A fall prevention device for c-shaped steel guide rail

A technology of C-shaped steel and guide rails, which is applied to the accessories of scaffolding, scaffolding supported by building structures, buildings, etc., can solve the problem of inconvenient height adjustment of guide rails, improve anti-fall response performance, facilitate installation and maintenance, and prevent guide rails from falling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] , clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them. Based on the implementation manners in the present invention, all other implementation manners obtained by persons of ordinary skill in the art without making creative efforts belong to the scope of protection of the present invention.

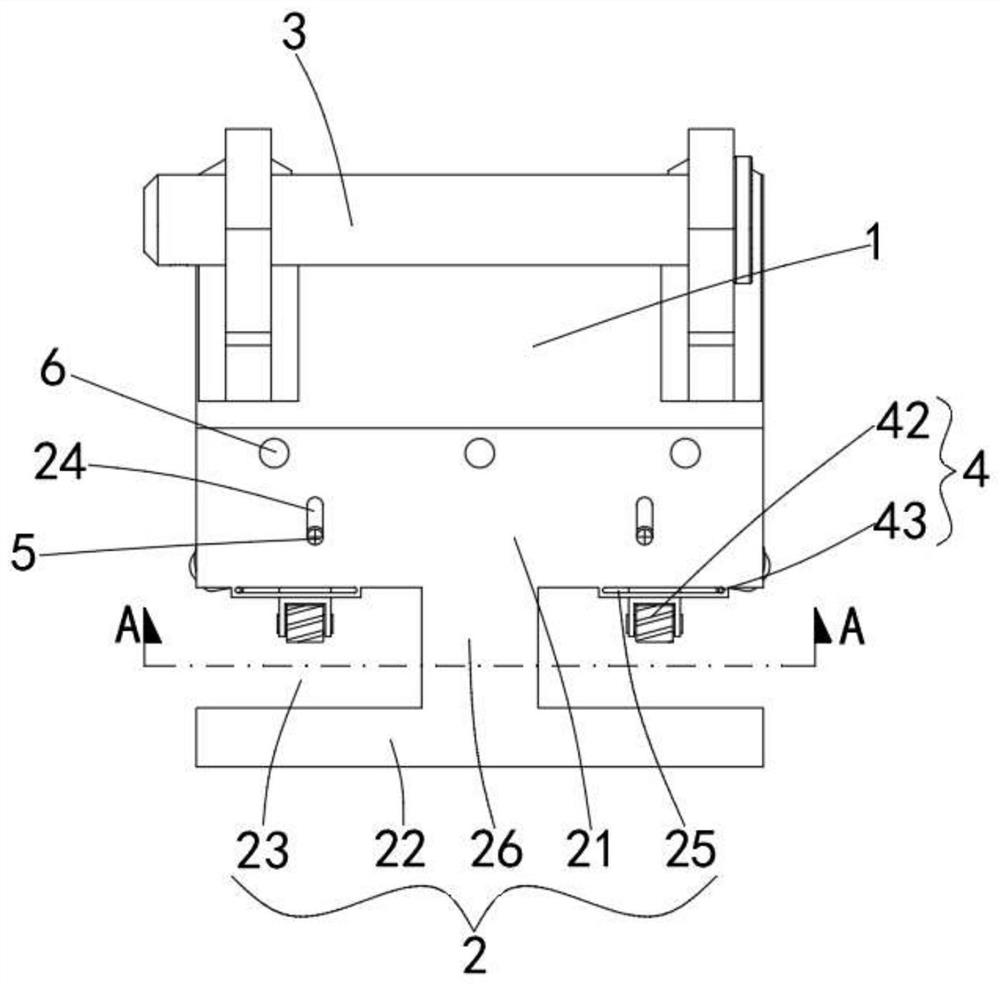

[0029] Such as figure 1 shown, combined with Figure 4 with Image 6 , a kind of anti-dropping device for C-shaped steel guide rail of the present invention comprises a wall seat mechanism and a guide rail 7, the wall seat mechanism is fixedly installed on a wall, and the guide rail 7 has a C-shaped opening 71, and the opening 71 is two The side has a flange 72 , and also includes a main body 1 , a movable body 2 , a hinge seat 3 , a locking part 4 , a rotating shaft 5 and a positioning assembly 6 . .

[0030] Wherein, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com