Quick pouring device of mold molten iron

A molten iron and mold technology, used in foundry equipment, manufacturing tools, and equipment for feeding molten metal into molds, etc., can solve problems such as casualties, molten iron waste, and impact on production and life, so as to ensure safe production and improve casting results. , The effect of high level of automation and intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

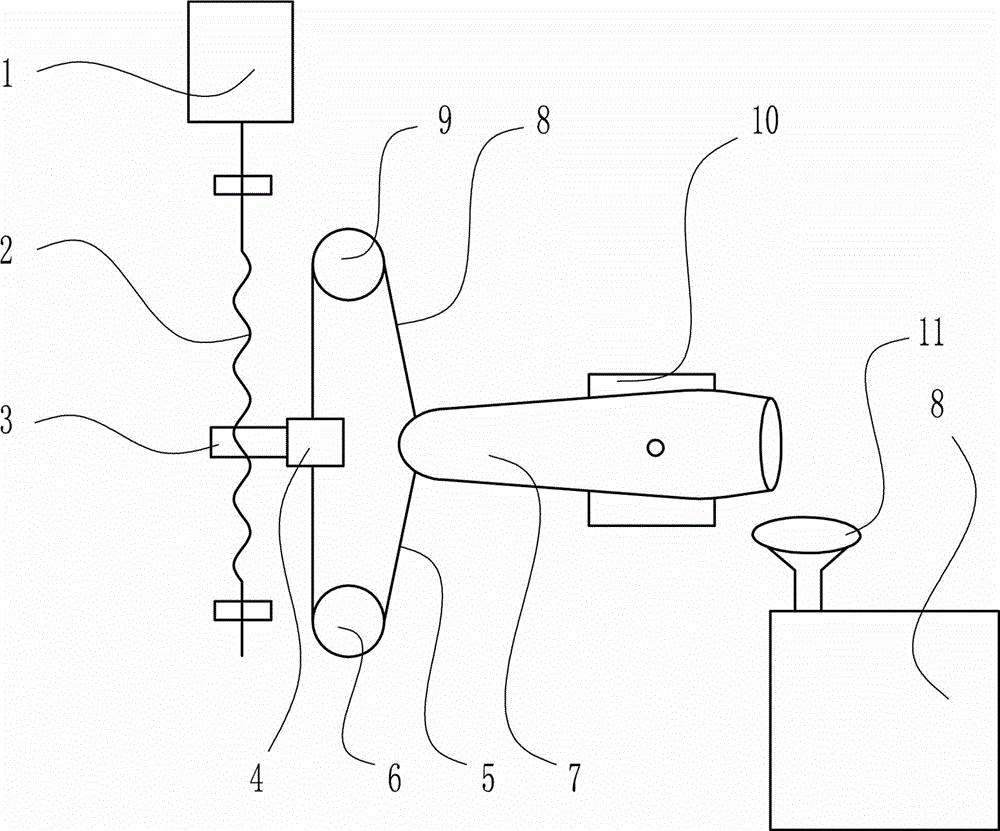

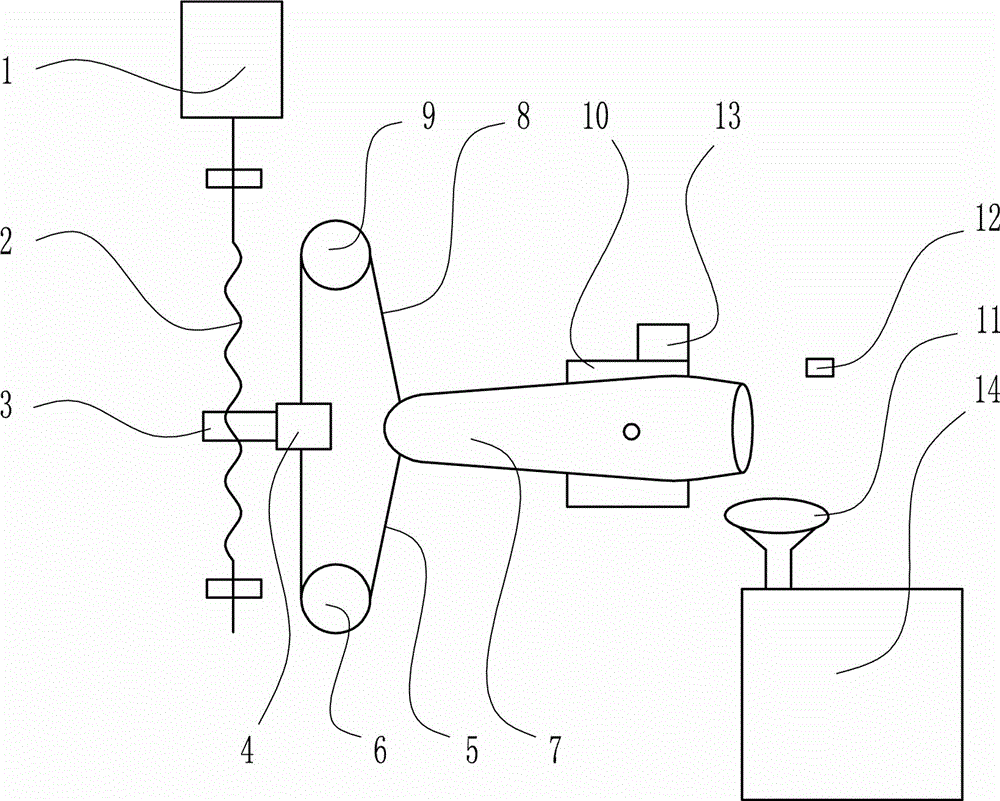

[0025] A mold molten iron rapid casting device, such as Figure 1-2 As shown, it includes motor I1, screw mandrel 2, nut 3, connecting block 4, pull-down rope 5, lower pulley 6, molten iron holding device 7, upper pulley 8, upper pulley 9, motor II10 and funnel 11;

[0026] The motor Ⅰ1 is connected with the screw rod 2 arranged below it, and a nut 3 is arranged on the screw rod 2, and the screw rod 2 cooperates with the nut 3; The bottom of block 4 is provided with pull-down rope 5 and lower pulley 6, and connecting piece 4 is connected with pull-down rope 5, and pull-down rope 5 passes through lower pulley 6, and pull-down rope 5 is movably connected with lower pulley 6;

[0027] A molten iron holding device 7 is arranged above the pull-down rope 5, and the pull-down rope 5 is connected with the molten iron holding device 7; Connected with the upper stay rope 8, the upper stay rope 8 passes through the upper pulley 9, the upper stay rope 8 is movably connected with the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com