Production method for feed-grade monocalcium phosphate

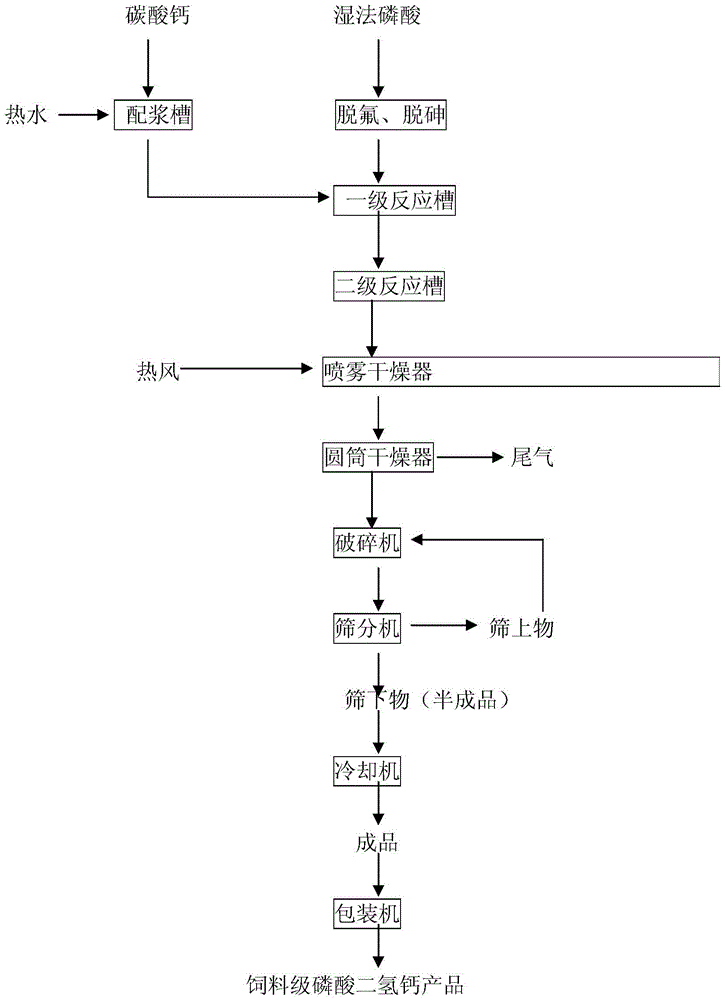

A technology of calcium dihydrogen phosphate and a production method, applied in the field of phosphate, can solve the problems of unstable product quality, large land occupation for device construction, and high equipment investment, and achieve the effects of shortened production time, reduced production site area, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] First the quality score (in P 2 o 5 40% to 50% of raw material phosphoric acid is defluorinated and dearsenized according to the conventional method, and it is used after meeting the process requirements; the raw material calcium carbonate with a mass fraction of more than 98% is mixed with water in the slurry tank to make mass Fraction is 50% calcium powder slurry, standby;

[0031] Send the phosphoric acid and calcium powder slurry that meets the process requirements into the primary reaction tank for neutralization reaction. The temperature is controlled at 40°C to 60°C. Most of the phosphoric acid and calcium powder react to become calcium dihydrogen phosphate, and the slurry is stirred evenly. The slurry is pumped out and sent to the secondary reaction tank; the slurry continues to undergo neutralization reaction in the secondary reaction tank, and the temperature is controlled at 75 ° C ~ 95 ° C, so that most of the phosphoric acid and calcium powder react to bec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com