Thermo-tube drying storehouse capable of utilizing afterheat

A drying chamber and heat pipe technology, applied in the field of drying chambers, can solve the problems of inability to cool, unfavorable storage of high-temperature materials, unutilized heat energy, etc., achieve energy-saving drying of materials, optimize drying quality, and prevent agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

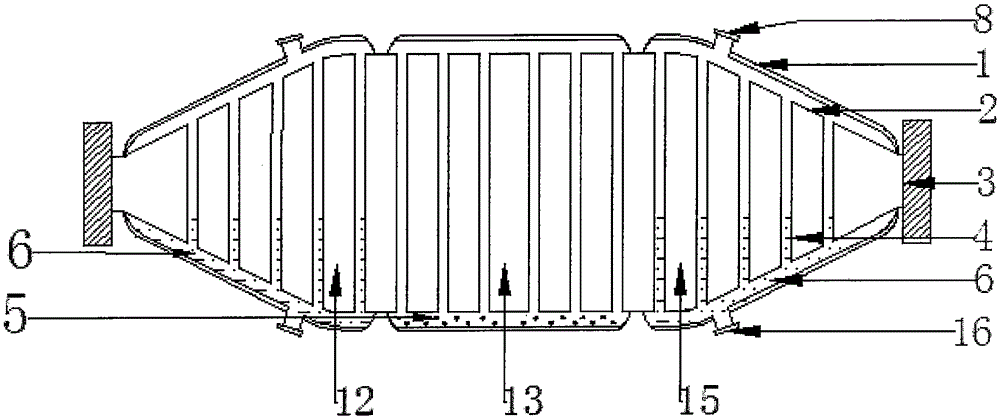

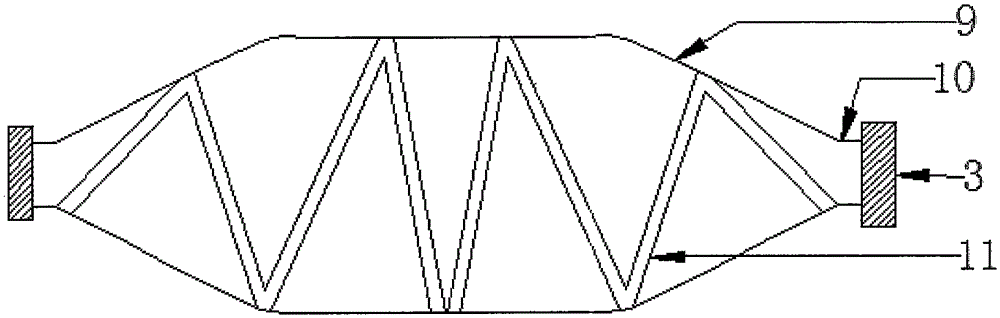

[0050] Such as figure 1 The shown heat pipe drying bin that can utilize waste heat consists of an outer shell (1), an inner bin (2), a discharge device (3), a heat-conducting medium (6) and a heat-conducting working medium (5).

[0051] The appearance shape of the heat pipe drying bin that can utilize waste heat is cylindrical.

[0052] 1. Both ends of the heat pipe drying chamber that can utilize waste heat are tapered.

[0053] 2. There are inlet and outlet ports (10) at both ends of the inner chamber (2) of the heat pipe drying chamber that can utilize waste heat.

[0054] 3. The outer diameter of the heat pipe drying chamber that can utilize waste heat is 1500mm.

[0055] 4. The length of the heat pipe drying chamber that can utilize waste heat is 15000mm.

[0056] The material of the shell (1) is a metal plate, and the thickness of the metal plate is 1mm.

[0057] The interior of the inner chamber (2) is divided into a preheating section (15), a drying section (13) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com