Phosphor-dispersed glass and method for producing same

A manufacturing method and phosphor technology, applied in chemical instruments and methods, luminescent materials, semiconductor devices, etc., can solve problems such as hindering LED work and resin degradation, and achieve the effects of inhibiting deactivation, high color rendering, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

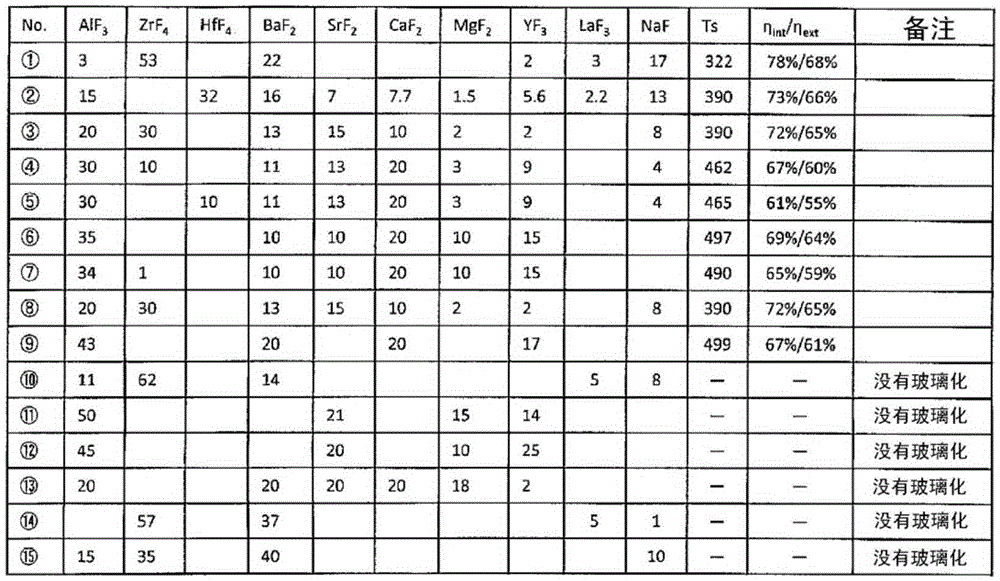

[0073] Using the fluorine compounds shown in Table 1 as starting materials, the glass raw materials prepared so as to reach the molar ratios of No. 1 to No. 9 in Table 1 were put into a glassy carbon crucible, and the In a 99% nitrogen atmosphere, melt at 980°C for 1 hour, and then quench the melt to obtain fluoride glass.

[0074] Next, the softening temperature (Ts) of the glass was measured. The softening temperature (Ts) was measured using a wide range viscometer (manufactured by Opt, Inc, WRVM-313). The softening temperature (Ts) of the glass is all 500 degrees C or less.

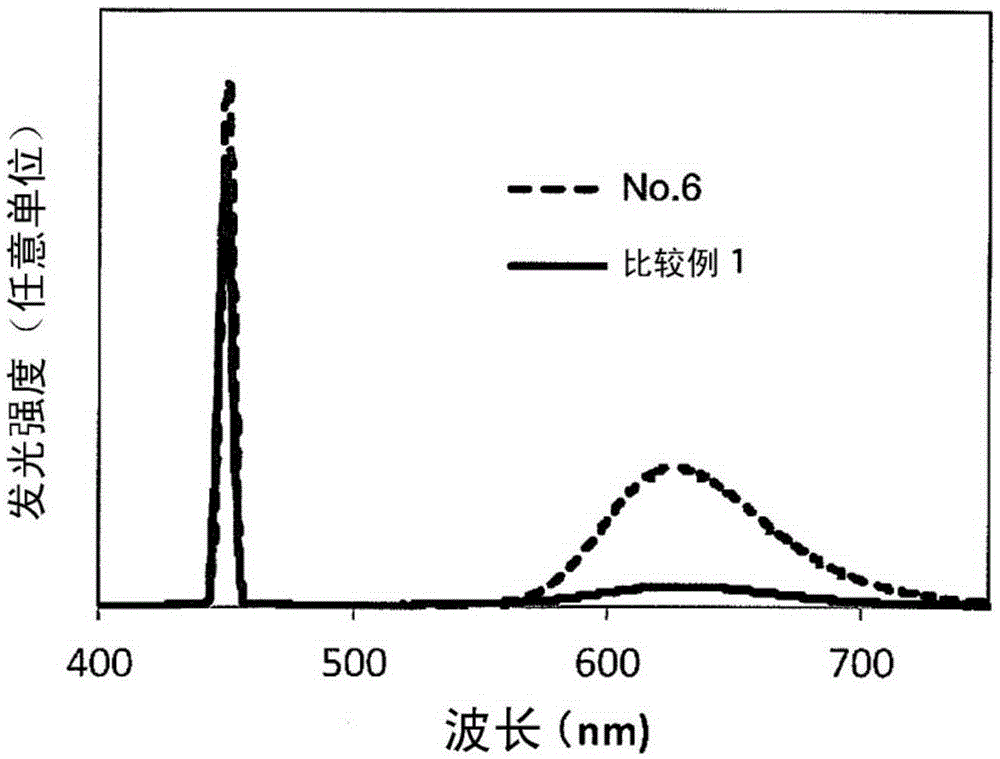

[0075] Next, the obtained glass was pulverized to a median particle size d50=10 μm to form a glass powder, and 5% by mass of a nitride phosphor (CaAlSiN 3 : Eu 2+ , Luminescence center wavelength 630nm) powder, fully mixed. After mixing, they were press-molded into pellets with a diameter of 12 mm and a thickness of 2 mm, and were heated for 1 minute at the softening temperature of each composition...

Embodiment 2

[0095] Samples were obtained in the same manner as in Example 1 except that the fluoride glass having the same composition as No. 6 in Table 1 was used and the phosphor was YAG-Ce.

[0096] The internal quantum efficiency of the YAG-Ce phosphor particles used in the study was measured before sealing the glass, and it was 83%. The internal quantum efficiency of the sample obtained in Example 2 was 74%, and it can be seen that the inactivation of the phosphor can be suppressed. It was confirmed that the fluoride glass used in the present invention can also be used for sealing oxide phosphors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com