Mold and Stranding Table for Layer Stranded Optical Cable Twisted Head Outlet Cover

A layer-twisted optical cable technology, which is applied in the field of layer-twisted optical cable twist head exit cover molds and stranding tables, can solve the problems affecting the overall stability and instability of the cable tensile performance, and the exit of the twist head exit cover plate. Faster wear and tear of the casing tension and other issues, to avoid different degrees of wear, prolong the wear cycle, reduce the effect of friction cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

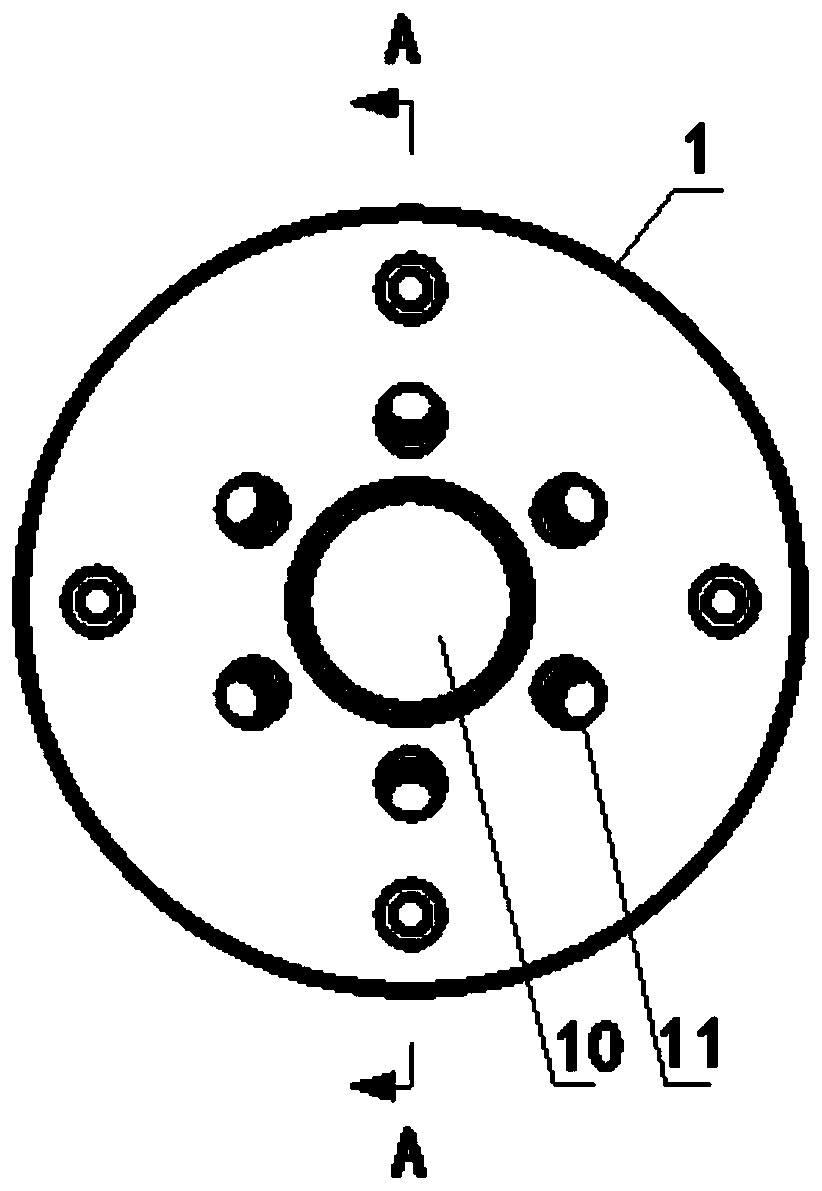

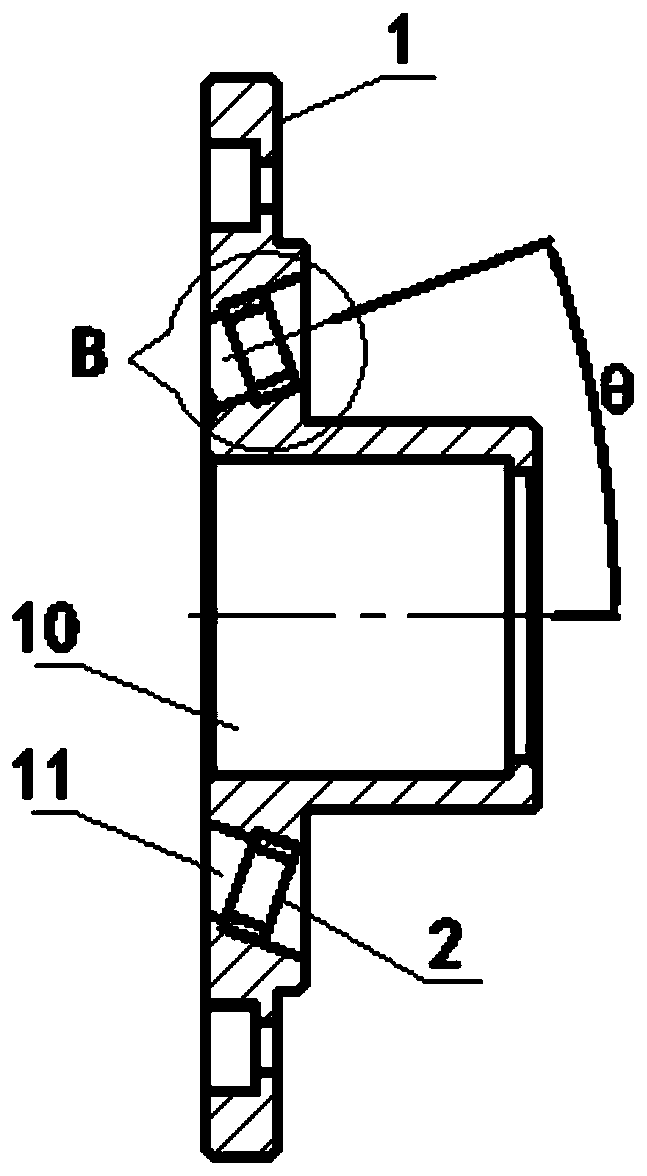

[0033] see figure 1 with figure 2 As shown, the embodiment of the present invention provides a layer-stranded optical cable twist head outlet cover plate mold, which includes a body 1, and the body 1 is provided with a reinforcement passing hole 10 and distributed around the reinforcement passing hole 10. A plurality of reaming holes 11, the number of reaming holes 11 can be set according to actual needs, see figure 1 As shown in , there are 6 reaming holes 11, and they are evenly distributed around the passage hole 10 of the reinforcement member, and the distance between each reaming hole 11 and the passage hole 10 of the reinforcement member is equal; The distance between the entrance end of the hole 11 and the passage hole 10 of the reinforcement is greater than the distance between the exit end and the passage hole 10 of the reinforcement, that is, the reamed hole 11 is an inclined hole, and the reamed hole 11 and The axial angle between the reinforcing member passage h...

Embodiment 2

[0038] see figure 1 with figure 2As shown, the embodiment of the present invention provides a layered type optical cable twist head outlet cover plate mold, which includes a body 1 and a plurality of low friction coefficient backing rings 2, and the body 1 is provided with reinforcement passing holes 10 and distributed in the The reinforcing member passes through a plurality of reaming holes 11 around the hole 10, and the distance between the inlet end of the reaming hole 11 and the reinforcing member passing hole 10 is greater than the distance between its outlet end and the reinforcing member passing hole 10 The low friction coefficient backing ring 2 is embedded in the reamed hole 11, and the reaming hole 11 and the low friction coefficient backing ring 2 located in the reaming hole 11 are arranged coaxially. The low friction coefficient backing ring 2 is arranged in the reamed hole 11, on the one hand, to allow the casing to not contact with the inner wall of the reamed ...

Embodiment 3

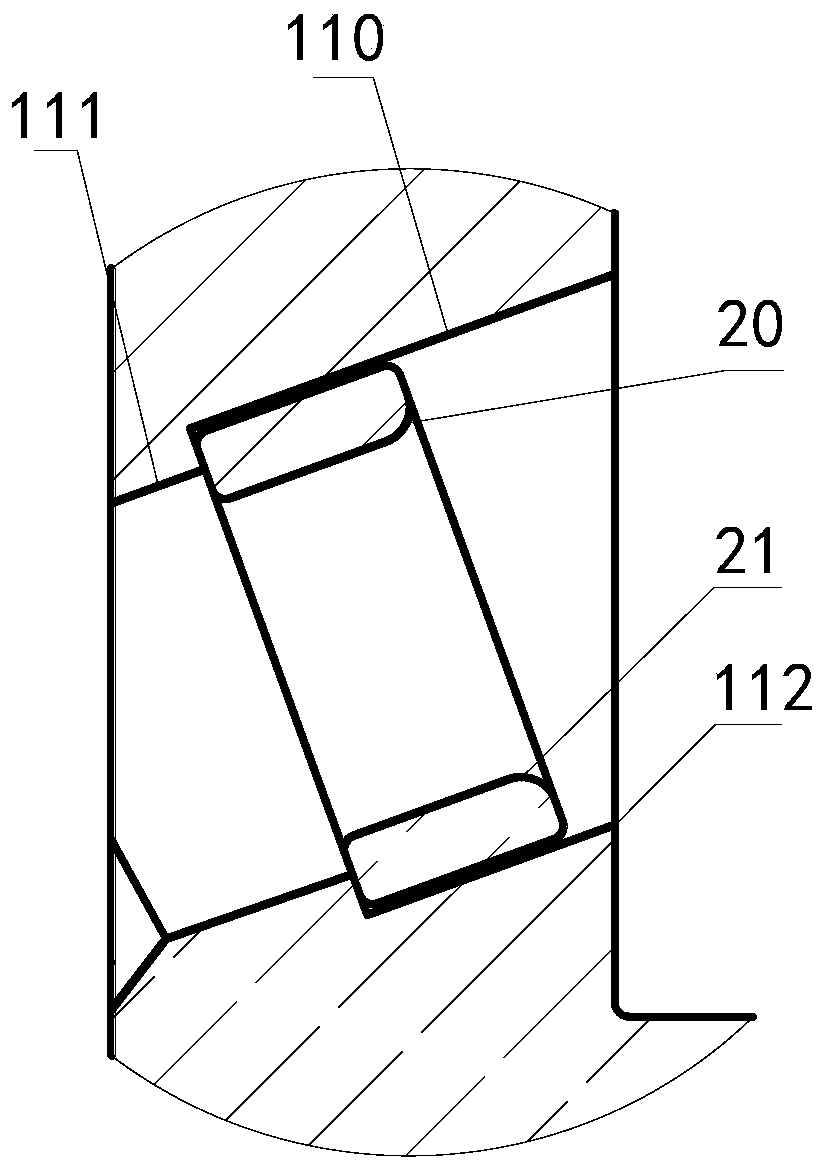

[0042] see picture figure 1 and figure 2 As shown, the embodiment of the present invention provides a layered type optical cable twist head outlet cover plate mold, which includes a body 1 and a plurality of low friction coefficient backing rings 2, and the body 1 is provided with reinforcement passing holes 10 and distributed in the The reinforcing member passes through a plurality of reaming holes 11 around the hole 10, and the distance between the inlet end of the reaming hole 11 and the reinforcing member passing hole 10 is greater than the distance between its outlet end and the reinforcing member passing hole 10 The low friction coefficient backing ring 2 is embedded in the reamed hole 11, and the reaming hole 11 and the low friction coefficient backing ring 2 located in the reaming hole 11 are arranged coaxially. see image 3 As shown, a chamfer 20 is provided on the inner wall of the low friction coefficient backing ring 2 near the inlet end of the reamed hole 11 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com