A rear throw type grass and soil separation shallow loosening shovel

A grass-soil and separator technology, which is applied in the field of agricultural machinery, can solve the problems of increased environmental pollution, farming costs, poor grass-soil separation effect, and low weed killing rate, so as to improve the grass-soil separation ability, grass-soil Good separation effect and high weed removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

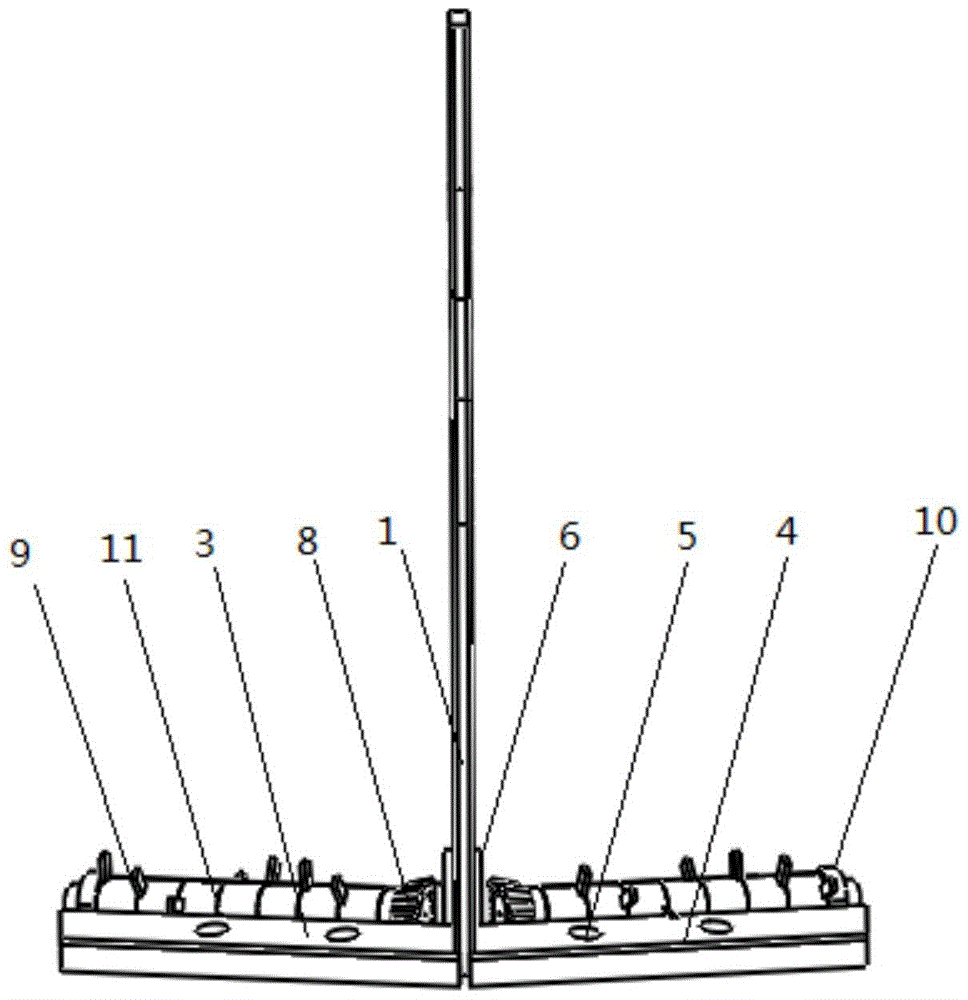

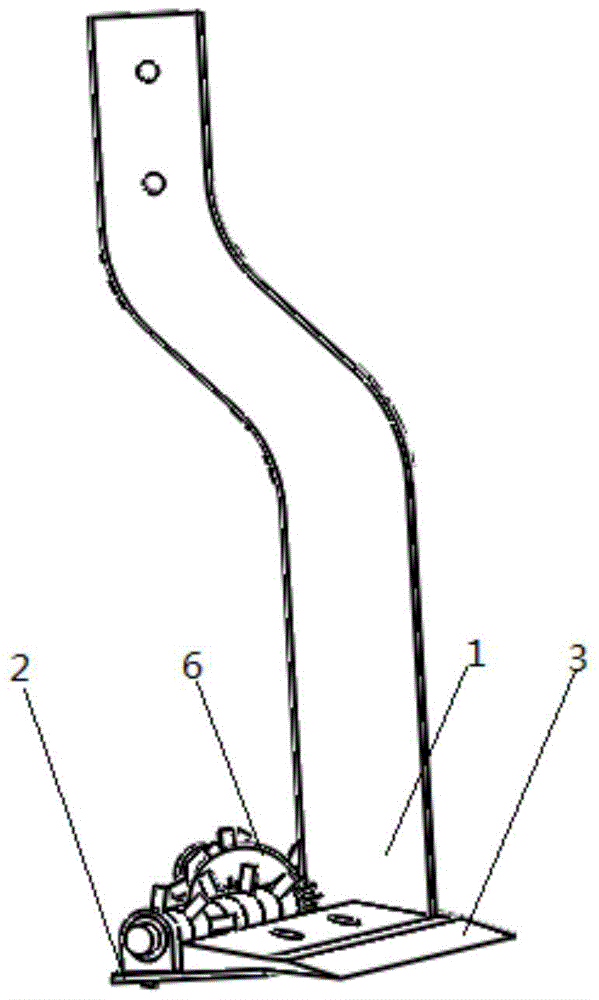

[0028] Such as Figure 1-Figure 5 Shown is a rear-throwing shovel for separating grass and soil, which includes a shovel frame for shoveling, a driving device, a power transmission device, shovel wings for shoveling and a separator for grass and soil.

[0029] The shallow loosening shovel frame includes the shovel handle 1, the left and right shallow shovel support plates 2 and the drive wheel bracket. The left and right shallow shovel support plates 2 are symmetrically welded on both sides of the bottom end of the shovel handle 1 at an angle of 140°. Shallow loose shovel support plate 2 bottom surfaces are flush, and the driving wheel bracket is welded on the back of shovel handle 1 bottom.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com