Time-interleaved assembly line ADC system and sequential operation method thereof

A technology of time interleaving and sequential operation, applied in analog-to-digital converters, electrical components, code conversion, etc., can solve problems such as high power consumption and consumption, improve sampling speed, reduce timing requirements, and save power consumption and area overhead Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

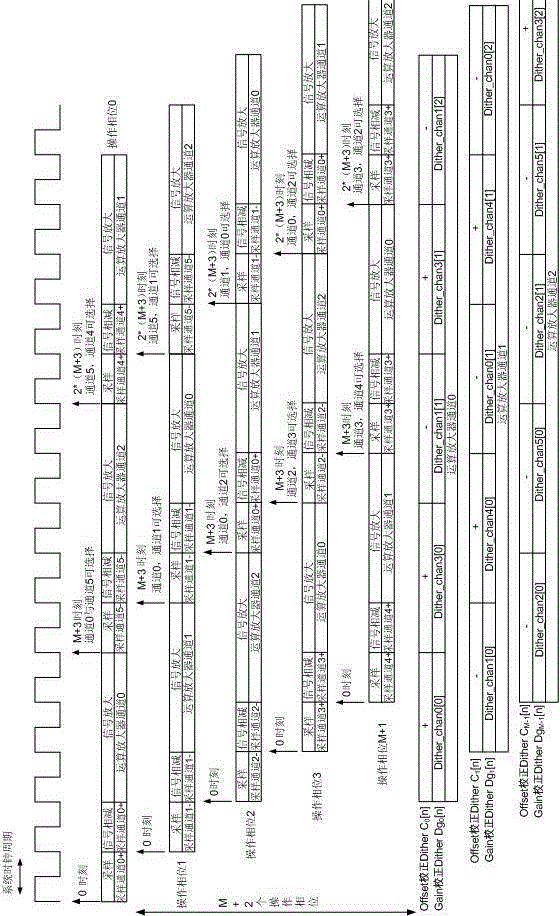

[0031] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

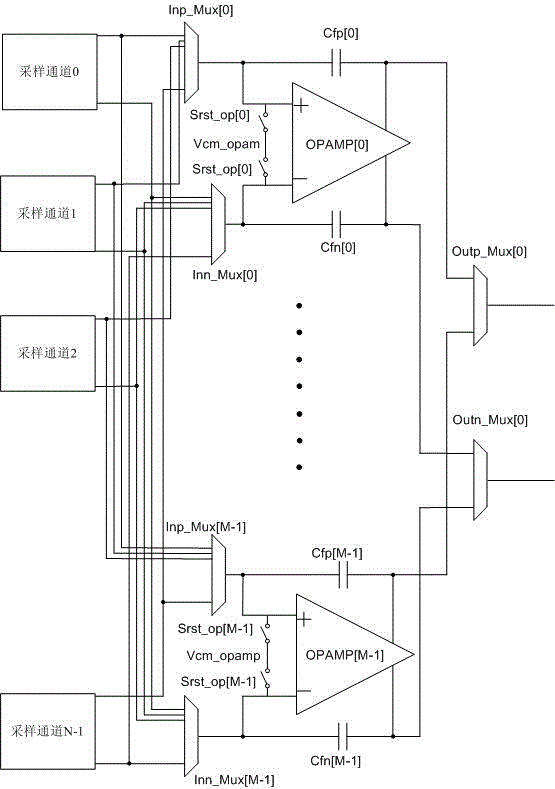

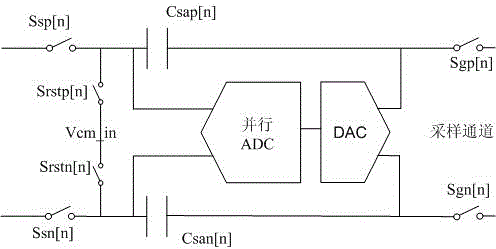

[0032] Such as figure 1As shown, a time-interleaved pipeline ADC system includes N sampling channels, M operational amplifier positive polarity channel input multiplexers, M operational amplifier negative polarity channel input multiplexers, M operational amplifiers and two output The multiple selector, the input of each sampling channel is connected to the input signal in parallel, and the output of each sampling channel is connected to the positive polarity channel input multiple selector of the operational amplifier and the negative polarity channel input multiple selector of the operational amplifier, and the positive polarity channel of the operational amplifier The output of the input multiple selector is connected to the positive inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com