Synthesis method for zeolite-coated precious metal particles and application of zelite-coated precious metal particles in light paraffin isomerization

A precious metal and coating technology, used in molecular sieve catalysts, petroleum industry, refined hydrocarbon oil, etc., can solve the problems of inability to enter molecular sieve pores, bulk hydroxides, etc., to improve hydrogenation-dehydrogenation performance and improve metal dispersion. degree, the effect of reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

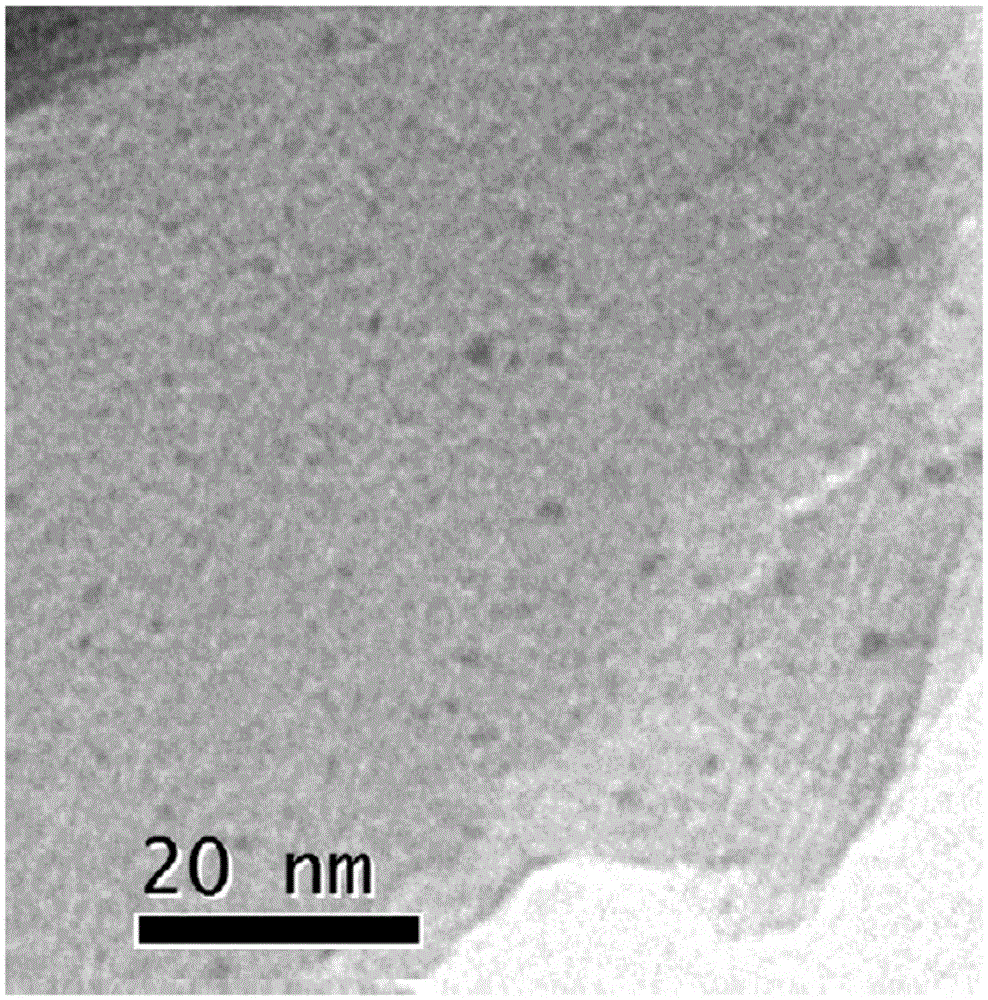

Image

Examples

Embodiment 1

[0030] The synthesis of the Beta zeolite of the BEA structure of embodiment 1 containing Pt or Pd

[0031] First, 0.75g NaOH and 2.3g TEAOH were mixed with 11.7g water and stirred vigorously to produce a clear solution. Then add 0.27g of NaAlO 2 into solution and vigorously stirred to produce clear Solution A.

[0032] 0.025g of [Pt(NH 3 ) 4 ]Cl 2 Solution B was obtained by adding 5 mL of water. Solutions A and B were mixed and stirred vigorously, then 5.0g of white carbon black was added and stirred vigorously for 2h to obtain a uniform gel. The molar ratio composition of the resulting gel is SiO 2 :0.014Al 2 o 3 :0.125Na 2 O: 0.060TEAOH: 30H 2 O.

[0033]The gel was dried at 333K in an air atmosphere to obtain a dried gel. Grind dry glue into powder for later use. Weigh 5g of dry glue fine powder, place it in the middle of a 150mL dry glue steam-assisted method (SAC) crystallization kettle, and then add 1.0mL of water to the bottom of it, and the dry glue does n...

Embodiment 2

[0044] The synthesis of the Beta zeolite molecular sieve of the BEA structure of embodiment 2 containing Pt-Pd

[0045] Take 6.00g silica, 19.88gTEAOH and 2.00gNH 4 F was mixed and stirred vigorously for 2h. Then take 0.01g and 0.1g of K 2 [PtCl 4 ] and K 2 [PdCl 4 ] was dissolved in 1.6mL deionized water to form a solution, added dropwise to the above system, and continued to stir for 2h to obtain a uniform gel. Then, the gel was dried at 333K in an air atmosphere to obtain a dry gel. Grind dry glue into powder for later use.

[0046] Weigh 2g of dry glue fine powder, place it in the middle of a SAC crystallization kettle with a volume of 150mL, and then add 1.5mL of water to the bottom, the dry glue does not directly contact with the bottom water of the kettle. At the crystallization temperature of 453K, the bottom of the kettle was converted into water vapor and crystallized for 6 hours. After the reaction, the obtained sample was washed, dried, and roasted at 823K f...

Embodiment 3

[0051] The synthesis of the mordenite of the MOR structure containing Pt or Pd in the channel of embodiment 3

[0052] 1.13g NaAlO 2 and 1.32 g of NaOH were dissolved in water to produce a clear solution. Then 20.1 g of bis(triethoxysilyl)methane (BTESM) was added. After mixing for 3 hours, then add 0.04g [Pt(NH 3 ) 4 ]Cl 2 solution 4mL. Stir for 1 hour, then vigorously stir for 30 minutes to form a viscous gel, and dry it at 333K to obtain dry gel. Move the above-mentioned dry glue into the middle of a 150mL crystallization kettle, and then add 10mL of water to the bottom, so that the dry glue does not directly contact with the bottom water of the kettle. After static crystallization at 453K for 3 days, it was taken out and cooled, filtered, washed, dried at 373K and roasted at 823K for 6 hours, then introduced hydrogen, and reduced at 623K for 3 hours to obtain Pt / MOR (catalyst F).

[0053] [Pt(NH 3 ) 4 ]Cl 2 Replaced with 0.05g [Pd(NH 3 ) 4 ](NO 3 ) 2 Soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com