A high-pressure conveying slip ring device for propeller plasma flow control

A plasma and flow control technology, applied in the direction of rotating current collectors, current collectors, electrical components, etc., can solve the problems of breakdown air arc, difficult to assemble and fix the propeller hub, prevent breakdown phenomenon, enhance reliability performance, the effect of increasing the creepage distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

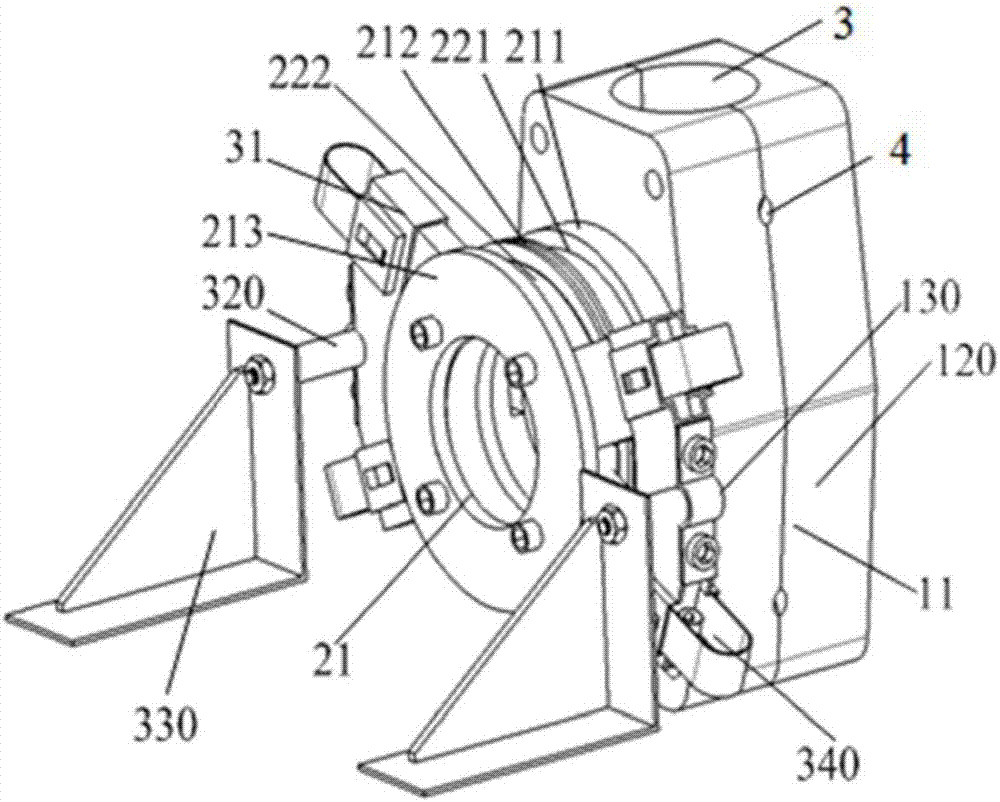

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

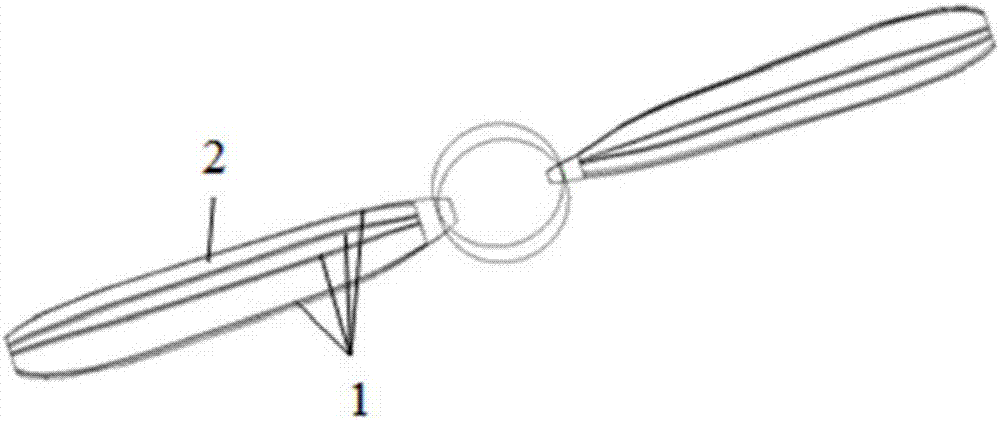

[0037] A high-pressure delivery slip ring device for propeller plasma flow control, comprising:

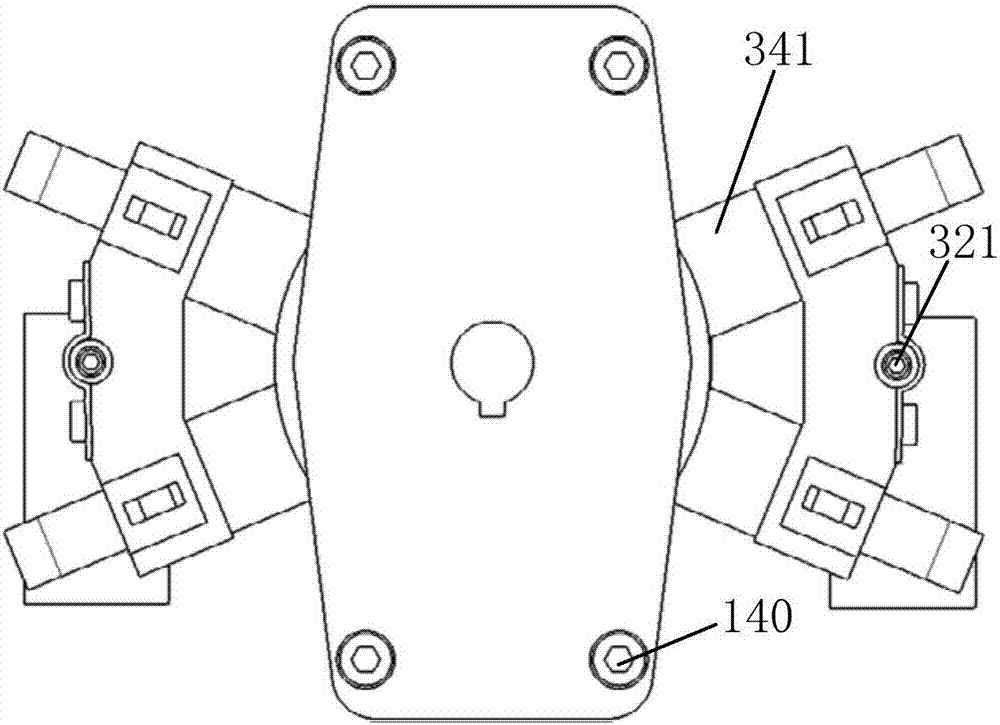

[0038]The propeller hub 11 is installed on the propeller power shaft. The propeller hub 11 includes a propeller hub front end cover 120 and a propeller hub rear end cover 130. The propeller hub front end cover 120 and the propeller hub rear end cover of the propeller hub 11 130 is assembled and fixed by 4 hexagon socket bolts A140. Both the hub front end cover 120 and the hub rear end cover 130 include an end face and an assembly surface, and blade assembly surfaces are provided at the upper and lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com