Carbonaceous heat source covered by flame-retardant material

A carbon heat source, flame retardant material technology, applied in the application, tobacco, smoker's products and other directions, can solve the problems of reducing production efficiency, inhalation, endangering health, etc., to reduce heat loss, sufficient sources, and prevent easy falling off. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

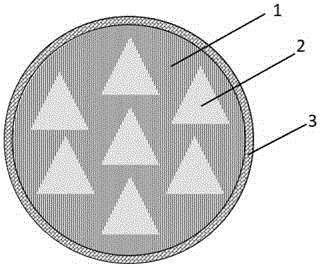

[0029] 1. Mix 75g of carbon powder, 10g of sodium alginate, 8g of calcium carbonate, 1g of iron oxide, 6g of potassium carbonate and 70g of water, and send them into a twin-screw extruder for extrusion. The twin-screw parameters are set as follows: temperature settings for each zone 30, and water is passed to keep the temperature fluctuation between ±5°C, the screw speed is set at 150 rpm, and after drying, a carbonaceous heat source rod 2 containing seven triangular longitudinal flow channels 1 is obtained;

[0030] 2. Mix 10g sodium alginate, 30g calcium carbonate, 5g magnesium hydroxide, 18g ceramic powder, 30g magnesium oxide whiskers, 2g iron oxide, 5g smoke foam, 0.5g corn oil and 30g water and then extrude with a single screw Out, make cylinder 3.

[0031] 3. Introduce the carbon heat source rod 2 into the die of the flame retardant material extruder in step 2, draw the material out from the other end of the die, and obtain a carbon heat source wrapped by the flame reta...

Embodiment 2

[0033] 1. Mix 80g of carbon powder, 7g of sodium alginate, 8g of calcium carbonate, 1g of iron oxide, 4g of potassium carbonate and 50g of water, and then transport them to a twin-screw extruder for extrusion molding. The twin-screw parameters are set as follows: temperature in each zone Set it to 30, pass water to keep the temperature fluctuation between ±5°C, set the screw speed to 150 rpm, and obtain a carbonaceous heat source rod 2 containing seven triangular longitudinal flow channels 1 after drying;

[0034] 2. Mix 50g sodium alginate, 25g calcium carbonate, 5g magnesium hydroxide, 10g ceramic powder, 10g magnesium oxide whiskers, 2g iron oxide, 5g smoke foam, 0.5g corn oil and 50g water and then extrude with a single screw Out, make cylinder 3.

[0035] 3. Introduce the carbon heat source rod 2 into the die of the flame retardant material extruder in step 2, draw the material out from the other end of the die, and obtain a carbon heat source wrapped by the flame retarda...

Embodiment 3

[0037] 1. Mix 85g of carbon powder, 6g of sodium alginate, 5g of calcium carbonate, 1g of iron oxide, 3g of potassium carbonate and 50g of water, and then transport them to a twin-screw extruder for extrusion molding. The twin-screw parameters are set as follows: temperature settings for each zone 30, and water is passed to keep the temperature fluctuation between ±5°C, the screw speed is set at 150 rpm, and after drying, a carbonaceous heat source rod 2 containing seven triangular longitudinal flow channels 1 is obtained;

[0038] 2. Mix 20g sodium alginate, 15g calcium carbonate, 25g magnesium hydroxide, 15g ceramic powder, 15g magnesium oxide whiskers, 5g iron oxide, 5g smoke foam, 0.5g corn oil and 50g water and then extrude with a single screw Out, make cylinder 3.

[0039] 3. Introduce the carbon heat source rod 2 into the die of the flame retardant material extruder in step 2, draw the material out from the other end of the die, and obtain a carbon heat source wrapped b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com