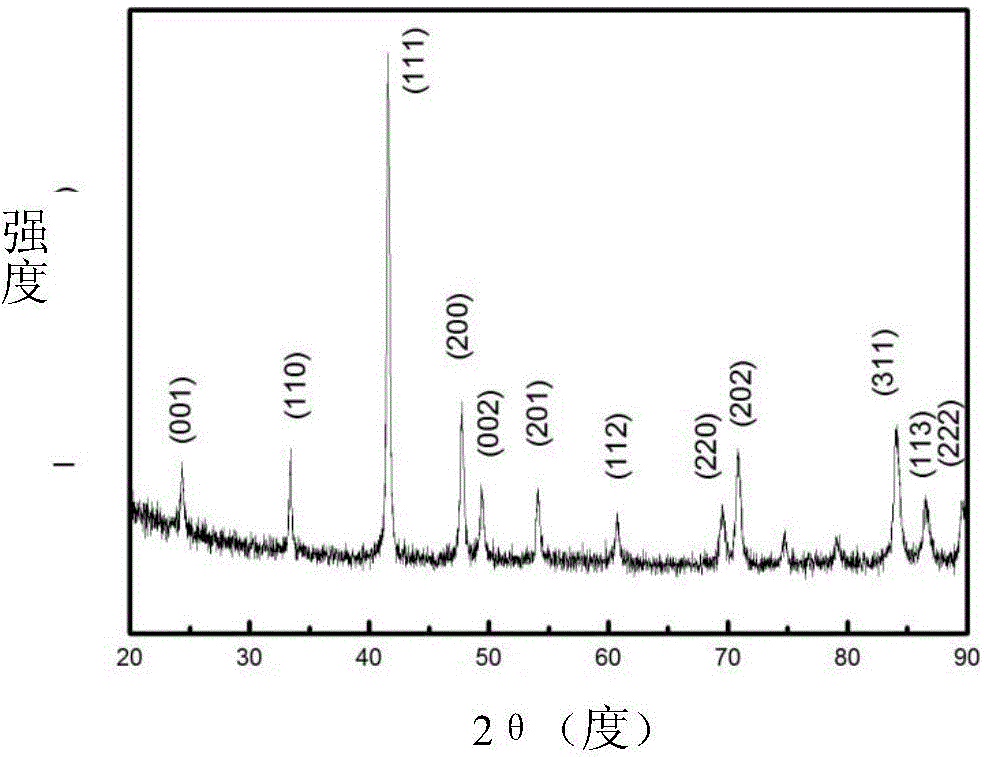

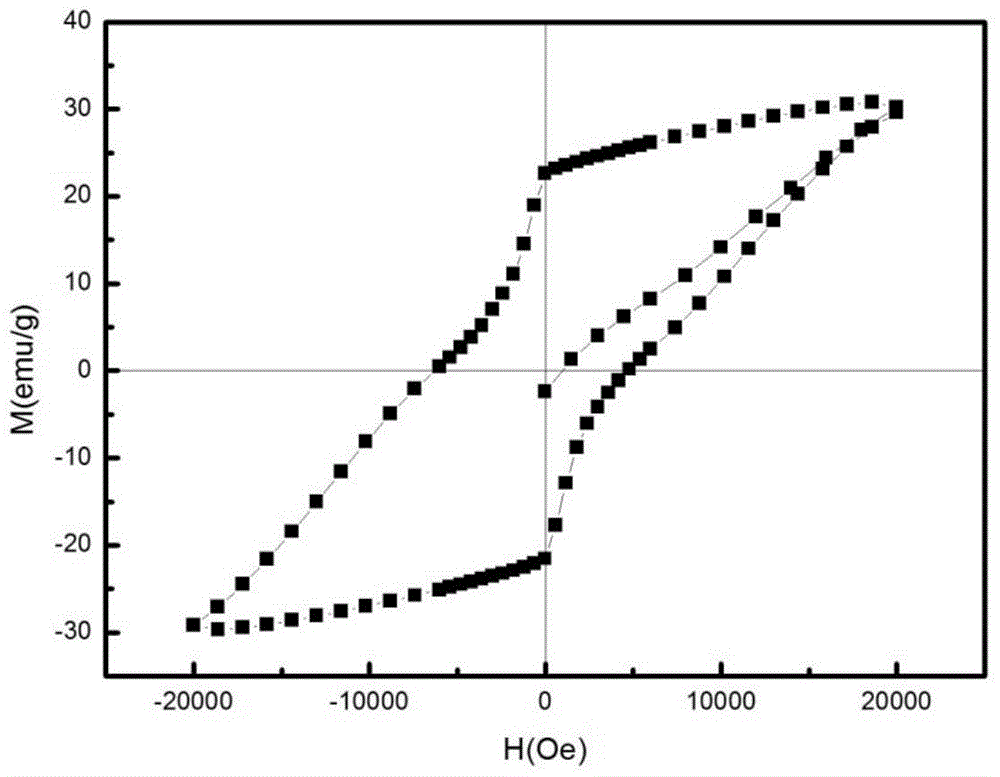

[0035] (1) Take 1mol NaCl, after drying in a vacuum drying oven, add 25ml of n-heptane and put it into a planetary ball mill for ball milling for 2 days to obtain NaCl powder with a particle size below 20 microns;

[0036] (2) the iron acetylacetonate of 0.75mmol and the platinum acetylacetonate of 0.5mmol are mixed with the NaCl powder that step (1) obtains together for 10h;

[0037] (3) Take out the mixed powder and dry it and put it into the ark, and then place it in a tube annealing furnace for calcination. The tube annealing furnace first uses Ar gas to remove the air, and then feeds Ar and H during heating. 2 Mixed gas of Ar and H 2 The volume percentage is 95:5, the mixed gas flow rate is 10ml-400ml / min, the temperature rise rate is controlled at 10°C / min, the temperature is raised to 750°C and then kept for 1 hour, and after the heat preservation is completed, it is cooled to room temperature under the protection of the atmosphere to obtain the calcined product ;

[...

Embodiment 2

[0041] (1) Take 1mol NaCl, after drying in a vacuum drying oven, add 25ml of n-heptane and put it into a planetary ball mill for ball milling for 2 days to obtain NaCl powder with a particle size below 20 microns;

[0042] (2) the iron acetylacetonate of 1mmol and the platinum acetylacetonate of 0.5mmol are mixed with the NaCl powder that step (1) obtains together for 10h;

[0043](3) Take out the mixed powder and dry it and put it into the ark, and then place it in a tube annealing furnace for calcination. The tube annealing furnace first uses Ar gas to remove the air, and then feeds Ar and H during heating. 2 Mixed gas of Ar and H 2 The volume percentage is 95:5, the mixed gas flow rate is 10ml-400ml / min, the temperature rise rate is controlled at 10°C / min, the temperature is raised to 650°C and then kept for 1 hour, and after the heat preservation is completed, it is cooled to room temperature under the protection of the atmosphere to obtain the calcined product ;

[0044...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com