Welding strip annealing apparatus

A technology of annealing device and welding strip, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of low productivity, inconvenience, large labor force, etc., and achieve the effect of reasonable structure and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

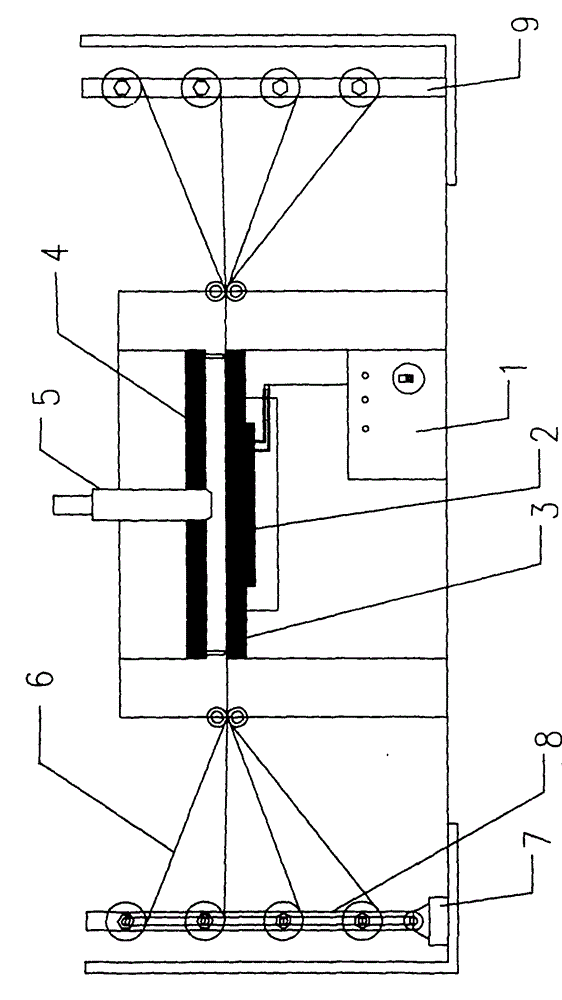

[0008] The implementation and working principle are further described in detail below in conjunction with the accompanying drawings:

[0009] See attached figure 1 : the upper steel plate 4 and the lower steel plate 3 form an annealing furnace cavity, the upper steel plate 4 is equipped with a protective gas inlet 5 (can be provided with multiple air inlets 5), and the high frequency coil 2 is close to the lower steel plate 3 to generate eddy current to make the lower steel plate 3 heat generation, a plurality of winding wheels equipped with welding ribbon 6 are sequentially installed on the secondary rotating wheel roller of the pay-off frame 9, and the welding ribbon 6 passes through the annealing furnace cavity and is wound on the take-up wheel of the take-up frame 8 in turn Turn on the power supply and turn on the high-frequency controller 1 to control the eddy current generated by the high-frequency coil 2 to the lower steel plate 3 to heat the steel plate, and the shield...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com