A kind of galvanized dual-phase steel for 500mpa class car and production method

A dual-phase steel and car technology, applied in the hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problems that are not suitable for the production of high-quality galvanized dual-phase steel, and achieve uniform color and no defects, Good plating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

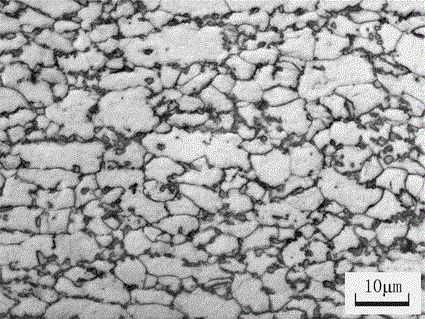

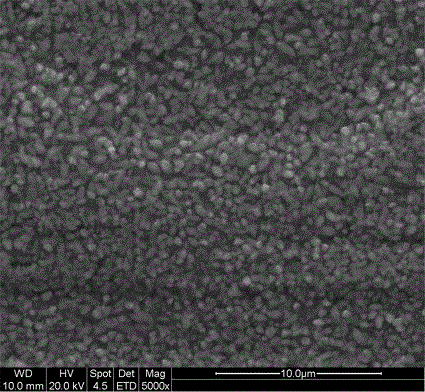

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below:

[0040] Table 1 is a list of component values of each embodiment and comparative example of the present invention;

[0041] Table 2 is a value list of main process parameters of each embodiment and comparative example of the present invention;

[0042] Table 3 is a list of performance detection conditions of various embodiments and comparative examples of the present invention.

[0043] Each embodiment of the present invention is produced according to the following steps:

[0044] 1) After smelting, refining and continuous casting into a slab according to the set composition, the slab is heated, and the heating temperature is 1200~1260℃;

[0045] 2) Perform finishing rolling, and control the final rolling temperature at 880~920℃;

[0046] 3) Coiling: the coiling temperature is controlled at 570~610℃;

[0047] 4) Cold rolling after pickling: the pickling temperature is controlled at 70~90℃, the acid value of the acid pool is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com