Movable gas permeation membrane separating device

A gas permeable membrane and separation equipment technology, applied in the field of mobile gas permeable membrane separation equipment, can solve the problems of time-consuming and labor-intensive experimental conditions and engineering facilities, relatively high workplace requirements, and non-compliance with explosion-proof requirements. The effect of production coordination, reduction of on-site construction, and convenient mobile transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the scope of protection to be protected by the present invention will not be limited.

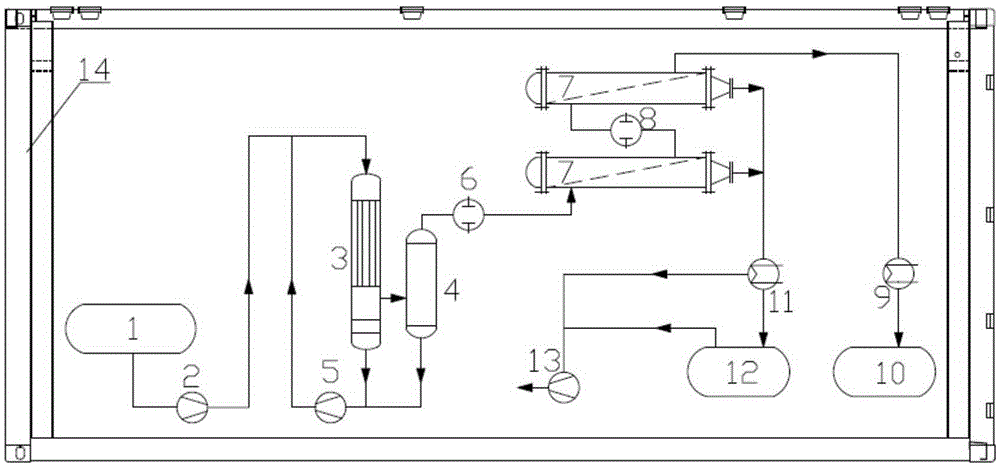

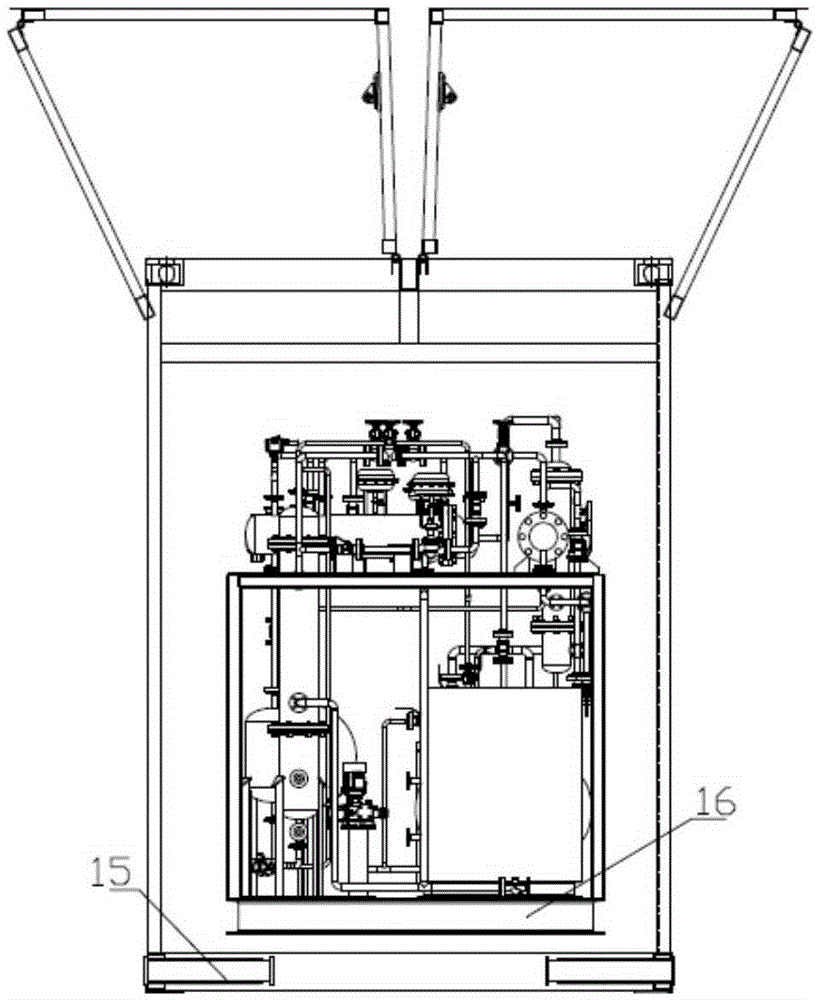

[0020] A mobile gas permeable membrane separation device, such as attached figure 2 As shown, it includes a flying-wing container skid 15 and a gas-permeable membrane separation skid 16 , and the gas-permeable membrane separation skid 16 is loaded inside the flying-wing container skid 15 . as attached figure 1 As shown, the gas permeable membrane separation skid 16 is mainly composed of a raw material tank 1, a raw material pump 2, an evaporator 3, a gas-liquid separator 4, a circulation pump 5, a superheater 6, a membrane module unit 7, a heat supplement 8, A product condenser 9, a product tank 10, a waste liquid condenser 11, a waste liquid tank 12, and a vacuum unit 13 are formed. The overall size of the mobile gas permeabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com