Method for assembling fuel cell stack

A fuel cell stack and assembly method technology, applied in the direction of fuel cell grouping, fuel cells, circuits, etc., can solve the problems of single cell offset, poor contact, distortion and deformation of ultra-thin flow field plates, etc., to achieve dimensional stability, The effect of simple design and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The content of the present invention is illustrated below in conjunction with the accompanying drawings and embodiments.

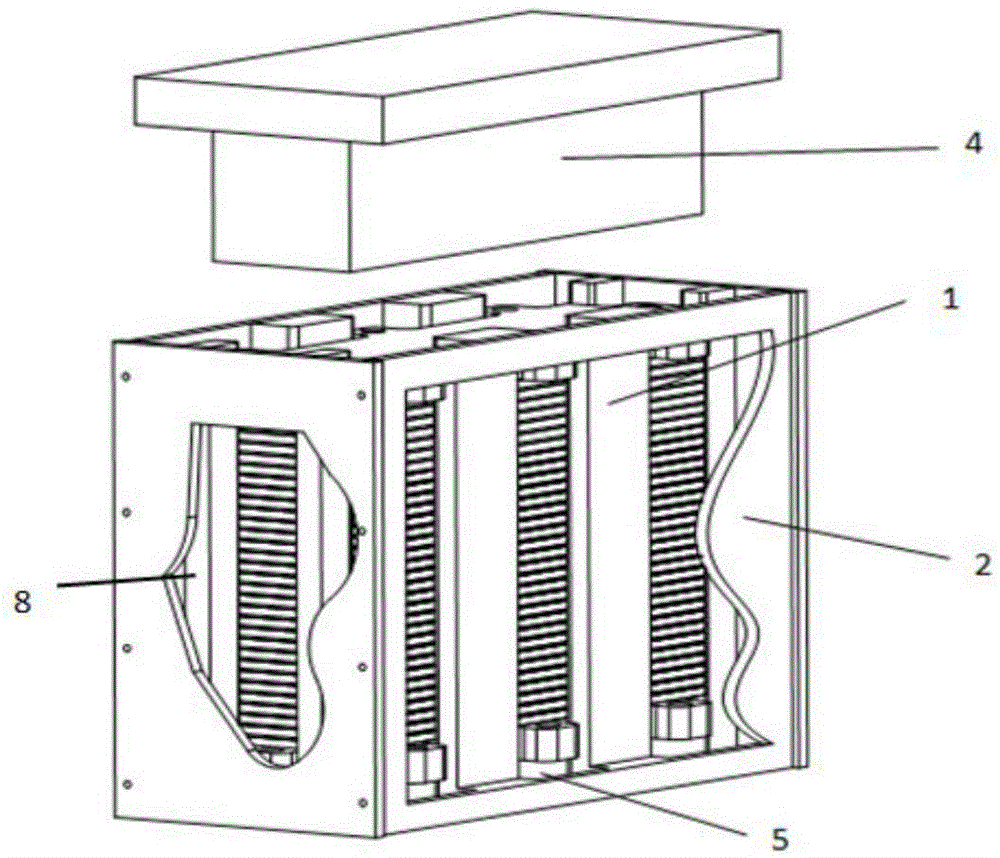

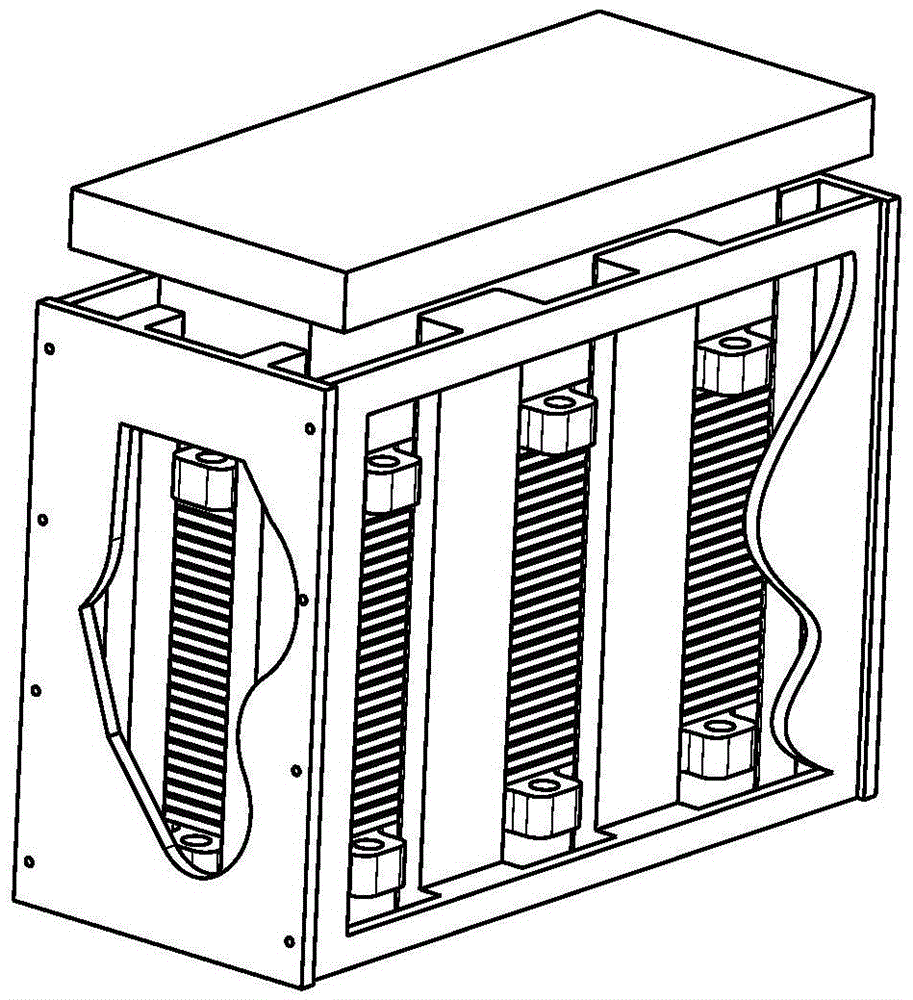

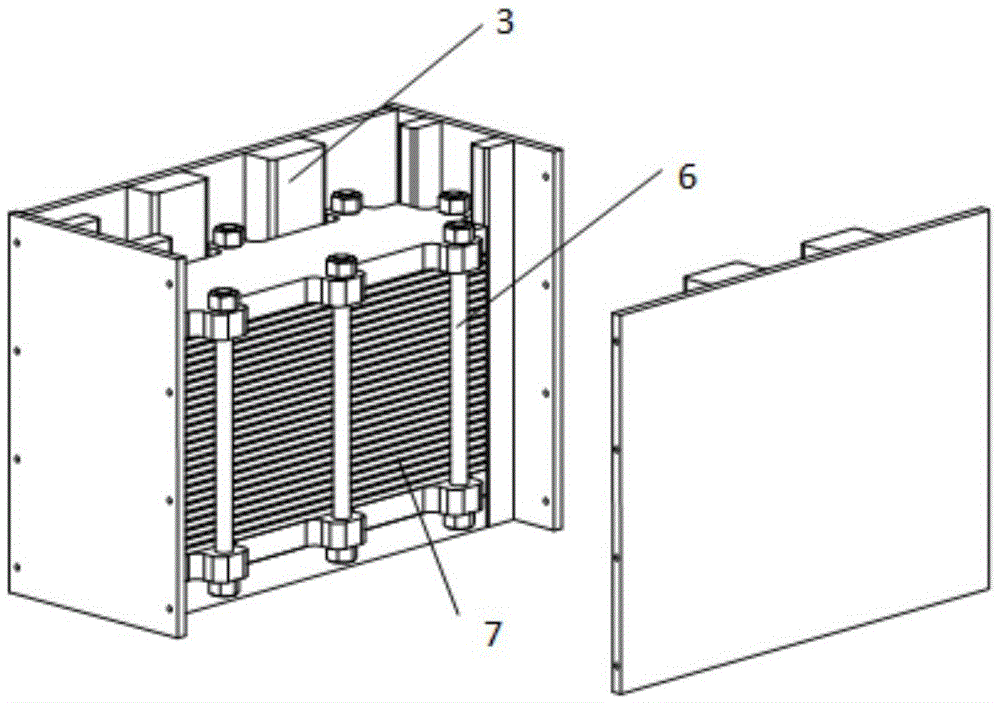

[0032] Such as Figure 1 to Figure 4 As shown, the embodiment of the present invention provides an assembly device for a fuel cell stack, which includes a fixing mechanism, a positioning mechanism, a pressure supply device and a locking mechanism.

[0033] In this embodiment, the fixing mechanism is the fixing frame 2 . The positioning mechanism includes multiple sets of positioning columns, each group of positioning columns includes at least two positioning columns 1, and each group of positioning columns is respectively fixed on the inner surface of each side plate of the fixed frame 2, which can be fixed by means of screws. Each positioning column 1 includes a first surface 8 and a second surface 3 parallel to each other, and the first surface 8 of each positioning column 1 is in contact with the inner surface of the side plate of the fixing fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com