Method and device for separating oil-bearing metal powder

A technology of metal powder and centrifugal separation, which is applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of low metal recovery rate and environmental pollution, and achieve high degree of automation, easy operation of equipment and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

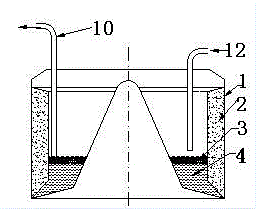

[0020] A method for separating oil-containing metal powder, adding water to the oil-containing metal powder, centrifuging the oil-containing metal powder added with water, under the action of centrifugal force, the water squeezes out the oil, and the water occupies the position of the oil to replace the oil, A water-containing metal powder layer, a water layer and an oil layer are formed. The oil-containing metal powder is an oil-containing ground metal powder. The oil-containing metal powder is pretreated, and oil is added to the oil-containing metal powder to make an oil slurry 9, and the slurry is centrifuged to separate a part of the oil. The oil added to the oil-containing metal powder is the same oil as the oil-containing metal powder itself.

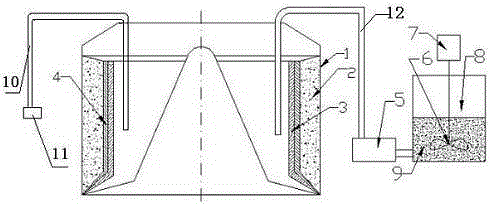

[0021] A device for separating oily metal powder, comprising a centrifuge, a feed pipe 12, a slurry pump 5, a stirring paddle 6, a slurry tank 8 and a speed regulating motor 7, one end of the feed pipe 12 extends into the centrif...

Embodiment 2

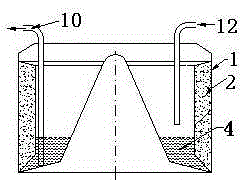

[0024] A method for separating oil-containing metal powder, adding water to the oil-containing metal powder to make a slurry, centrifuging the oil-containing metal powder added with water, under the action of centrifugal force, the water squeezes out the oil, and the water occupies the position of the oil. The oil is displaced out to form a water-containing metal powder layer, a water layer and an oil layer. Oil-containing metal powder is a metal powder containing grinding.

[0025] A device for separating oily metal powder, comprising a centrifuge, a feed pipe 12, a slurry pump 5, a stirring paddle 6, a slurry tank 8 and a speed regulating motor 7, one end of the feed pipe 12 extends into the centrifuge, and The other end of the material pipe 12 is connected with the slurry pump 5, the slurry pump 5 is connected with the slurry mixing tank 8, the stirring paddle 6 is located in the slurry mixing tank 8, and the speed regulating motor 7 is connected at the top of the stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com