Method for obliquely inserting and mounting high-voltage bushing once through intelligent protractor

A high-voltage bushing and energy technology, which is applied in transportation and packaging, load hanging components, cranes, etc., can solve the problems of large cost investment, time-consuming, and laborious, and achieve the effect of improving work efficiency and widening the operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

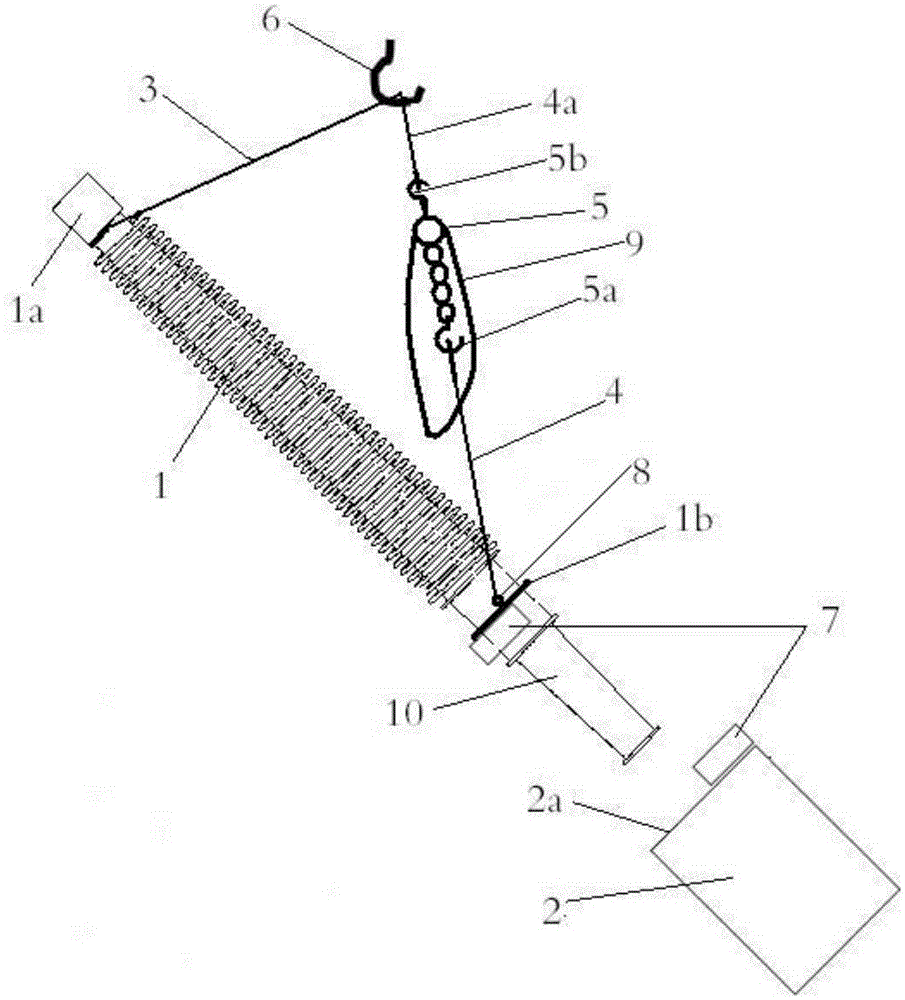

[0015] Such as figure 1 As shown, the method of the present invention to complete the oblique insertion and installation of high-voltage bushings at one time by means of an intelligent protractor is to adjust the angle of the suspended high-voltage bushing 1, and then obliquely insert the tail end into the inclined high-voltage equipment 2 interface. The specific operation method is as follows :

[0016] 1) Install the "Smart Toolbox" software on the smartphone;

[0017] 2) Open the "Smart Toolbox" software on the smartphone, and click the "Angle" option;

[0018] 3) Put the long side of the smart phone 7 with the protractor displayed on the mobile phone window parallel to the inclined flange surface 2a of the interface of the high-voltage equipment 2, and record the value of the inclination angle of the flange surface;

[0019] 4) The high-voltage bushing is hoisted in the air with a lifting device combined with the main sling 3, upper auxiliary sling 4a, lower auxiliary sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com