Hard-sealing fast ball valve

A hard-sealed and fast technology, used in shaft seals, valve details, valve devices, etc., can solve the problems of short service life of ordinary ball valves, limited diameter application, large flow resistance of globe valves, etc., and achieve large shear and extrusion. Stress, load uniformity, ensure the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

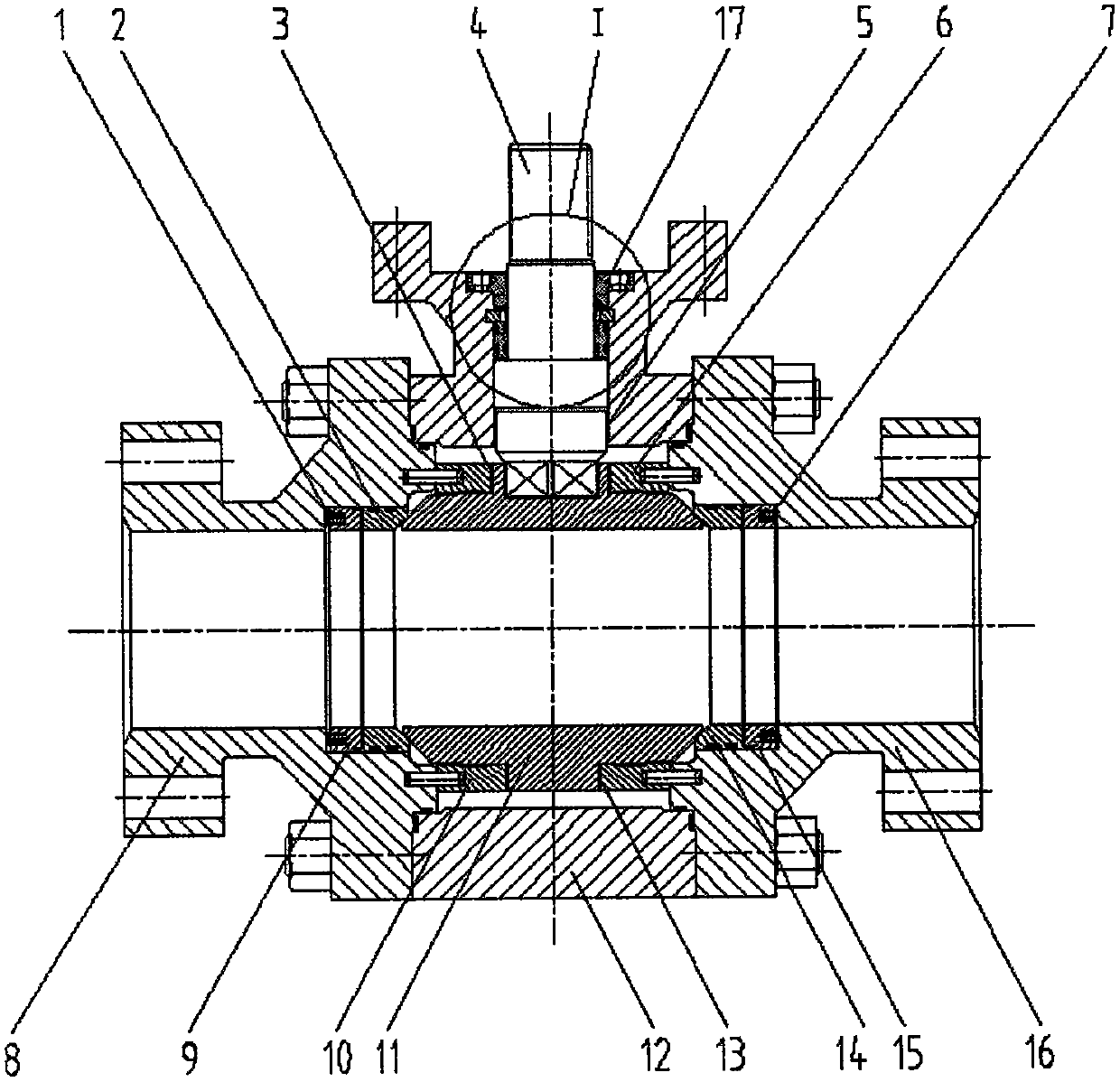

[0026] The following takes the hard-sealed fast ball valve in a temporary hypersonic wind tunnel as an example, and describes it in more detail in conjunction with the attached drawings:

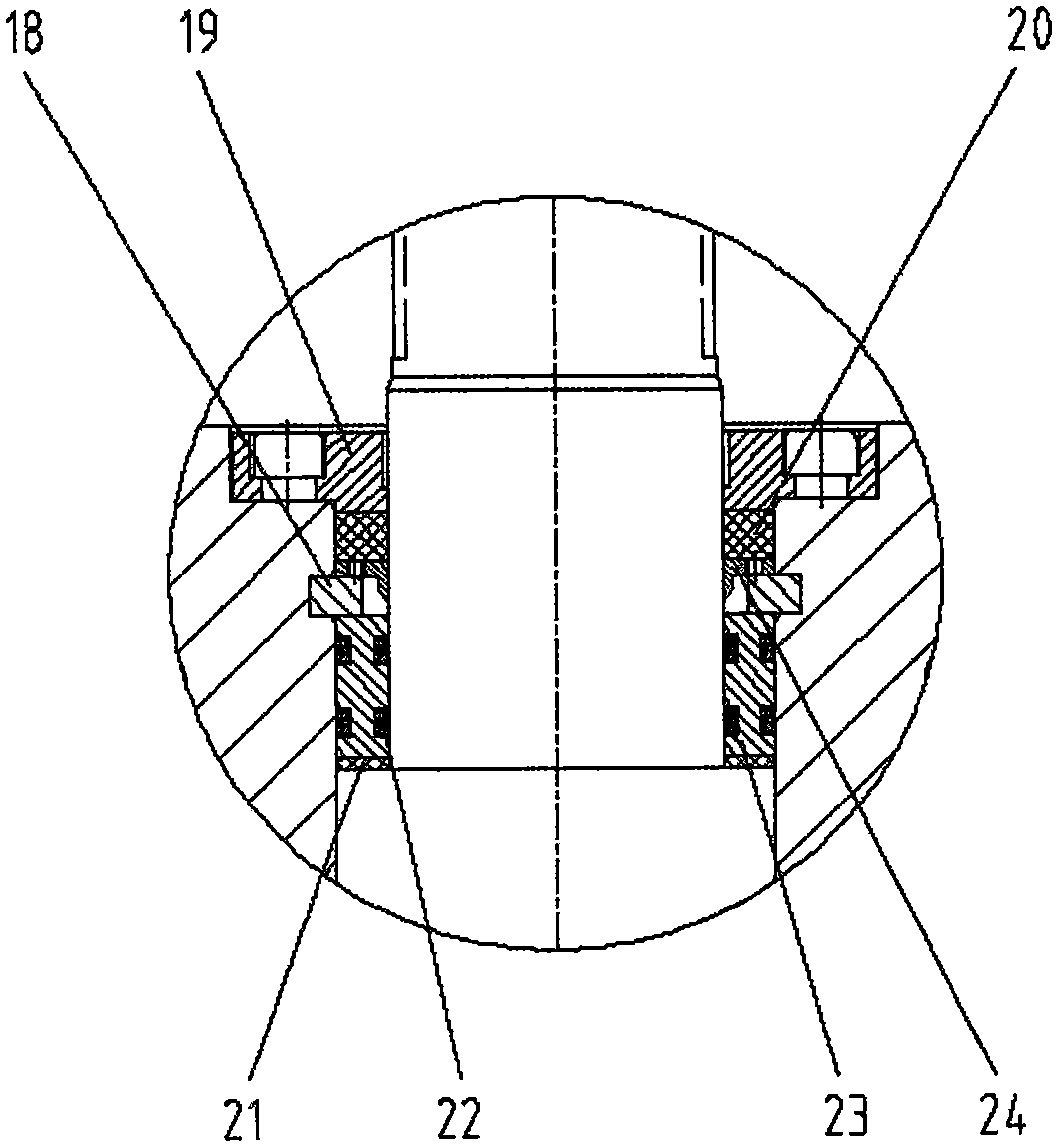

[0027] figure 1 It is a sectional view of the overall structure of the hard-sealed quick ball valve of the present invention, figure 2 for figure 1 Partial enlarged view of upper sealing structure at middle I.

[0028] Such as figure 1 As shown, a hard-sealed fast ball valve provided by the embodiment of the present invention includes a valve body 12, a left valve cover 8, a right valve cover 16, a ball core 11, a left valve seat 2, a right valve seat 14, a valve stem 4, an upper Support plate 6, lower support plate 10, left load spring 1, right load spring 7, left pressure ring 9, right pressure ring 15, upper sliding bearing 3, lower sliding bearing 13, valve stem sliding bearing 5, upper sealing structure 17. The left valve cover 8 and the right valve cover 16 are fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com