Low-cost speed regulation, parking and anti-slip equipment

A technology of parking equipment and equipment, which is applied in the direction of railway car body parts, track brakes, transportation and packaging, etc., can solve the problems of unreasonable design, underutilization, high manufacturing cost, etc., and achieve little increase in cost, cost reduction, and saving Effective at a considerable cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

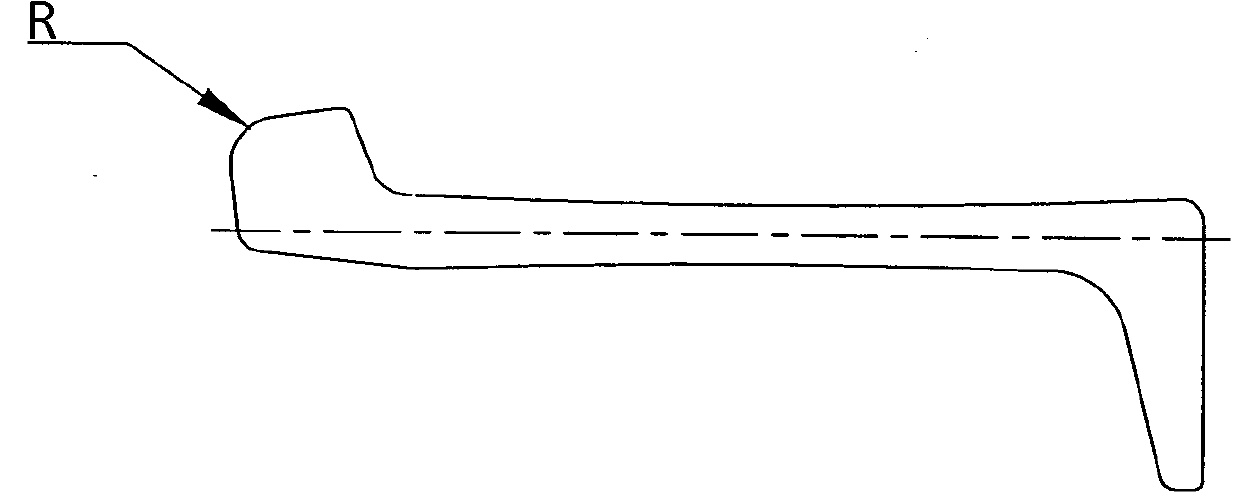

[0023] figure 1 What is shown is that a rail is divided into upper and lower parts from the waist part, the upper part and the lower part are separated by a certain distance in translation, and then the upper part and the lower part are connected by welding or riveting or other methods with steel plates, and the overrun part is removed.

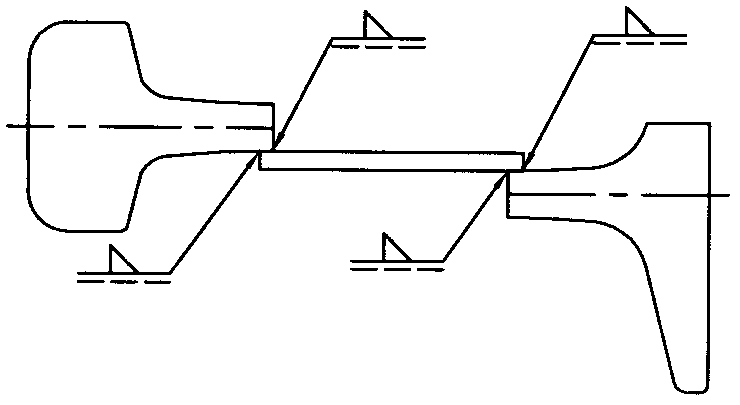

[0024] figure 2 What is shown is that a rail is divided into upper and lower parts from the waist part, and the upper part and the lower part are separated by a certain distance, and then the upper part and the lower part are connected by welding or riveting or other methods with steel plates. The overrun part is removed, and the head of the rail According to the need to deflect a certain angle downward, the angle size can be between 0-10 degrees or greater, preferably between 1.5-5 degrees.

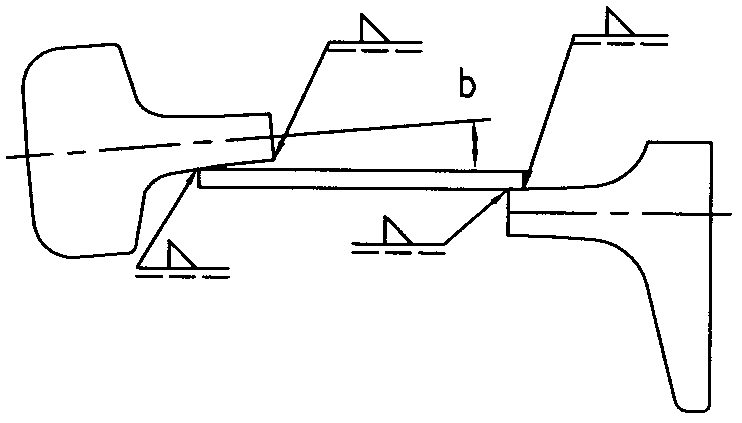

[0025] image 3 What is shown is that a rail is divided into upper and lower parts from the waist, and after the upper part and the lower part are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com