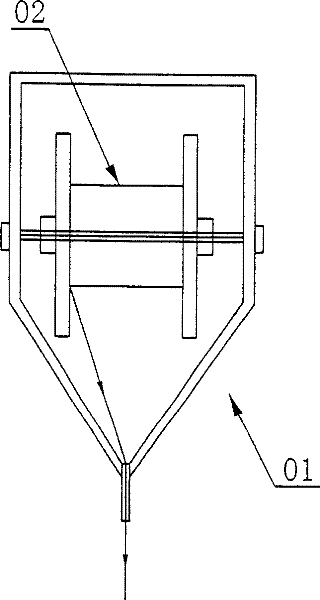

Untwisting pay-off device

A pay-off device and untwisting technology, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve problems affecting quality, unstable core wire tension, and easy torsion of shielded wires, etc., to achieve quality improvement, stability and reliability tension control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

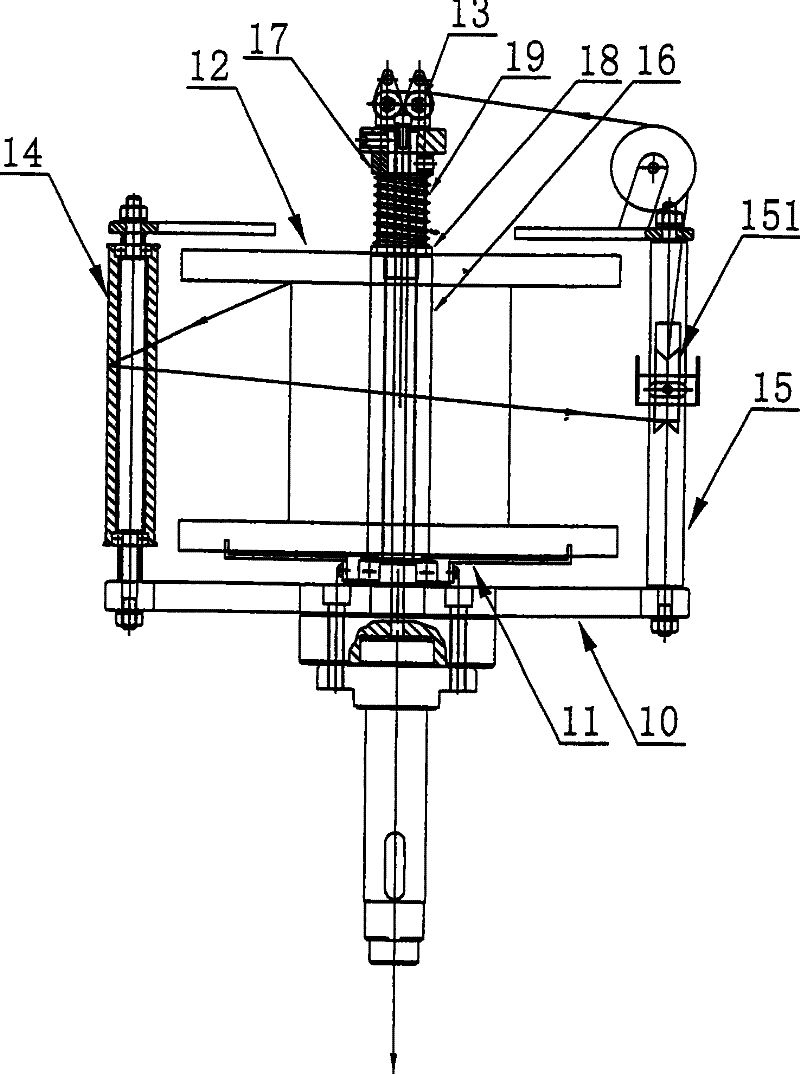

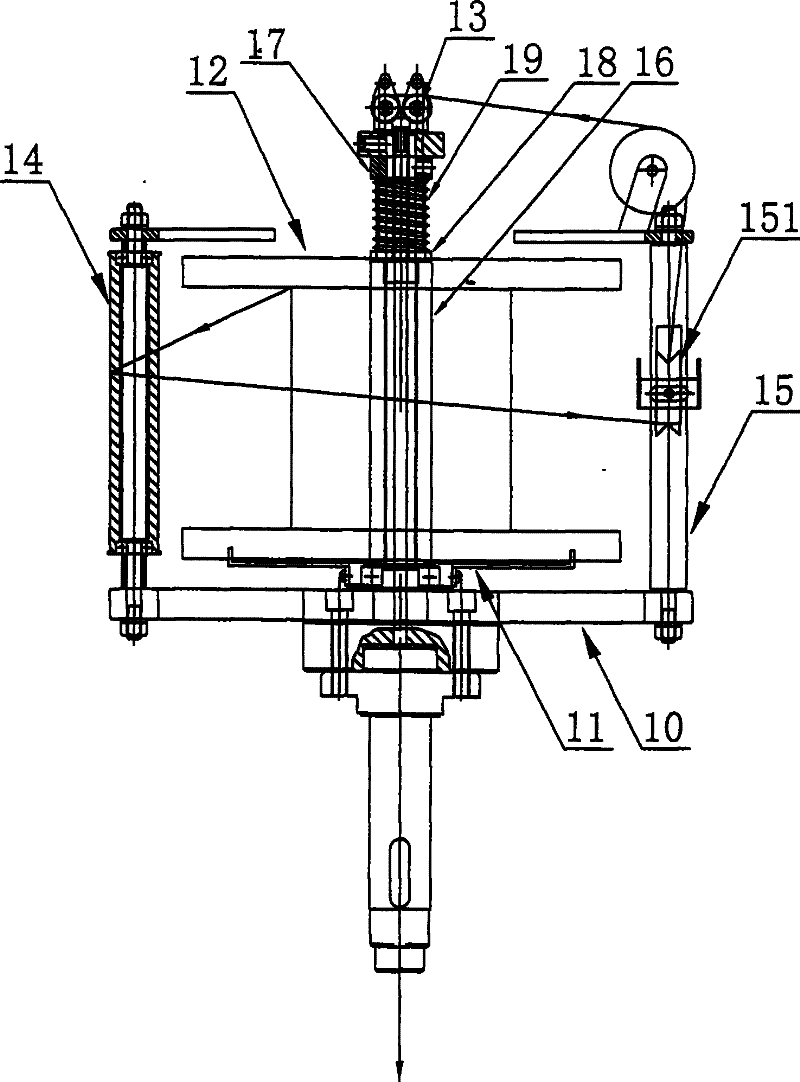

[0013] See attached figure 2 , the present invention includes a frame 10, on which a dial 11 for fixing a pay-off wheel 12 is installed, and the dial 11 is installed in the middle of the frame 10, connected to a motor through a transmission mechanism, and controlled by the motor The disc 11 rotates, so that the pay-off wheel 12 rotates together. When the take-up wheel rotates and pulls the core wire, the pay-off wheel 12 can continue to pay off.

[0014] A hollow shaft 16 is installed coaxially with the dial 11 on the frame of the present invention, the hollow shaft 16 is hollow, and the top is movably fixed with two parallel wire passing wheels 13, and the gap between the two parallel wire passing wheels 13 can be Adjusts to accommodate the passage of core wires of different thicknesses.

[0015] A column 15 is also fixed on the frame 10, and a cable pulley 151 is movably fixed on the column 15. The core wire is sent to the cable pulley 151 after passing around the core wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com