Three-in-one kettle structure

A three-in-one, kettle body technology, applied in the direction of filtration separation, membrane filter, fixed filter element filter, etc., can solve the problems of low work efficiency, poor washing effect, poor working environment, low heat transfer coefficient, etc., and achieve improved filtration The effect of efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

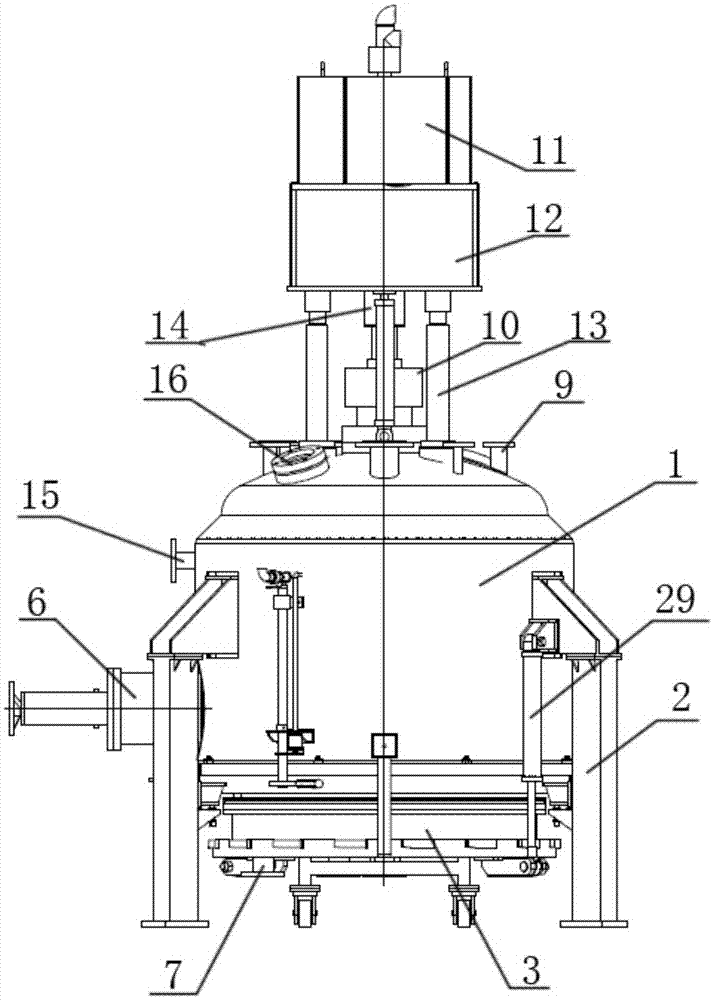

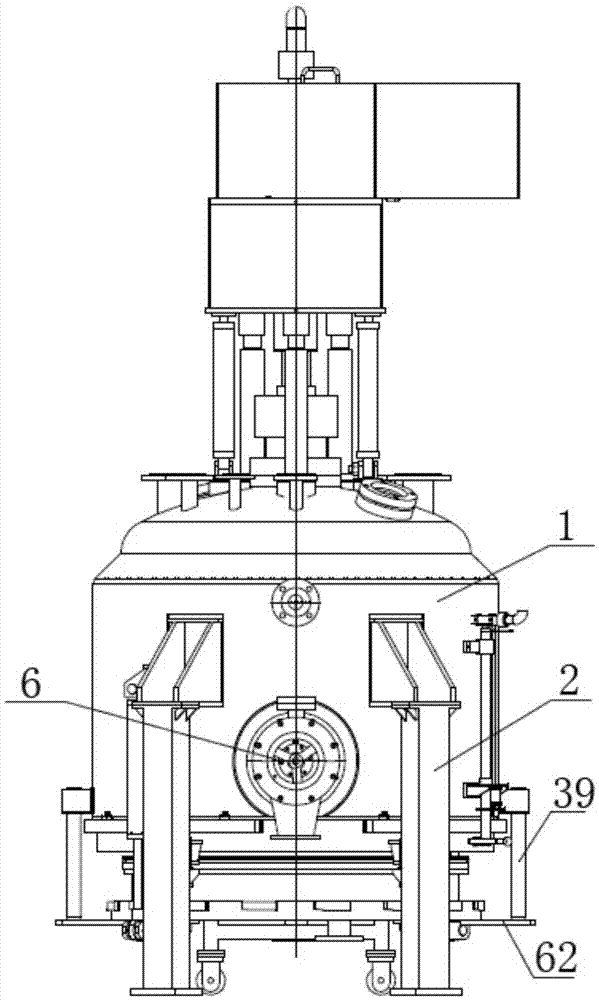

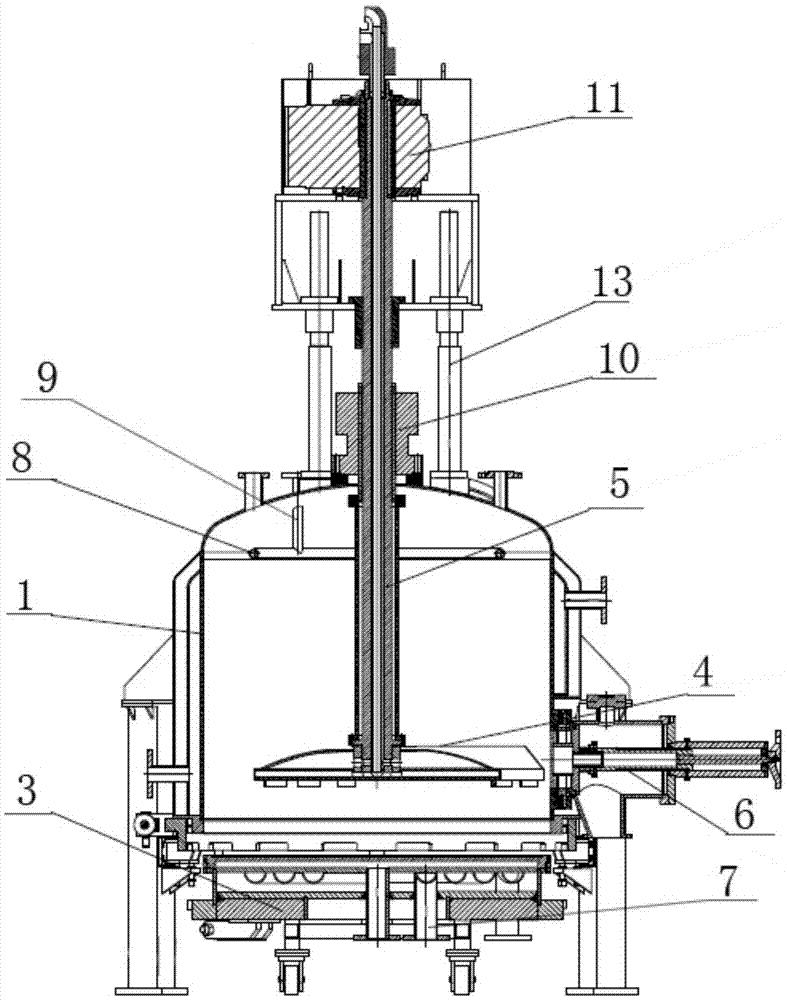

[0034] A three-in-one kettle structure, see Figure 1 to Figure 15 : It includes a kettle body 1, a plurality of vertically arranged support feet 2 are arranged on the outside of the kettle body 1, a lower head 3 is arranged directly below the bottom end surface of the kettle body 1, and a stirring paddle is arranged inside the kettle body 1 4. The stirring shaft 5 penetrates the top of the kettle body 1 and then is fastened to the center of the stirring paddle 4. The middle and lower part of the kettle body 1 is provided with a discharge mechanism 6, and the lower head 3 is arranged with a suction filter port 7. The lower head 3 is the filter heating chassis, the upper part of the inner cavity of the kettle body 1 is arranged with a spray device 8, the spray device 8 is externally connected to an external water source through the connecting pipe 9, and a sealing device 10 is arranged between the stirring shaft 5 and the top of the kettle body 1, The top of the stirring shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com