Hydraulic system of hydraulic self-moving type movable transformer train

A technology for shifting trains and hydraulic systems, applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., can solve the problems of pallet truck interference, pallet truck movement instability, and poor coordination of movements, etc., to improve flexibility , improve simultaneity, reduce the effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in terms of specific embodiments in conjunction with the accompanying drawings.

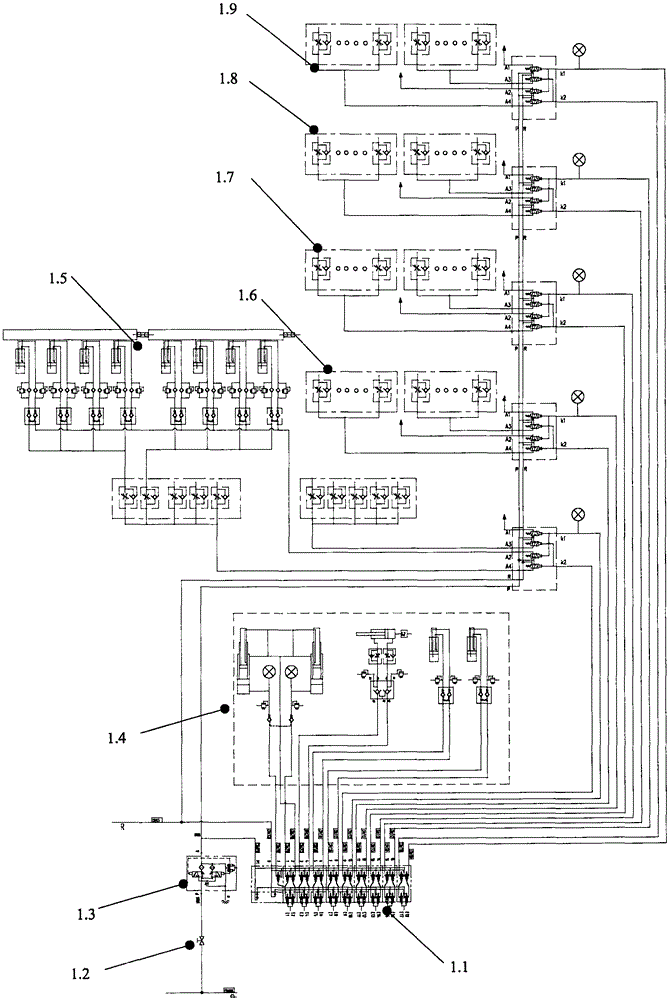

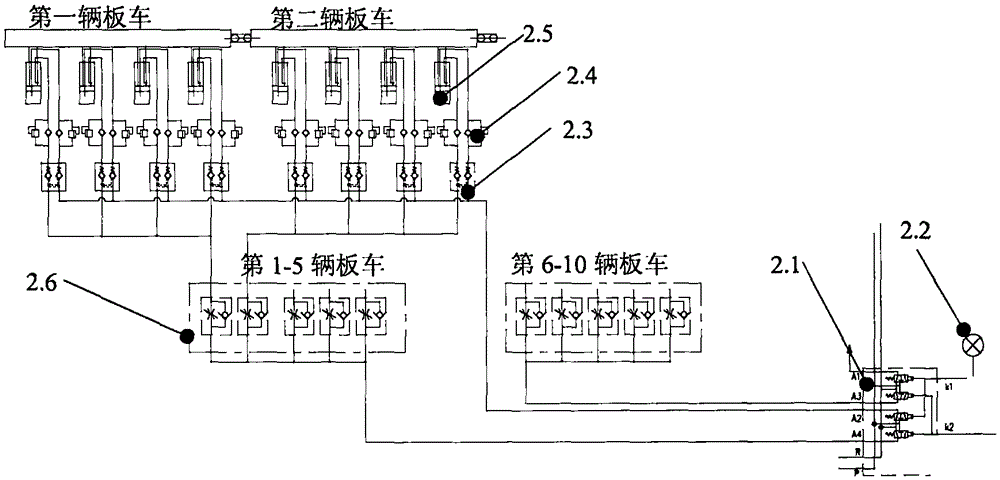

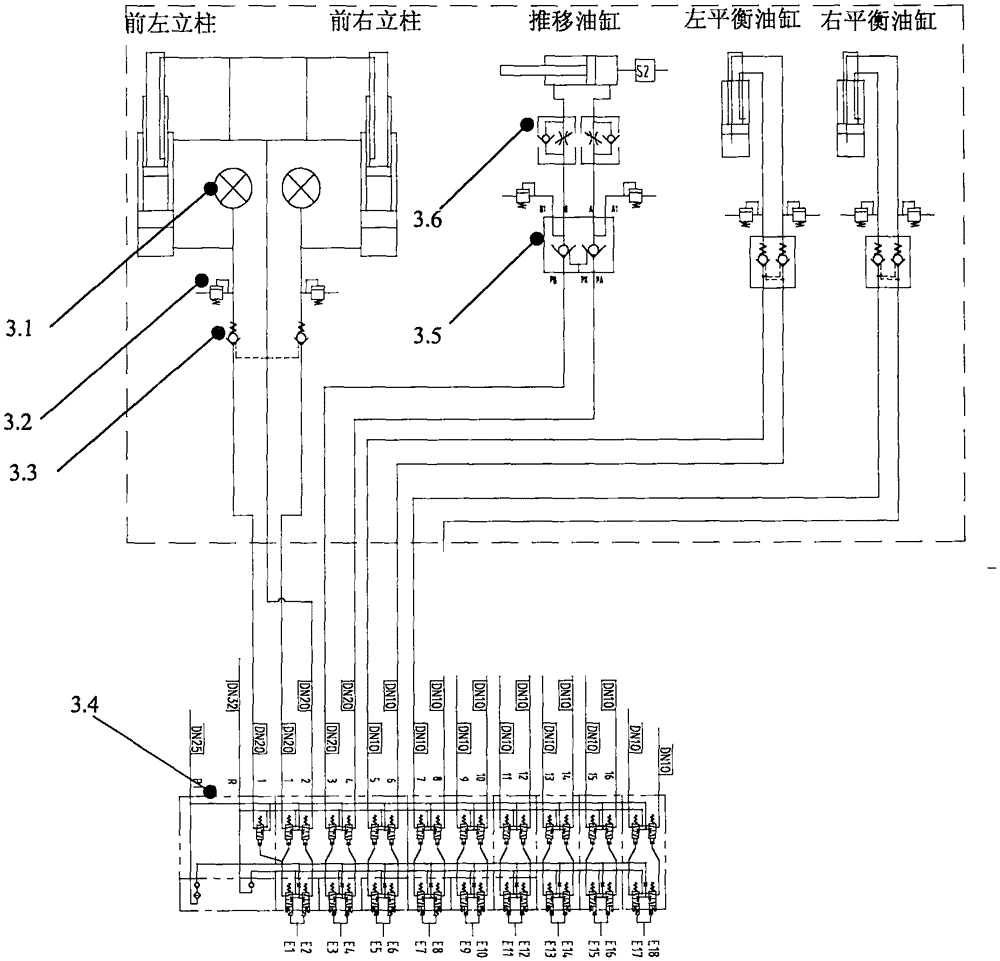

[0025] See attached figure 1 , which describes the schematic diagram of the overall system of the hydraulic self-moving shift train that controls the hydraulic control reversing valve through the hydraulic control port to realize partition control in the present invention; the self-moving shift train follows the layout of the hydraulic control reversing valve for partition control , by controlling the control port of the hydraulic control reversing valve separately to realize the group lifting and lowering action of the shifting train; the high-pressure pipeline P pipe is the main inlet pipeline, which is respectively connected with the main inlet P port of the hydraulic control reversing valve of each zone ;The low-pressure pipeline R pipe is the main liquid return pipe, which is respectively connected with the main liquid re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com