Colored paint production reaction kettle convenient for material supplement

A technology of reaction kettle and reaction kettle body, which is applied in the field of reaction kettles for color paint production, and can solve problems such as affecting production progress and troublesome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

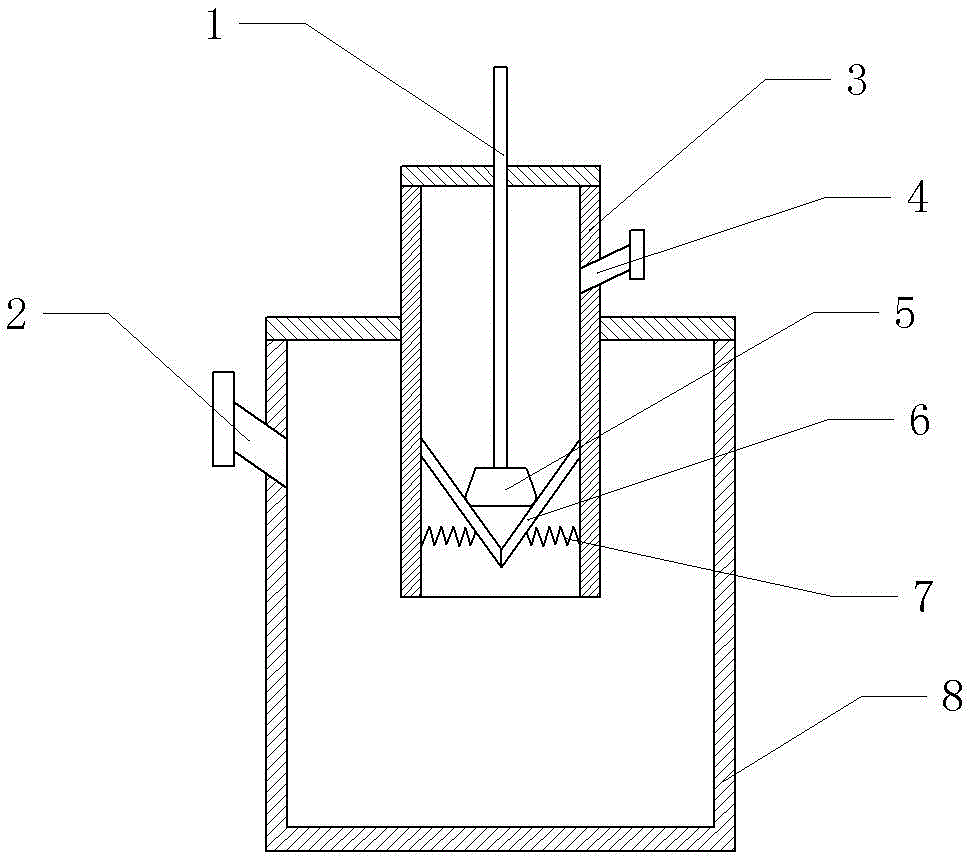

[0018] The reference signs in the accompanying drawings of the description include: strut 1 , feeding pipe 2 , feeding pipe 3 , feeding pipe 4 , brace 5 , sealing plate 6 , pressure spring 7 , and reactor body 8 .

[0019] Such as figure 1 As shown, the reaction kettle for color paint production that is convenient for replenishment includes a reactor body 8, and a feed pipe 2 is provided on the side wall of the reactor body 8 for adding raw materials. The end of the feed pipe 2 is provided with There is a sealing cover; the top of the reaction kettle body 8 is provided with a square feeding pipe 3, and the side wall of the square feeding pipe 3 includes the left side, the right side, the front side and the rear side, and the upper end of the feeding pipe 3 is provided with a first Tube cover; feeding tube 3 is provided with feeding tube 4 on the side wall above the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com