SO2 and dust comprehensive treatment absorber

A comprehensive treatment and absorbent technology, applied in the direction of gas treatment, use of liquid separation agent, membrane technology, etc., can solve the problems of complex preparation methods, harsh reaction conditions, desulfurization agent can not achieve desulfurization and dust removal at the same time, to achieve simple preparation, The effect of low requirements on preparation conditions, good environmental benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] SO 2 , Preparation of dust absorbent

[0029] Choose 100m 3 Fermentation tank, add 0.3% corn steep liquor, 3% soybean flour, 0.1% soybean oil and add water to form a fermentation medium, add 5% Aspergillus species for fermentation; fermentation temperature is 30-35°C, stirring speed is 500rpm, fermentation After 30 hours, centrifuge to remove solid impurities to obtain fermentation broth.

[0030] Add 0.6% amphoteric surfactant (dodecyl ethoxy sulfobetaine) and 1% crushed grass clippings to the fermentation broth, and stir to obtain the protein ion membrane liquid.

[0031] Add NaOH and NaOH to the above protein ion membrane solution 2 CO 3 solution, so that the pH of the solution after mixing is 9, that is, SO 2 , Dust absorbent.

Embodiment 2

[0033] Desulfurization and dust removal process

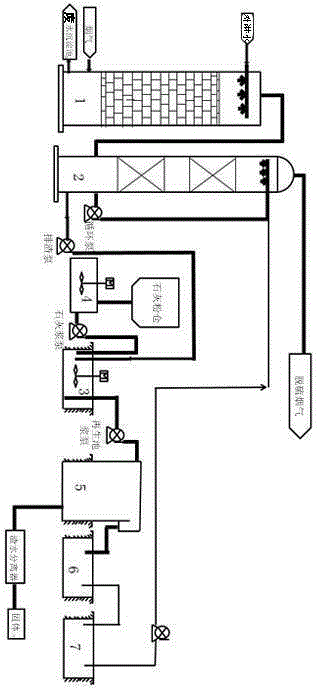

[0034] The treatment system includes a water film dedusting tower 1, a desulfurization tower 2, a regeneration tank 3, a lime slurry preparation tank 4, a sedimentation tank 5, a circulation tank 6, and an ion membrane liquid tank 7. The flue gas produced by two 35t boilers first enters the desulfurization tower 2 through the water film dedusting tower 1, and the SO prepared in the embodiment 1 in the desulfurization tower 2 , Dust absorbent to spray flue gas, absorb SO 2 Na 2 SO 3 The solution enters the regeneration tank 3, and the purified gas treated by the desulfurization tower is first monitored by an on-line monitoring instrument, and the flue gas that reaches the standard can be discharged into the atmosphere through the chimney, and the lime slurry prepared in the lime slurry preparation tank 4 is pumped into the regeneration tank 3 for regeneration. Stir and mix evenly in the pool 3 and pump it into the sedimentati...

Embodiment 3

[0038] SO 2 , Preparation of dust absorbent

[0039] Choose 100m 3 Fermentation tank, add 0.5% corn steep liquor, 5% soybean flour, 0.08% soybean oil and add water to form a fermentation medium, add 6% Aspergillus species for fermentation; fermentation temperature is 30-35°C, stirring speed is 500rpm, fermentation After 25 hours, centrifuge to remove solid impurities to obtain fermentation broth.

[0040] Add 0.8% amphoteric surfactant (dodecyl ethoxy sulfobetaine) and 1.2% crushed grass clippings to the fermentation broth, and stir to obtain protein ion membrane liquid.

[0041] Add Ca(OH) to the above protein ion membrane solution 2 with Na 2 CO 3 solution, so that the pH of the solution after mixing is 10, that is, SO 2 , Dust absorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com