Method and equipment for cleaning workpiece and method and equipment for cleaning tire loose die

A tire active mold and workpiece technology, which is applied in the field of workpiece cleaning and cleaning, can solve the problems that affect the appearance and quality of the product, the corner effect of the workpiece is not ideal, and the cleaning has no obvious effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

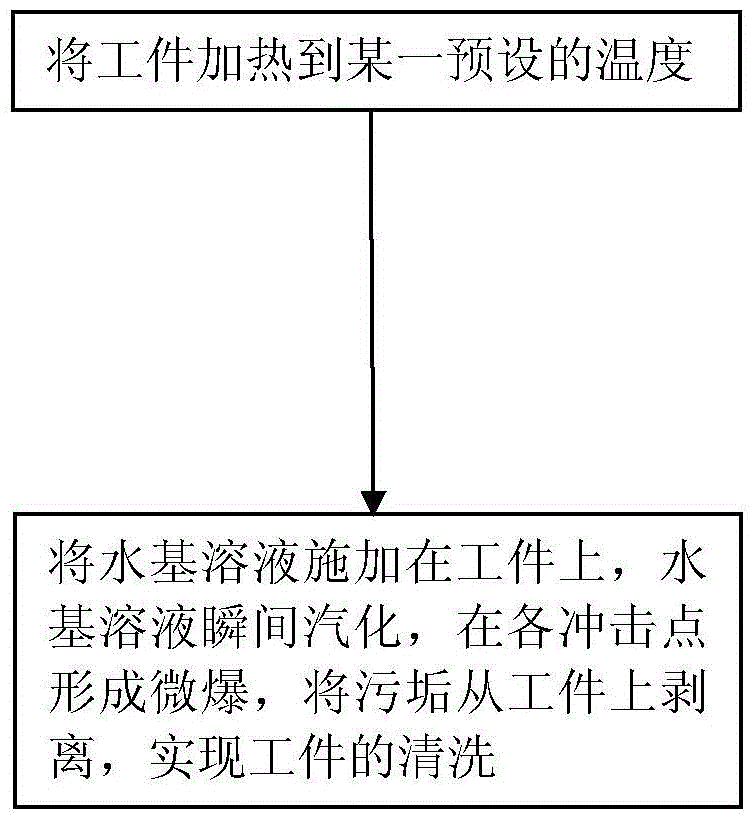

[0053] Such as figure 1 As shown, the present invention provides a method for cleaning a workpiece, the method including:

[0054] a) Heat the workpiece to a preset temperature;

[0055] b) The water-based solution is applied to the workpiece, and the water-based solution instantly vaporizes, forming a micro-explosion at each impact point, peeling off the dirt from the workpiece, and realizing the cleaning of the workpiece.

[0056] Specifically, in step a, the workpiece is heated to a certain preset temperature, the preset temperature is, for example, 100°C to 600°C, preferably, the preset temperature may be 350°C, and the preset temperature The specific selection depends on the material of the workpiece, the working condition of use and the premise of not affecting the deformation and accuracy of the workpiece, and there is no restriction here. Step a is to pre-heat the workpiece to make the workpiece meet the spraying requirements required by step b).

[0057] In the present inven...

Embodiment approach 2

[0065] Such as Figure 4 and Figure 5 As shown, the present invention also provides a device for cleaning a workpiece. The device includes a heating device 1 and a cleaning device 2. The heating device 1 heats the workpiece 3 to a predetermined temperature range; the cleaning device 2 heats the water-based The solution is applied to the workpiece 3, and the water-based solution instantly vaporizes, forming a micro-burst at each impact point, peeling off the dirt from the workpiece, and realizing the cleaning of the workpiece.

[0066] Specifically, the equipment for cleaning workpieces has an outer frame 9, which is generally rectangular parallelepiped, the heating device 1 is located at one end of the outer frame 9, the cleaning device 2 is located at the other end of the outer frame 9, the heating device 1 and the cleaning device 2 They are arranged oppositely along the diagonal of the outer frame 9.

[0067] Such as Image 6 As shown, the heating device 1 includes a heating fur...

Embodiment approach 3

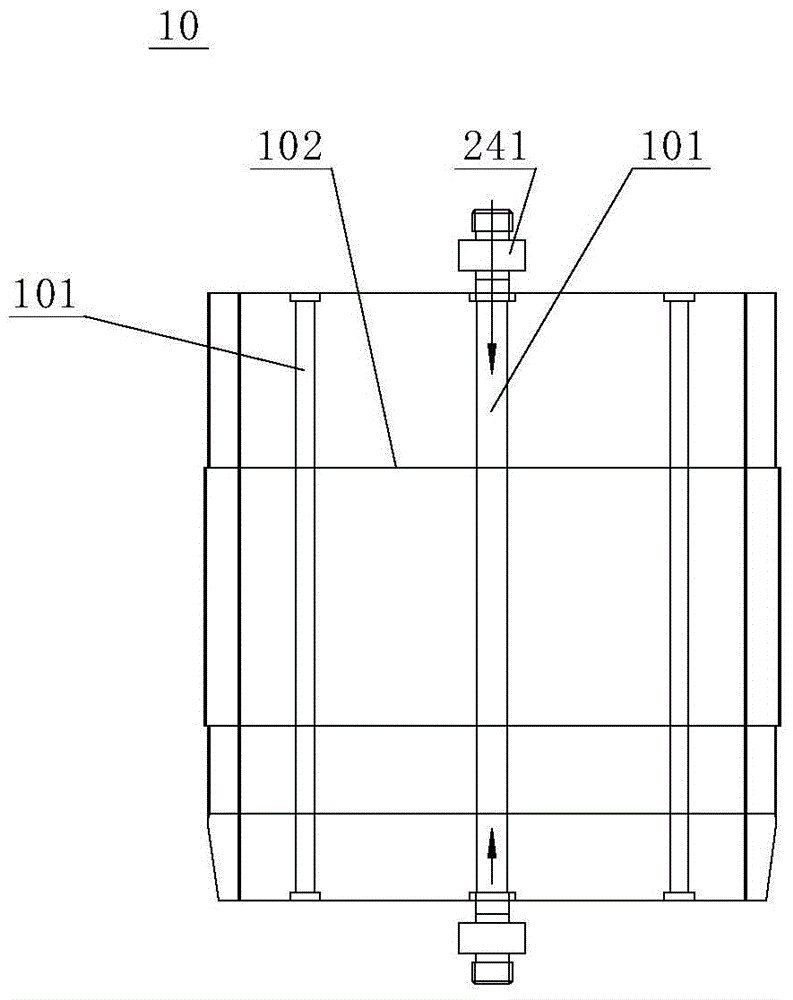

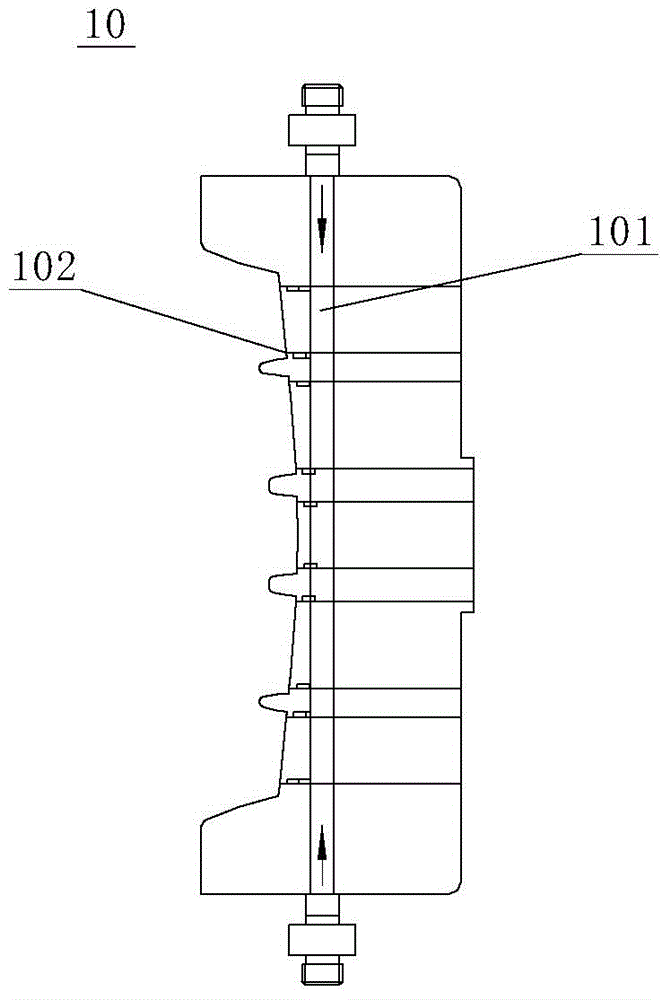

[0084] Such as Figure 1 to Figure 3 As shown, the present invention also provides a method for cleaning a non-porous tire active mold. A water-based organic solution is injected from the upper and lower holes of the non-porous tire active mold 10 into the inner channel 101 of the mold. After vaporization, it flows out through the mold gap 102. The method for cleaning the workpiece described in the first embodiment is used to clean the airless tire movable mold 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com