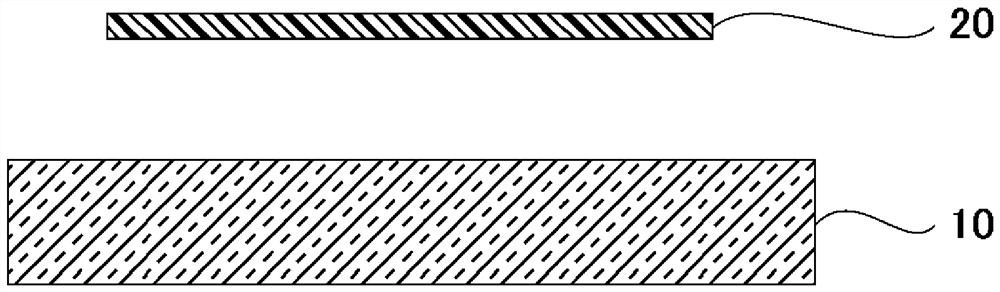

Manufacturing method of bonded structure and anisotropic conductive adhesive film

A connection structure, anisotropic technology, applied in the direction of conductive adhesive, film/sheet without carrier, connection, etc., can solve the problems of wiring hardening, difficult to obtain on-resistance, etc., and achieve the effect of excellent on-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055]

[0056] Hereinafter, examples of the present invention will be described. In this example, an anisotropic conductive film was produced, bonded structures were fabricated using it at various irradiation timings, and the conduction resistance and curing rate of the bonded structures were evaluated. In addition, this invention is not limited to these Examples.

[0057] Production of the bonded structure, measurement of conduction resistance, and measurement and evaluation of the curing rate were performed as follows.

[0058] [Creation of connection structure]

[0059] As evaluation base materials, TI / Al plated glass substrates (metal wiring, t=0.7mm) and ICs (1.8mm×20mm, t=0.5mm, Au-plated bumps: 30μm×85μm, h=15μm) were used. The light irradiation condition is set to 200mW / cm 2 -3 seconds. In addition, the thermocompression bonding conditions were set at 120°C - 60 MPa - 5 seconds.

[0060] [Measurement of conduction resistance]

[0061] The conduction resistance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com