Method for producing aviation fuel from fatty alcohols

A technology for aviation fuel and fatty alcohol, which is applied in the preparation of biological raw materials, liquid hydrocarbon mixtures, and petroleum industry, etc., can solve the problem of high price of high-quality fatty alcohol, and achieve the effects of high product yield, good economy, and environmentally friendly and clean process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Use n-decyl alcohol (n-C 10 h 21 OH) as raw material for processing.

[0023] (1), using Al-MCF as step (1) catalytic dehydration catalyst, the loading amount of catalyst is 500g. The reaction pressure is 0.1MPa, the reaction temperature is 350°C, and the volume space velocity is 1h -1 .

[0024] The water in the product is separated, and the oil product is used as a raw material for step (2) hydroisomerization.

[0025] (2) Use Pt / ZSM-22 as the hydroisomerization catalyst in step (2), the loading amount of the catalyst is 500g, and the mass ratio of Pt to ZSM-22 is 0.005:1. The reaction pressure is 4.0MPa, the reaction temperature is 300°C, and the volume ratio of hydrogen to normal olefins is 200:1Nm 3 / m 3 , the volumetric space velocity is 0.1h -1 .

[0026] The product was collected, weighed and analyzed for product properties, the results are shown in Table 1.

Embodiment 2

[0028] Use n-decyl alcohol (n-C 10 h 21 OH) as raw material for processing.

[0029] (1), use ZSM-5 as step (1) catalytic dehydration catalyst, and the loading amount of catalyst is 500g. The reaction pressure is 0.1MPa, the reaction temperature is 250°C, and the volume space velocity is 1h -1 .

[0030] The water in the product is separated, and the oil product is used as a raw material for step (2) hydroisomerization.

[0031] (2) Use Pt / ZSM-22 as the hydroisomerization catalyst in step (2), the loading amount of the catalyst is 500g, and the mass ratio of Pt to ZSM-22 is 0.005:1. The reaction pressure is 4.0MPa, the reaction temperature is 300°C, and the volume ratio of hydrogen to normal olefins is 200:1Nm 3 / m 3 , the volumetric space velocity is 0.1h -1 .

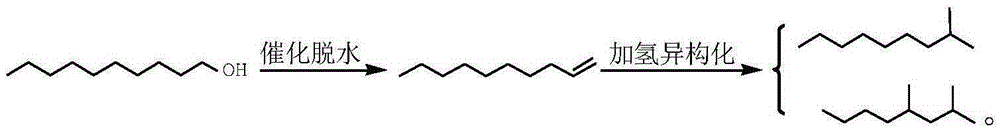

[0032] The reaction formula of embodiment 1 and 2 comprises as follows:

[0033]

Embodiment 3

[0035] Use C8-C16 mixed fatty alcohols as raw materials.

[0036] The catalytic dehydration and hydroisomerization conditions are the same as in Example 1.

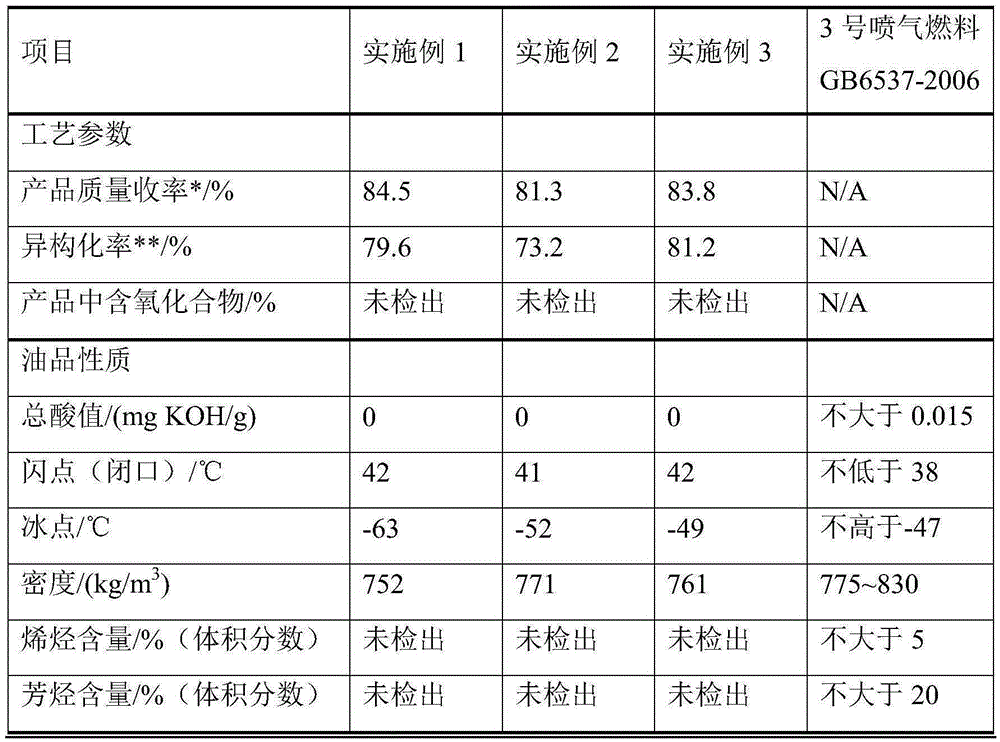

[0037] The properties of the obtained products are shown in Table 1.

[0038] Table 1

[0039]

[0040] *Based on the amount of n-decyl alcohol; **Isomerization rate=Isoparaffin mass / alkane mass*100%.

[0041] As can be seen from the results in Table 1, the jet fuel prepared by the method of the present invention with n-decyl alcohol as raw material can meet the requirements of No. 3 jet fuel except density, and can be used as the high-quality blending component of No. 3 jet fuel. The jet fuel prepared by using the mixed fatty alcohol of C8-C16 as a raw material by the method of the present invention meets the requirement of the No. 3 jet fuel, and can be directly used as the No. 3 jet fuel or as a high-quality blending component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com