Novel dynamic separation sieve

A separation screen and dynamic technology, applied in the direction of solid separation, filter screen, grid, etc., can solve the problems of destructive ground infrastructure, affecting screening efficiency, affecting normal operation, etc., to achieve stable operation of equipment and improve economic efficiency. Benefits, low vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

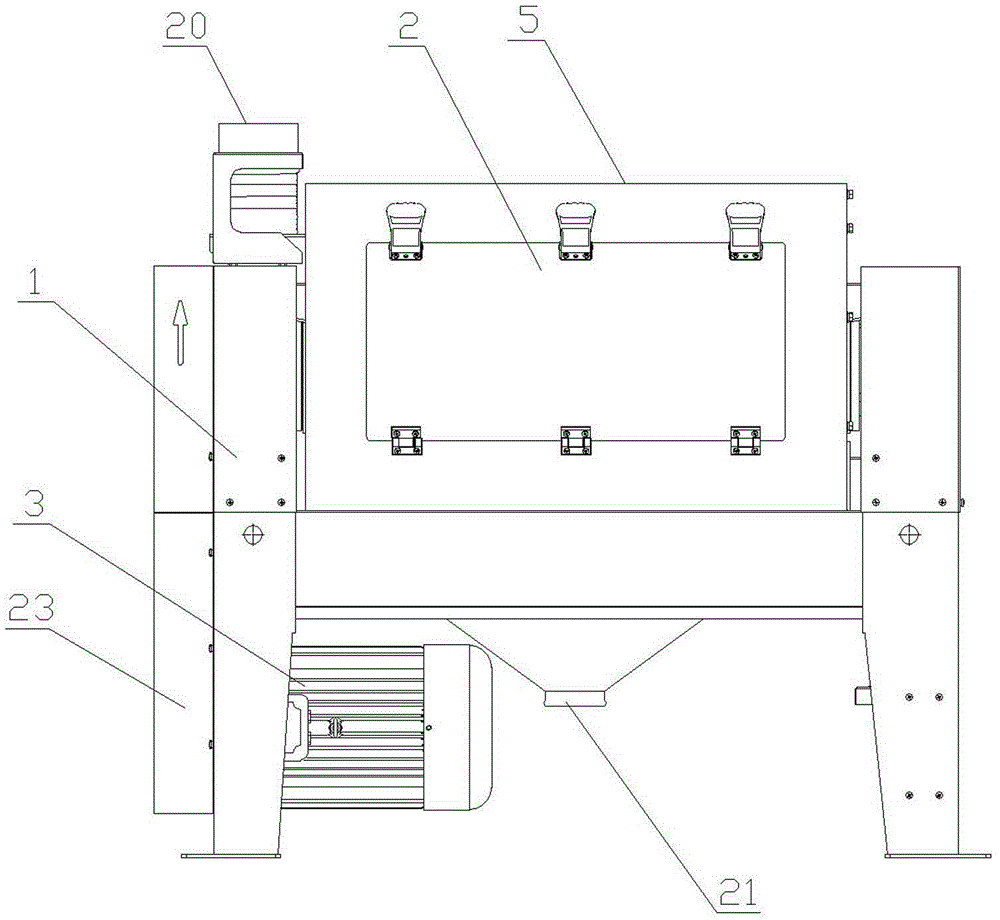

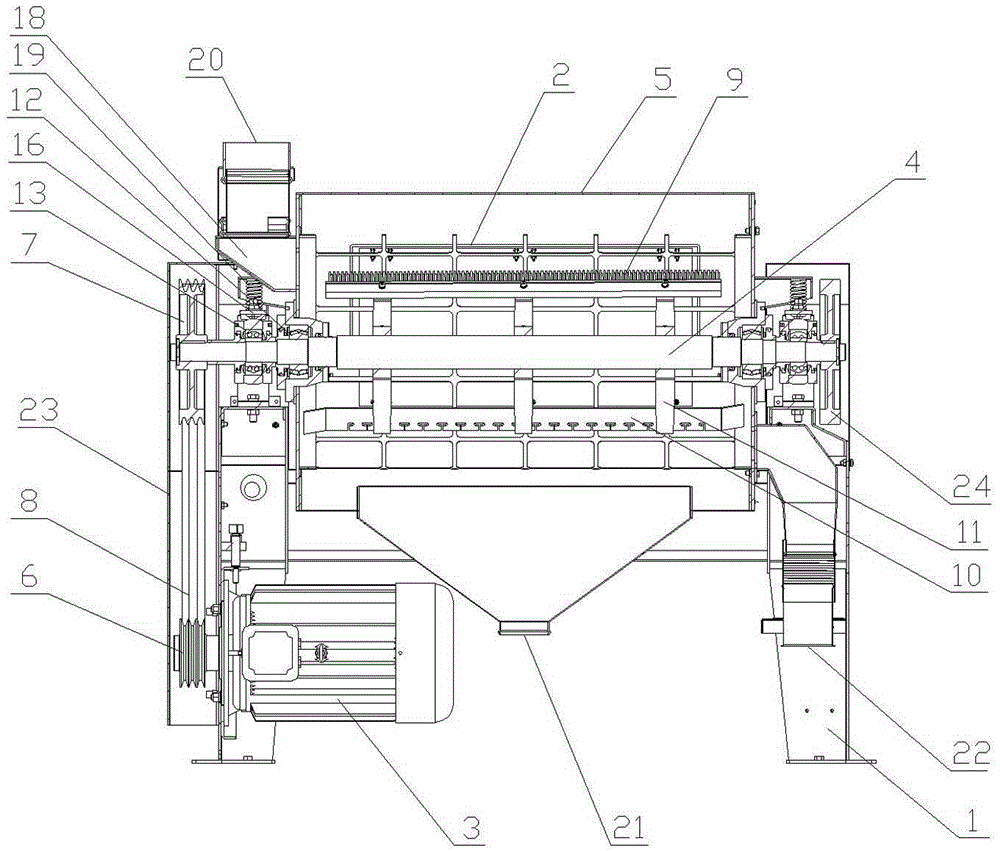

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0035] as attached Figure 1-6As shown, a novel dynamic separation screen includes a frame 1, a screen cylinder 2 arranged on the frame 1 and a motor 3 provided on the frame 1 to provide power for the screen cylinder 2, and the inner wall of the screen cylinder 2 is provided with There is a sieve 15 tensioned by a sieve pressing mechanism 14, and the sieve 15 selects a suitable sieve hole diameter according to the diameter of the material to be screened. Ring, and then the screen 15 is fastened by bolts and screws. The sieve cylinder 2 includes a sieve cylinder main shaft 4 connected to the frame 1 by a sieve cylinder support bearing 13 and a sieve cylinder housing 5 arranged on the sieve cylinder main shaft 4; the sieve cylinder main shaft 4 is an eccentric shaft, and the sieve cylinder main shaft The eccentric distance of 4 is 1.5mm, and the screen cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com