Mold opening mechanism with mechanical advantage

A technology of mechanical gain and transmission mechanism, which is applied in the direction of handling casting equipment, metal processing equipment, casting equipment, etc., can solve the problems of unstable, accurate and reliable control of the opening and closing process, and unstable product quality, and achieves The effect of wide range of use, low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

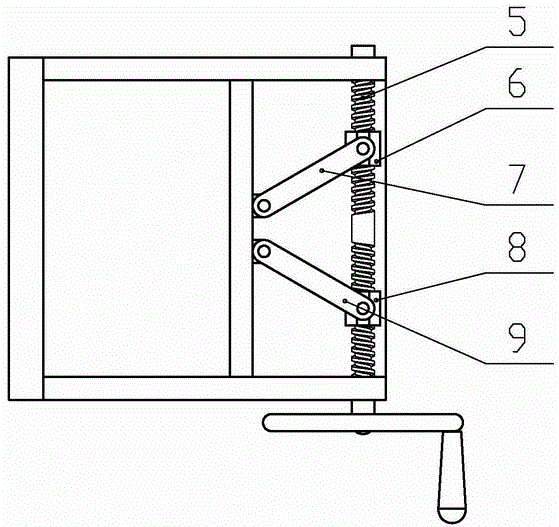

[0015] figure 1 , 2 Among them, the present invention includes a base 1 ; provided on the base 1 : a transmission mechanism, a movable mold mounting plate 3 connected with the transmission mechanism, and a static mold mounting plate 2 matched with the movable mold mounting plate 3 . The transmission mechanism includes a handwheel 4, a differential screw 5 connected with the handwheel 4, a nut A6 and a nut B8 matched with the differential screw, and two connecting rods 7 and two connecting rods B9. The differential screw 5 is mounted on the base 1 . The movable die mounting plate 3 is connected with the connecting rod A7 and the connecting rod B9 through the shaft; the nut A and the nut B are connected with the connecting rod A7 and the connecting rod B9 through the rotating shaft. The static mold mounting plate 2 is fixedly mounted on the base plate 1 . The thread of the nut A and the part that matches the differential screw 5 is left-handed, and the thread of the nut B and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com