Waste water circulating and recycling device for medicine bottle cleaning machine

A waste water recycling and bottle washing machine technology, which is applied in the fields of cleaning hollow objects, cleaning methods and utensils, water/sewage multi-stage treatment, etc. , to achieve the effect of cost saving, convenient popularization and easy mastery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

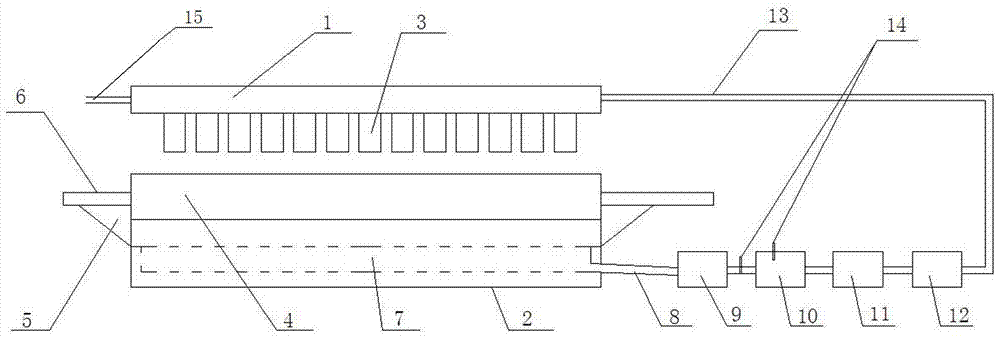

[0021] A device for recycling waste water from a bottle washing machine for medicines, comprising a spraying station 1 and a cleaning station 2, characterized in that the spraying station 1 is located above the cleaning station 2, and the bottom of the spraying station 1 is provided with a plurality of spraying stations. Showering device 3, the side of described spray platform 1 is provided with water inlet pipe 15; The top surface of described cleaning platform 2 is provided with medicine bottle conveying platform 6, and the two sides of described cleaning platform 2 are located at the bottom of medicine bottle conveying platform 6 and are provided with connection. Sink 5, the top surface of the cleaning table 2 is located on both sides of the medicine bottle delivery table 6 and is provided with baffles 4; Connect the solid filter 9, the solid filter 9 is connected to the liquid neutralization filter 10, the liquid neutralization filter 10 is connected to the sterilization ...

Embodiment 2

[0027] Working principle of the present invention: in the present invention, the water inlet pipe 15 on the spray table 1 transports the water that adds detergent, sprays downwards through the spray device 3, and carries out the pipeline-type delivery of the medicine bottle to be cleaned on the medicine delivery table, cleaning Platform 2 effectively recovers the liquid sprayed in the spraying device 3 to the waste liquid recovery pool 7 through the baffle plate 4 and the water receiving tank 5, and the waste liquid recovery pool 7 passes the waste liquid through the solid filter device 9 for impurity removal and filtration. The liquid neutralization and filtering device 10 performs neutralization and removal of impurities, sterilizes through the sterilizing pool 11 , and performs inspection and recycling through the recovery test pool 12 .

Embodiment 3

[0029] In the present invention, a liquid injection pipeline may be provided on the liquid neutralization filter device 10 to facilitate the injection of liquids such as acid and alkali to neutralize the pH value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com