Statistical Process Control Method for Batch Processing of Wafers

A technology of statistical process control and batch processing, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as false alarms, second-order nesting complexity, improvement, etc., and achieve the effect of improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The following is a further description of the present invention by taking the batch processing of wafers for producing 3AQ151024 integrated circuit chips as an example in conjunction with the drawings.

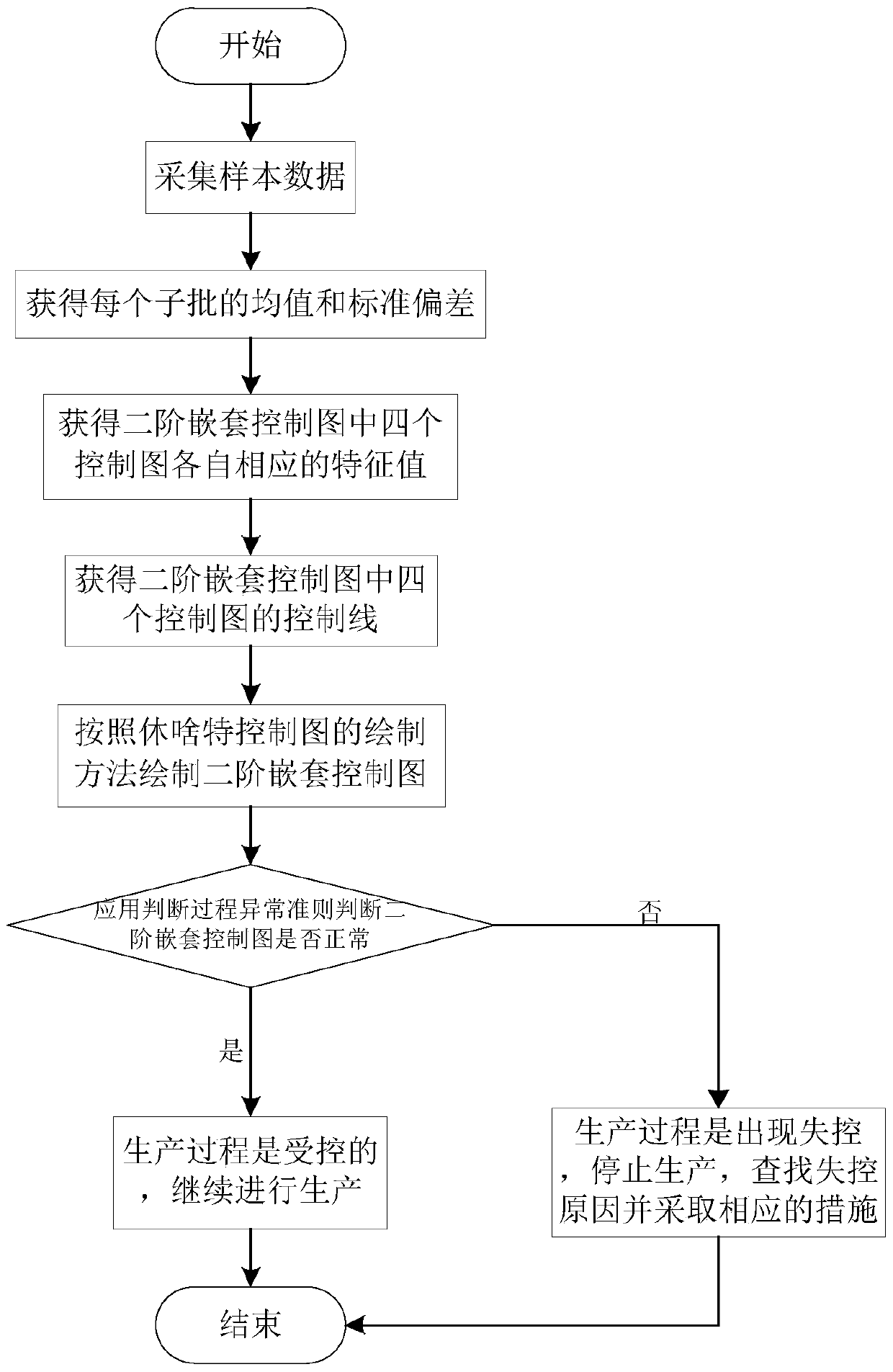

[0055] Reference figure 1 , The implementation steps of the present invention are as follows:

[0056] Step 1: Collect samples.

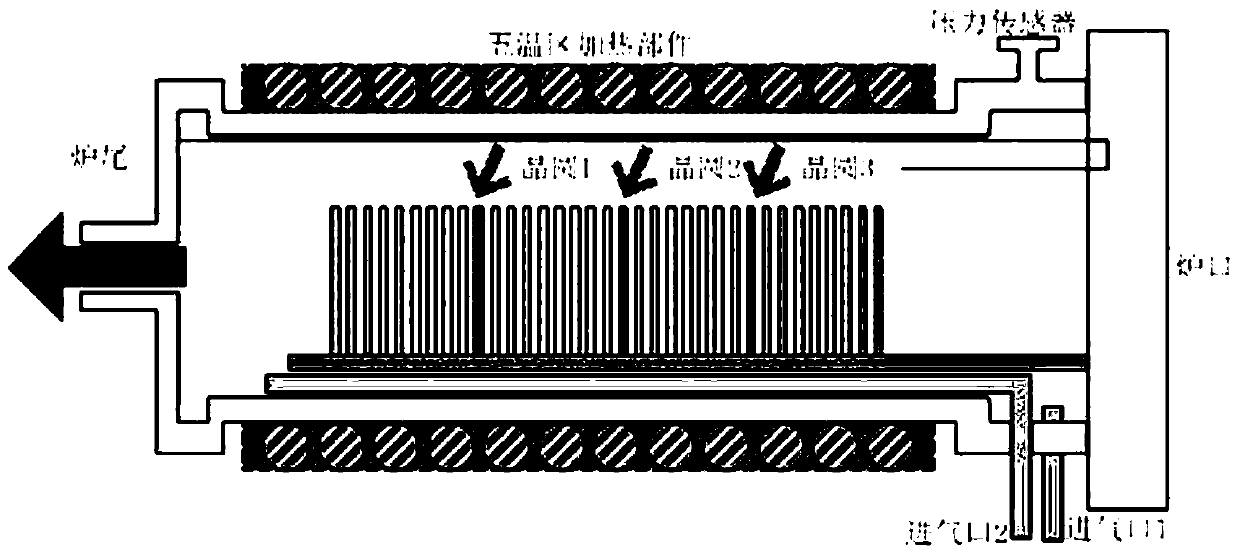

[0057] 1.1) Place the 3AQ151024 integrated circuit chip wafer in a diffusion furnace numbered 11C for bulk phosphorus diffusion;

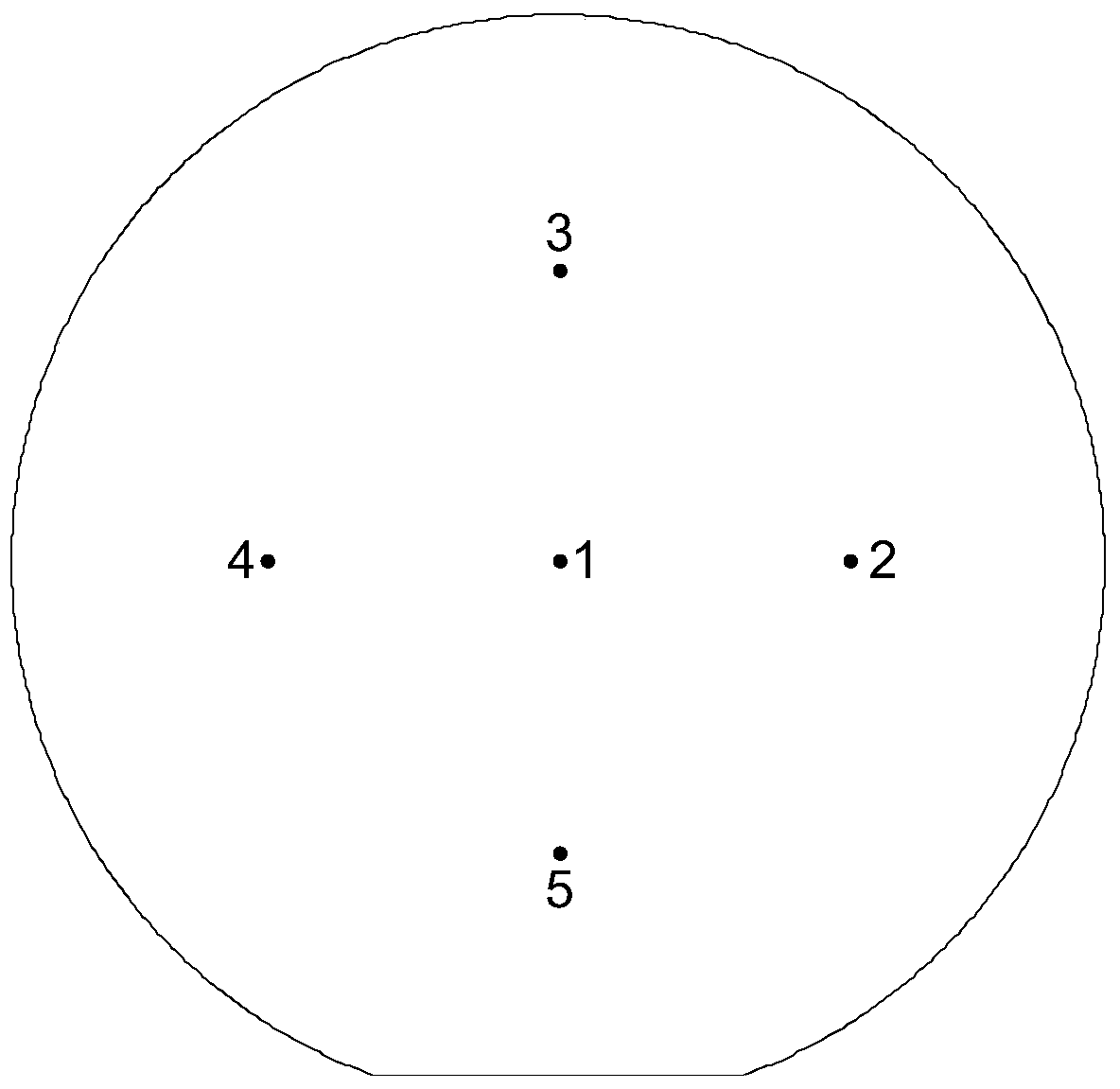

[0058] 1.2) After the phosphorus is diffused, first select such as figure 2 3 wafers are extracted from the 3 fixed positions shown; then the square resistance is measured at the 5 fixed positions on the extracted wafer for sample data collection, such as image 3 Shown

[0059] 1.3) 25 batches of sample data are obtained after 25 consecutive collections. Each batch has 3 sub-batch and each sub-batch has 5 sample data. As shown in Table 1, record the l sample data of the jth subbatch of the i batch X ijl , Where i=1, 2,....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com