Technical method of microwave pyrolysis treatment of municipal sludge

A municipal sludge and pyrolysis technology, which is applied in the direction of pyrolysis treatment of sludge and vaporization of by-products, etc., can solve the problems of low gas production rate, low oil production quality, and no guarantee of biosafety performance of sludge residues. Achieve the effect of reducing the harm of environmental pollution and responding quickly and efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

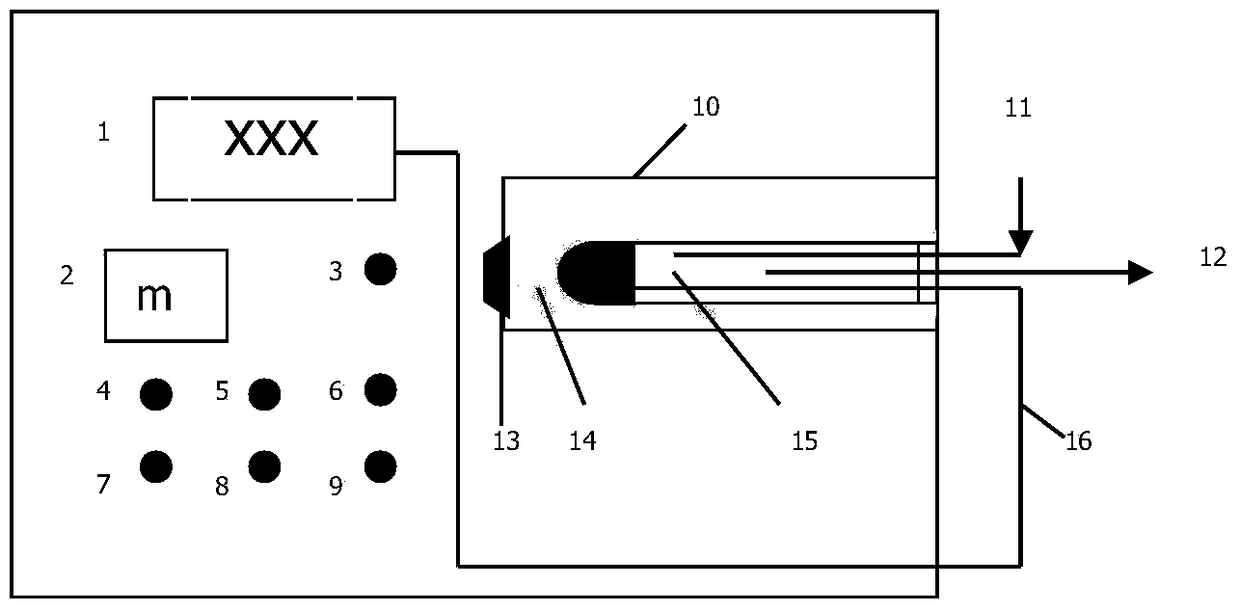

[0046] Example 1 Microwave pyrolysis treatment of municipal sludge device

[0047] according to figure 1 , the (single-mode microwave oven) device includes, 1-temperature display, 2-ammeter, 3-power adjustment knob, 4-operation switch, 5-stop switch, 6-timing switch, 7-lighting switch, 8-emergency stop Switch, 9-microwave switch, 10-single-mode microwave oven cavity, 11-high-purity nitrogen delivery part, 12-product collection part, 13-microwave transmitter, 14-insulation cotton, 15-quartz reactor, 16-thermocouple.

[0048] Wherein, the front portion of 1-single-mode microwave oven cavity is provided with 13-microwave launcher, 15-quartz reactor is placed inside 1-single-mode microwave oven cavity, 16-thermocouple is arranged at the front portion of 15-quartz reactor, and 13-corresponding to the microwave transmitter, 11-high-purity nitrogen delivery part and 12-product collection part are separately placed inside the quartz reactor. Components 3-9 control the reaction in th...

Embodiment 2

[0051] Embodiment 2 The technical method of microwave pyrolysis treatment municipal sludge device, comprising:

[0052] The experimental device (single-mode microwave oven) of the present invention described in the examples and the method for in-situ pyrolysis and fixing of metals to microwaves are used.

[0053] The first step: Dry the raw sludge of the sewage treatment plant until the quality does not change;

[0054] The second step: Grind the sludge into small particles, add pyrolysis catalyst and microwave absorber, stir and mix;

[0055] The third step: put the sludge into the microwave pyrolysis device, and then pass in nitrogen to pyrolyze;

[0056] The fourth step: cooling after reaction to collect energy gas and treated sludge.

[0057] Experimental conditions: before microwave pyrolysis, high-purity nitrogen gas (99.9%) was introduced for 20 minutes at a flow rate of 100 mL / min. After the start of microwave heating, adjust the nitrogen flow to 30-40mL / min. The p...

Embodiment 3

[0060] Embodiment 3 effect evaluation

[0061] Wherein, dry sludge: water according to the following ratio, unit: g / ml After being processed according to the device of embodiment 1 and the method of embodiment 2, the result of producing energy gas is as follows:

[0062]

[0063]

[0064] By adopting the control of the preferred pyrolysis temperature, pyrolysis time, microwave absorber and pyrolysis catalyst etc. in the present invention, the above corresponding energy gas results can be obtained, and the sludge can be effectively treated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com