Polyisocyanates composition, coating composition, and coating method

A technology of polyisocyanate and diisocyanate, which is applied in the field of polyisocyanate composition, can solve the problems of bad influence of combustion catalyst and different effects, and achieve the effect of excellent coating film appearance and high curing property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

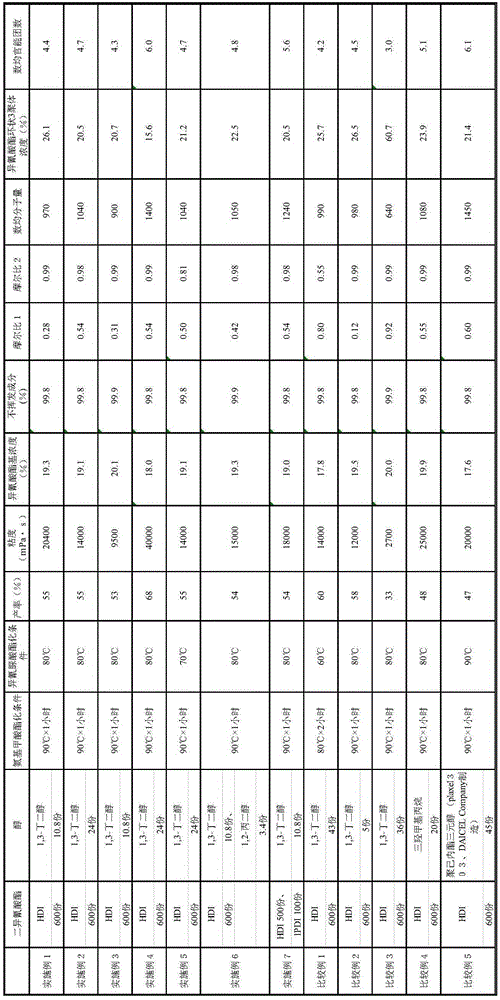

Embodiment 1

[0108] A 4-neck flask equipped with a stirrer, a thermometer, a reflux condenser, and a nitrogen blowing tube was made into a nitrogen atmosphere, and 600 parts of HDI and 10.8 parts of 1,3-butanediol as a dihydric alcohol were put in, and the temperature in the reactor was lowered under stirring. It maintained at 90 degreeC for 1 hour, and performed the urethanization reaction. After that, the temperature in the reactor was kept at 80°C, 0.03 part of tetramethylammonium octanoate was added as an isocyanurate catalyst, and the refractive index of the reaction solution was measured. When the yield became 55%, phosphoric acid was added to stop the reaction. . After filtering the reaction solution, unreacted HDI was removed using a thin film evaporation tank. 343 g of the obtained polyisocyanate composition had a non-volatile content of 99.8% by mass, a viscosity at 25°C of 20400 mPa·s, an isocyanate group concentration of 19.3% by mass, a diisocyanate monomer concentration of 0...

Embodiment 2

[0110] A 4-neck flask equipped with a stirrer, a thermometer, a reflux condenser, and a nitrogen blowing tube was made into a nitrogen atmosphere, and 600 parts of HDI and 24 parts of 1,3-butanediol as a dihydric alcohol were put in, and the temperature in the reactor was lowered under stirring. It maintained at 90 degreeC for 1 hour, and performed the urethanization reaction. After that, the temperature in the reactor was kept at 80°C, 0.03 part of tetramethylammonium octanoate was added as an isocyanurate catalyst, and the refractive index of the reaction solution was measured. When the yield became 55%, phosphoric acid was added to stop the reaction. . After filtering the reaction solution, unreacted HDI was removed using a thin film evaporation tank. 343 g of the obtained polyisocyanate composition had a nonvolatile content of 99.8% by mass, a viscosity at 25°C of 14000 mPa·s, an isocyanate group concentration of 19.1% by mass, a diisocyanate monomer concentration of 0.09...

Embodiment 3~7

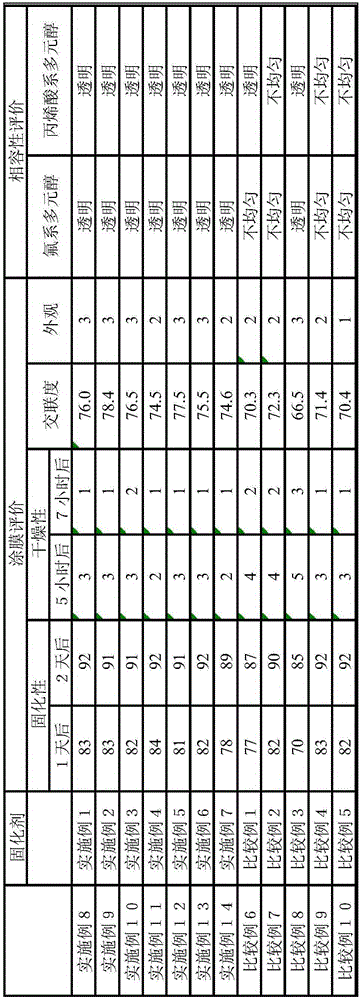

[0112] Synthesis was carried out in the same manner as in Example 1, except that the composition and reaction conditions of the charged raw materials were changed to those shown in Table 1. Table 1 shows the composition and reaction conditions of these input raw materials and the physical properties of this polyisocyanate composition.

[0113] Table 2 shows the compatibility evaluation results of the polyisocyanate compositions obtained in Examples 1 to 7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com