Preheating box for leather embossing machine

A technology of embossing machine and preheating box, which is applied in the field of leather embossing machines, can solve the problems of insufficient preheating temperature, insufficient heating effect, and complexity of quartz heating tubes, and achieve the effect of reducing power and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

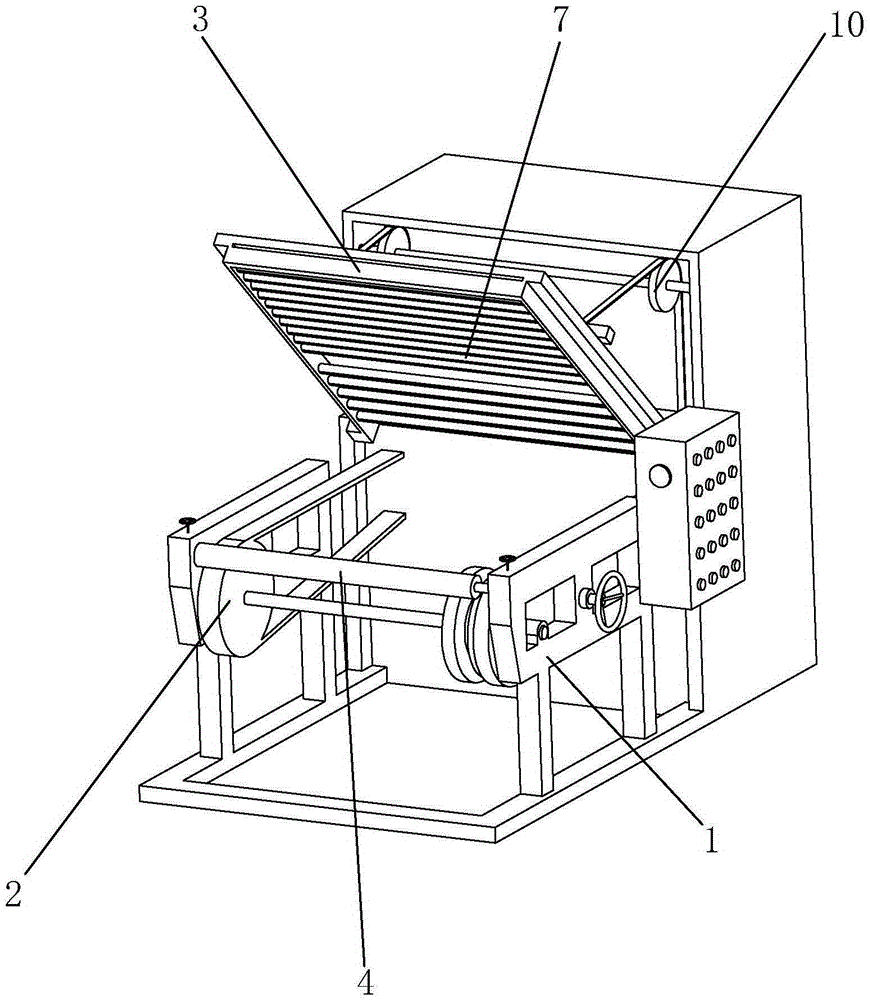

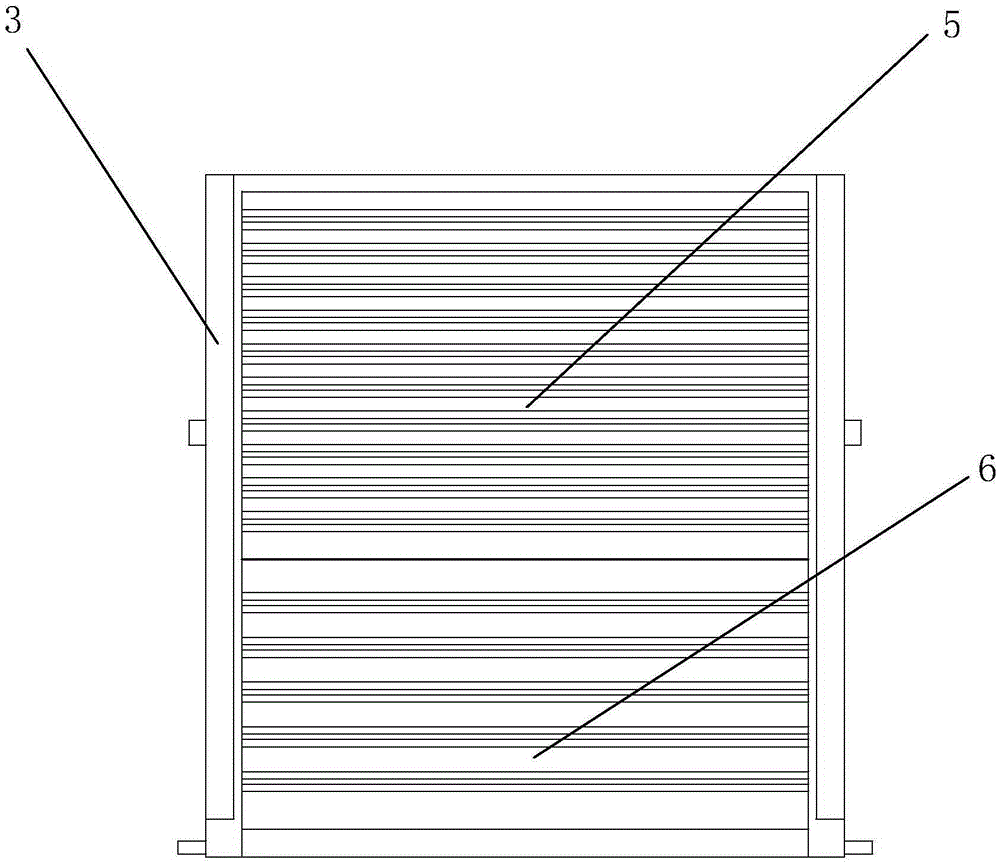

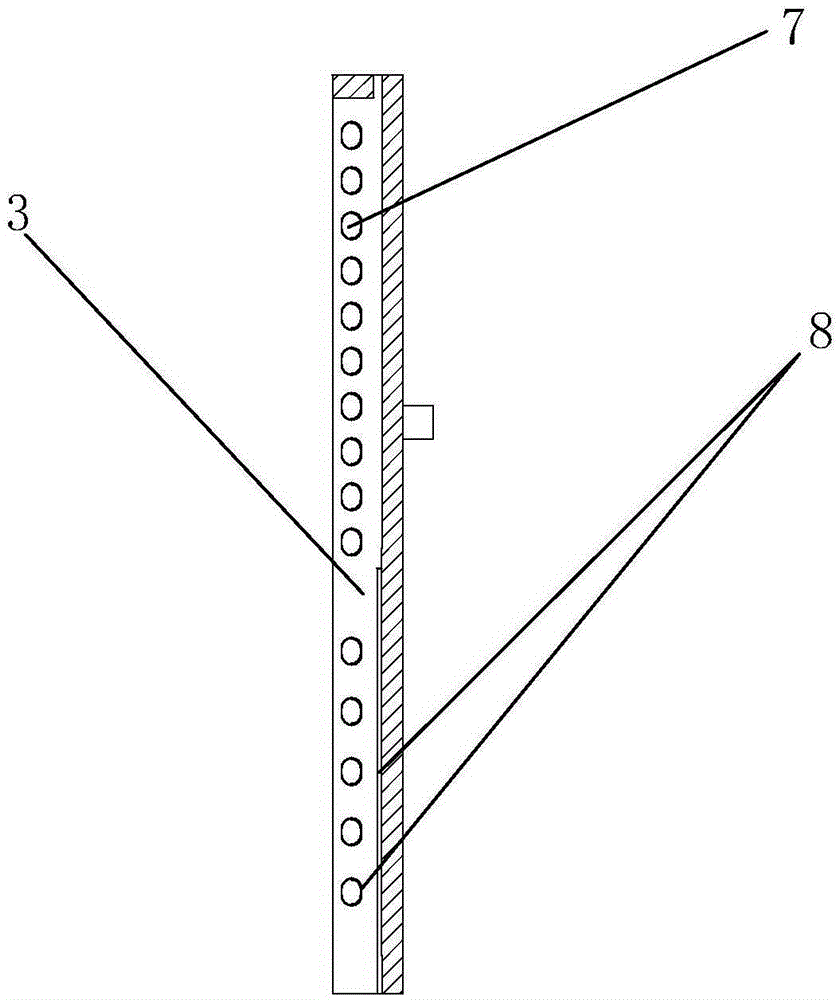

[0031] Example 1: Reference figure 1 , figure 2 , image 3 , A preheating box of a leather embossing machine. The preheating box is installed at the next station of the unwinding section of the unwinding leather. At the previous station of the embossing box, the preheating box serves to preheat the leather The preheating box in this solution includes a frame 1, and a heating cover 3 is hinged on one end of the frame 1 close to the embossing box. At the same time, a lifting group 10 is provided to flip the heating cover 3, and the lifting group 10 A motor can be used to drive the reel to rotate. The front end of the rope on the reel is connected to the other end of the upper surface of the heating mantle 3 away from the hinge. The heating mantle 3 can be opened and closed by the lifting group 10 to facilitate the heating of the heating mantle 3 Operation and distribution of leather in rack 1.

[0032] Conveyor belt set 2 is set on both sides of frame 1. Conveyor belt set 2 is a p...

Embodiment 2

[0034] Example 2: The difference from Example 1 is that Figure 4 As shown, there is also a steam pre-drying rack at the front end of the rack 1, and the structure of the steam pre-drying rack is basically the same as the existing foundation, and the pre-drying rack 9 has reached the preheating function here, preventing The temperature in the rack 1 increases too fast during heating. In addition, the purpose of using the steam pre-drying rack 9 is to perform steam humidity treatment on the leather. The steam liquefied water vapor serves the purpose of absorbing heat and cooling, reducing the heating speed and preventing the leather from heating up too fast and causing damage to the leather.

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com