Glass fibre cloth winding machine for galvanic pile

A glass cloth and winding machine technology, applied in the field of automation, can solve the problems of good and bad, low work efficiency, uneven winding quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

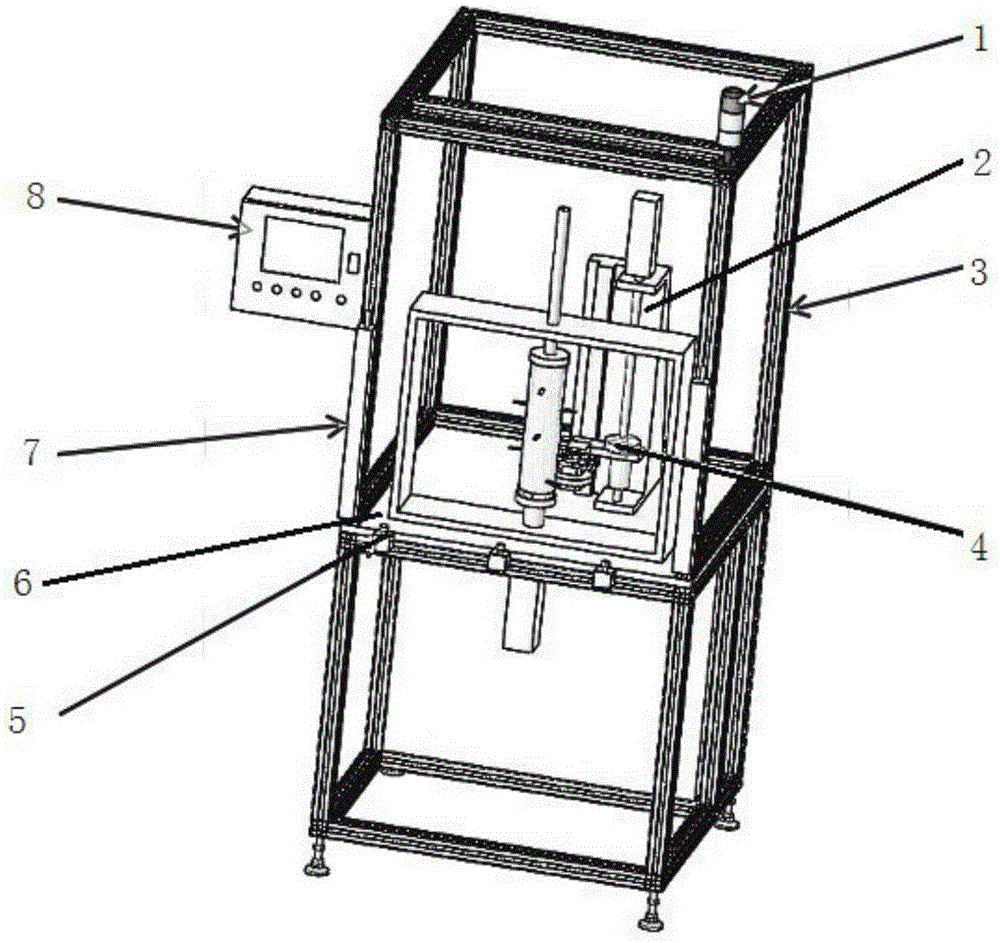

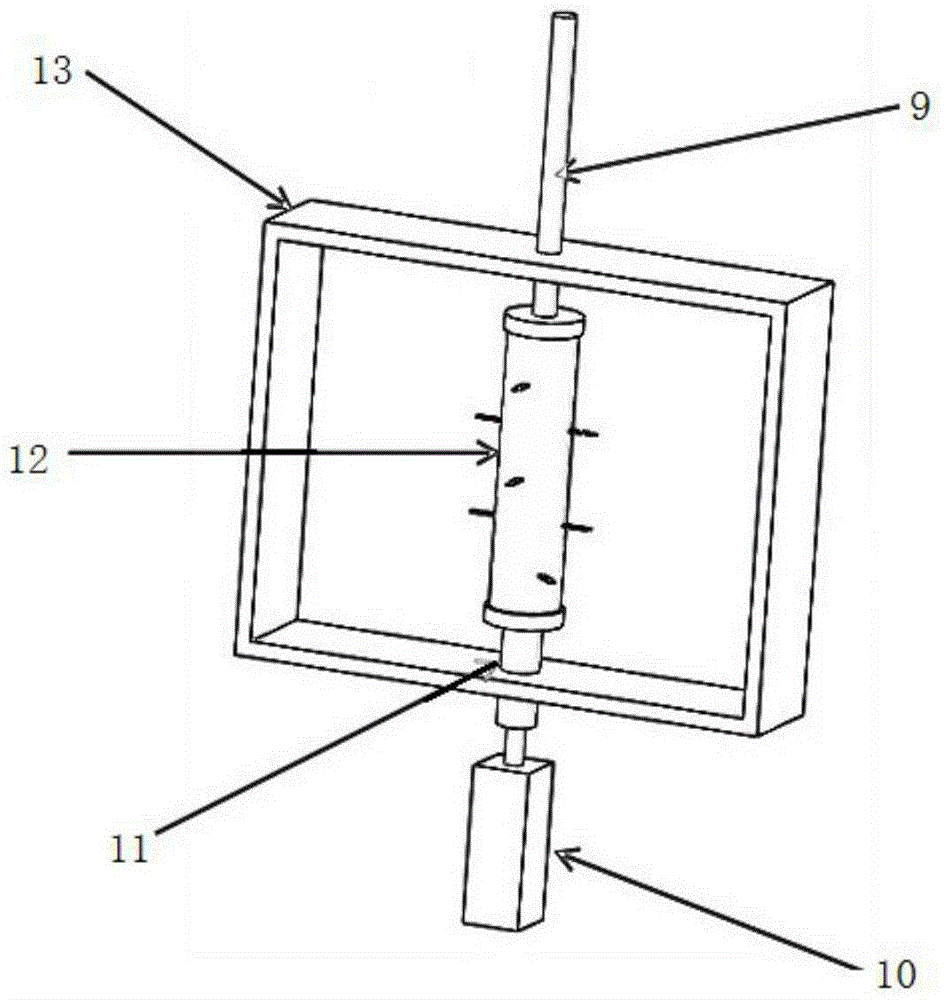

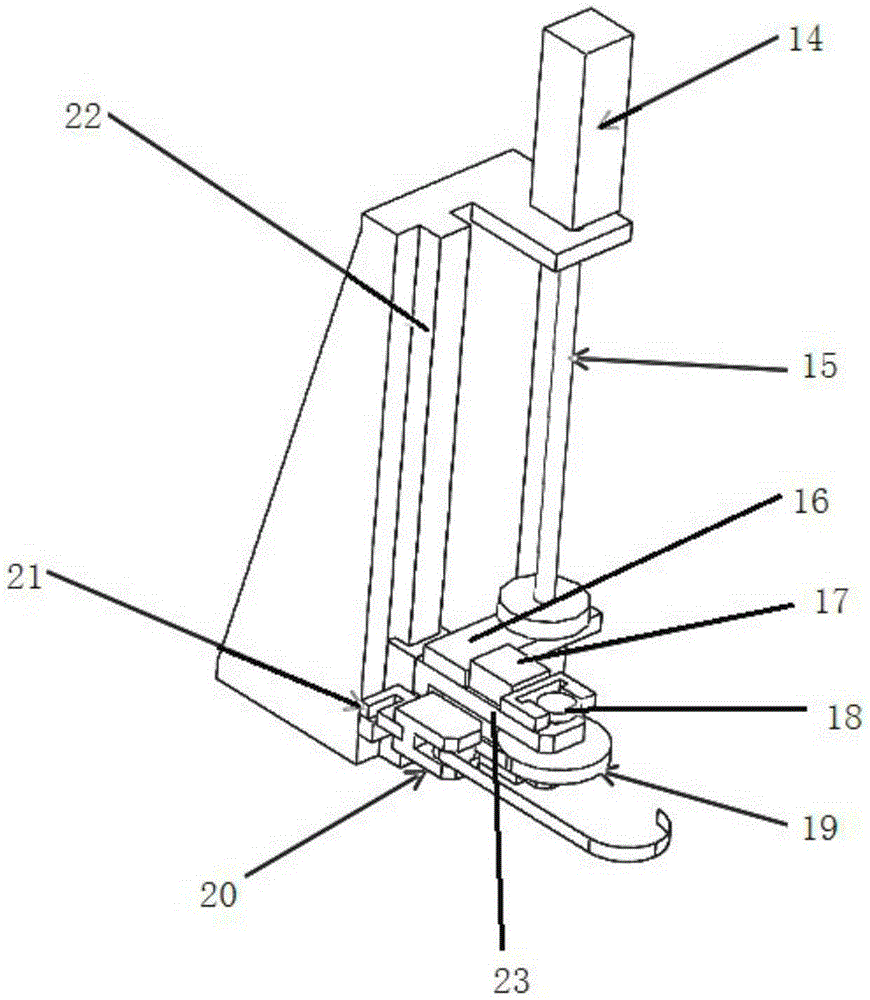

[0020] A cell stack glass cloth winding machine, comprising a frame 3, a workbench 6, a cell stack loading and unloading and rotating mechanism 4, a glass cloth rotation and lifting mechanism 2, the frame is divided into upper and lower parts by the workbench. The stack loading and unloading and rotating mechanism, glass cloth rotating and lifting mechanism are installed on the top surface of the workbench, a touch screen 8 is installed on the front column of the frame, and a pair of safety gratings 7 are symmetrically installed on the front two sides of the frame. Start and emergency stop button 5 are installed on the front side of the front workbench of frame, and tower light 1 is installed on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com