Color temperature adjustable LED integrated light source

A light source and color temperature technology, applied in the field of lighting, can solve the problems that the entire light source board cannot work, cannot be repaired independently, and cannot achieve color temperature, etc., to achieve the effect of ensuring long-term reliability, reducing space occupation, and improving scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

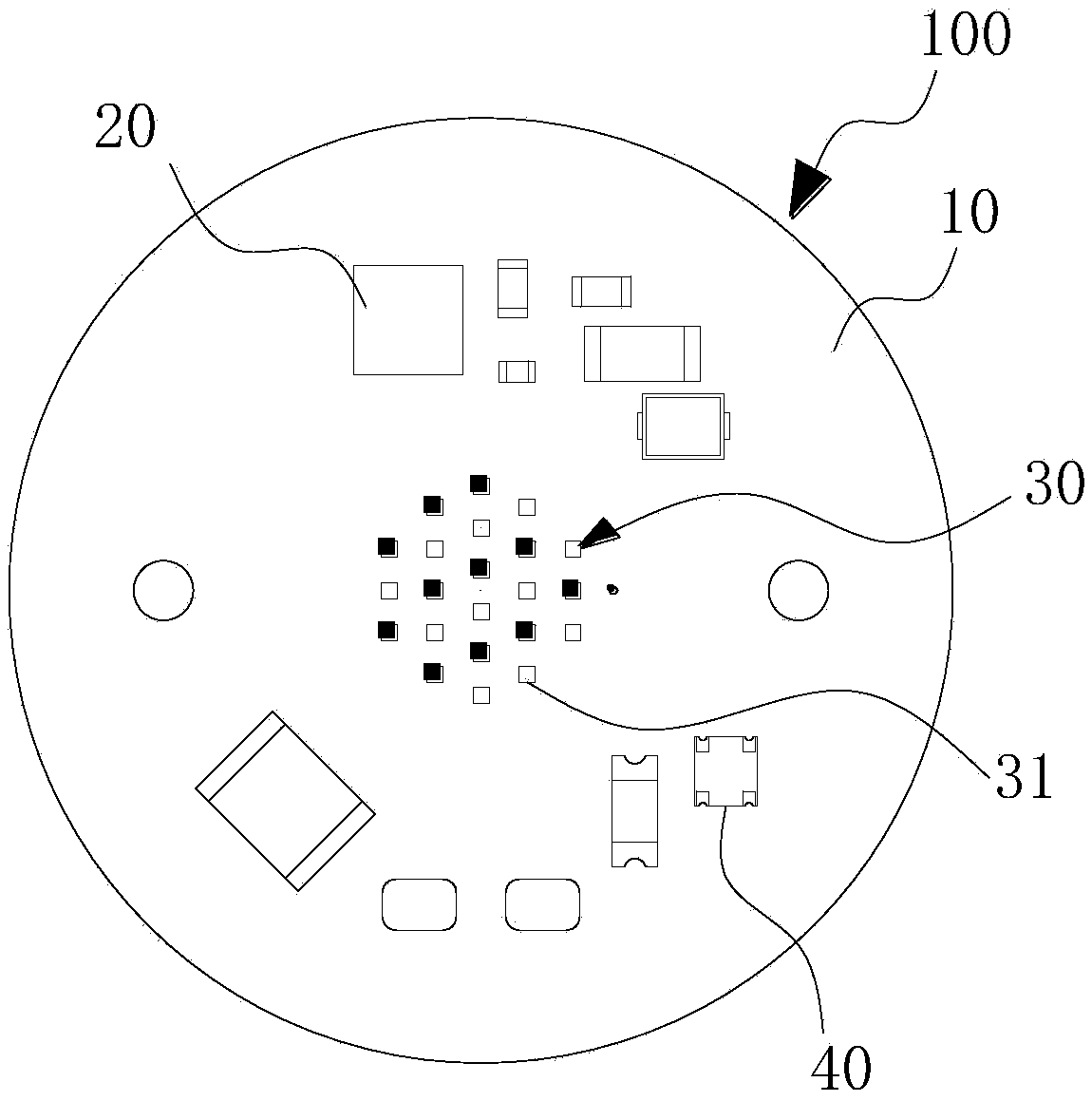

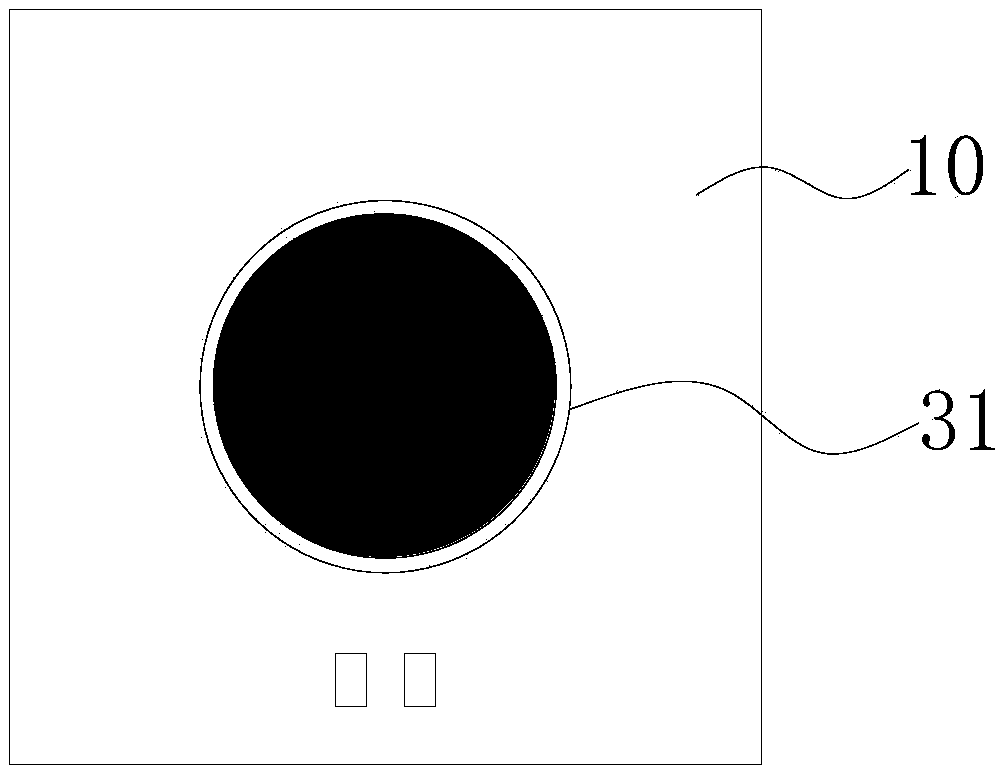

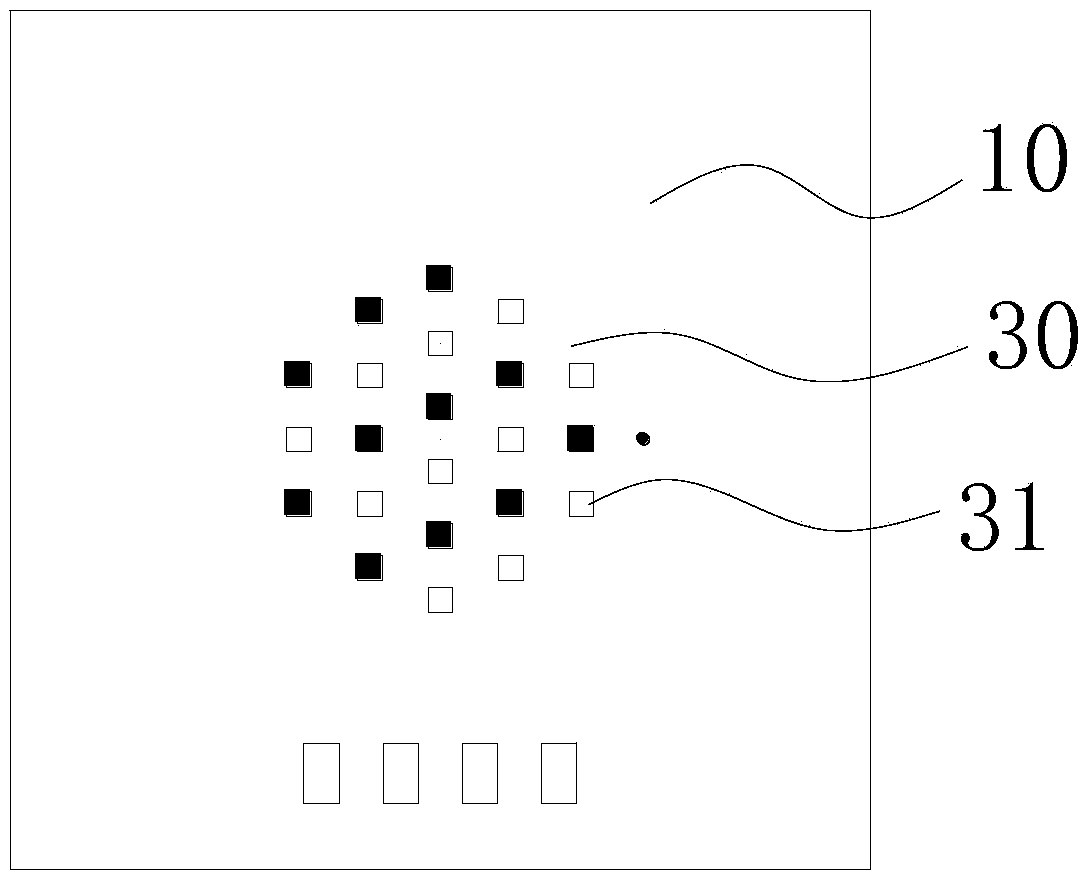

Embodiment 1

[0034] Embodiment 1: Two independent lines are arranged on an aluminum substrate, and white LEDs with two color temperatures of 5000K cool white LEDs and 2600K warm white LEDs are respectively packaged to form a lamp group. Lamp groups with two color temperatures are placed in a light-emitting surface with a diameter of 10-30 mm, and the white LEDs are arranged closely at intervals. When working, the drive IC adjusts the current to the two lines through the drive circuit. When the current of the cool white lamp group is equal to the current of the warm white lamp group, the entire light source presents a positive white effect of about 3500K; when the cool white lamp group When the current of the group is lower than that of the warm white lamp group, the entire light source is warmer white; when the current of the cool white lamp group is greater than the current of the warm white lamp group, the entire light source is cooler white. In this embodiment, the color presented by th...

Embodiment 2

[0035] Embodiment 2: A light engine solution for a small light-emitting surface, using three kinds of LEDs with different white color temperatures to form three groups of lamps, each group of lamps is powered by a line independently, and the three lines are driven by a driver IC. The on-off time or the input voltage of the three lines and the corresponding port of the driver IC are used to control the current of the three lines respectively, so as to achieve the functions of adjusting color temperature, brightness, and display. In this embodiment, the rectifier bridge, TVS, fuse and other protection devices can also be integrated on the substrate, and all the devices can be mounted at one time, saving the production time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com