Matte tone transfer film and molded article using same

A transfer film, color tone technology, applied in synthetic resin layered products, processes and applications for producing decorative surface effects, can solve problems such as coating film depressions, achieve excellent mold release, inhibit thermal wrinkle or The effect of improving adhesion and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A biaxially stretched polyester film (manufactured by Mitsubishi Plastics Corporation: G440E50) with a thickness of 50 μm was used as a base film, and the following composition was applied on one surface using a microgravure method so that the film thickness after drying became 0.2 μm The coating solution for the release layer is dried to form a release layer. After that, it aged at 50 degreeC for 5 days, and produced the release film.

[0060] (Composition of Coating Liquid for Release Layer)

[0061]

[0062] Next, a coating solution for a hard coat layer having the following composition was applied on the release layer of the release film using a microgravure method so that the film thickness after drying became 4.0 μm, and dried to form a hard coat layer.

[0063] (Composition of Coating Liquid for Hard Coating)

[0064] ・Ultraviolet curable resin (manufactured by DIC Corporation: RC29-117, added with an ultraviolet polymerization initiator, solid content: 30%)...

Embodiment 2

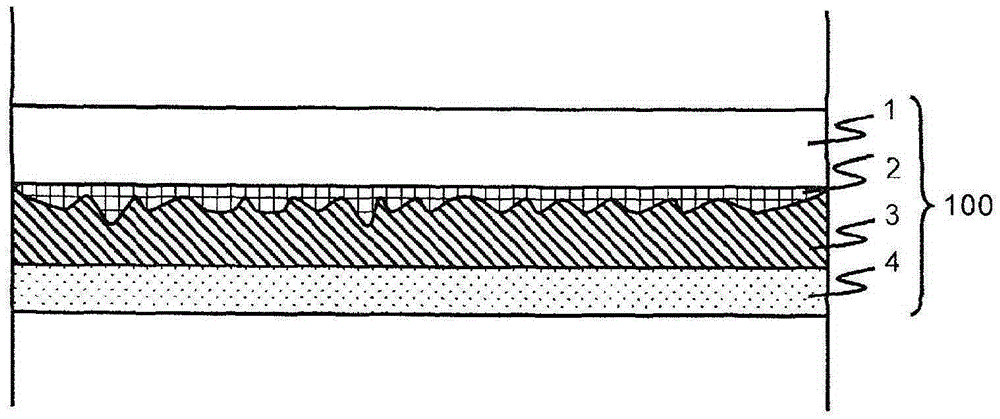

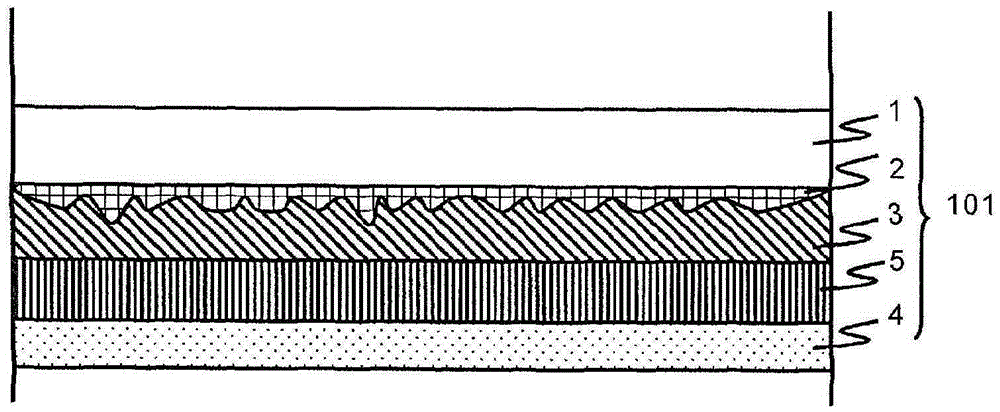

[0069] In the same manner as in Example 1, a release layer and a hard coat layer were sequentially laminated on one surface of the base film.

[0070] Next, an acrylic polyol / isocyanate-based coating solution (manufactured by Toyo Ink Co., Ltd.: V425Anchor) was applied as a coating solution for an undercoat layer on the above-mentioned hard coat layer using a gravure method so that the film thickness after drying became 2 μm. , forming an undercoat. Printing is performed thereon with a predetermined coating liquid for a decorative layer to form a decorative layer. Furthermore, an adhesive layer coating liquid (manufactured by Toyo Ink Co., Ltd.: K539HP adhesive varnish) was coated using the gravure method so that the film thickness after drying became 1 μm, to form an adhesive layer. Thus, the matte tone transfer film of Example 2 was produced.

[0071] Next, install the above-mentioned matte tone transfer film and the notebook computer housing made of polycarbonate / ABS allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com