Automatic oil feeder for assembly line and hook head assembly line containing same

An assembly line and oiler technology, which is applied in the direction of transportation and packaging, cleaning devices, conveyor objects, etc., can solve the problems of unusable triangular plates, high maintenance costs, broken shaft wheels, etc., so as to avoid affecting the normal operation of the workshop and reduce Maintenance cost, effect of extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

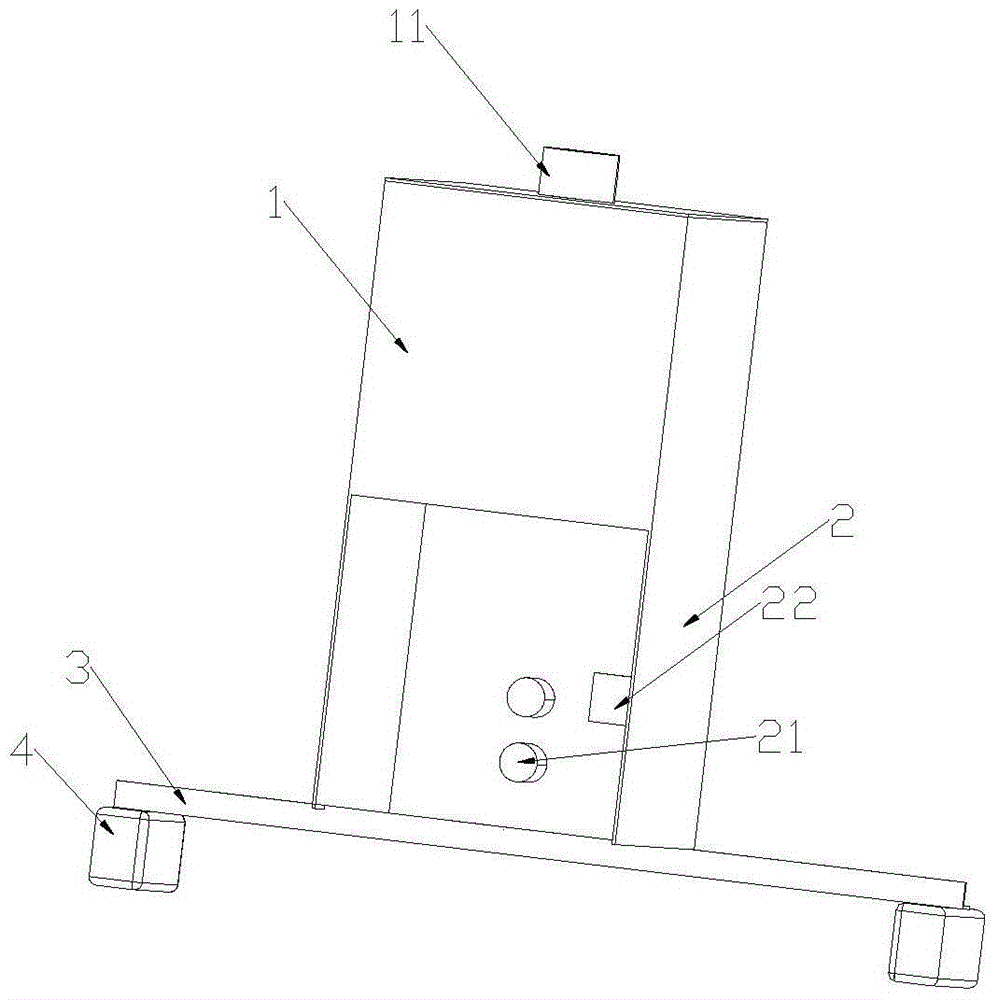

[0019] Such as figure 1 As shown, the present invention provides a kind of assembly line automatic oiler, comprises bracket 2 and fuel tank 1, and fuel tank 1 is fixed on the bracket 2, and the top of fuel tank 1 is provided with oil filling port 11, and the bottom of fuel tank 1 is provided with oil outlet pipeline, A control switch 21 for opening and closing the oil outlet pipeline in good time is installed on the support 2 . The oil tank is only used to store lubricating grease, and its material can be stainless steel, 45# steel plate or other materials. In order to better observe the oil quantity in the oil tank 1, a transparent observation window can be set on the oil tank body and set Scaled accordingly for refilling when required. The material of the bracket can be angle steel or channel steel, both of which are made of Q235, ordinary carbon structural steel, the yield limit is 226MPa, and the tensile strength is about 375-460MPa; due to the moderate carbon content, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com