Emergency-door and end-door push rod lock for rail transit platform

A technology for rail transit and emergency doors, applied in the field of hardware, can solve the problems of unlocking without multi-level protection, lock without self-protection, complex or simple internal structure, etc., so as to reduce the unlocking force and the non-interference of unlocking, and improve the stability and reliability. and response speed, increasing effectiveness and rapidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

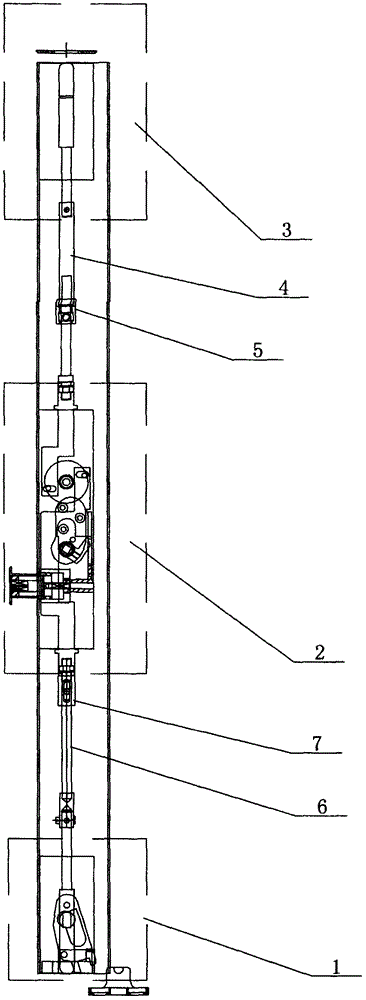

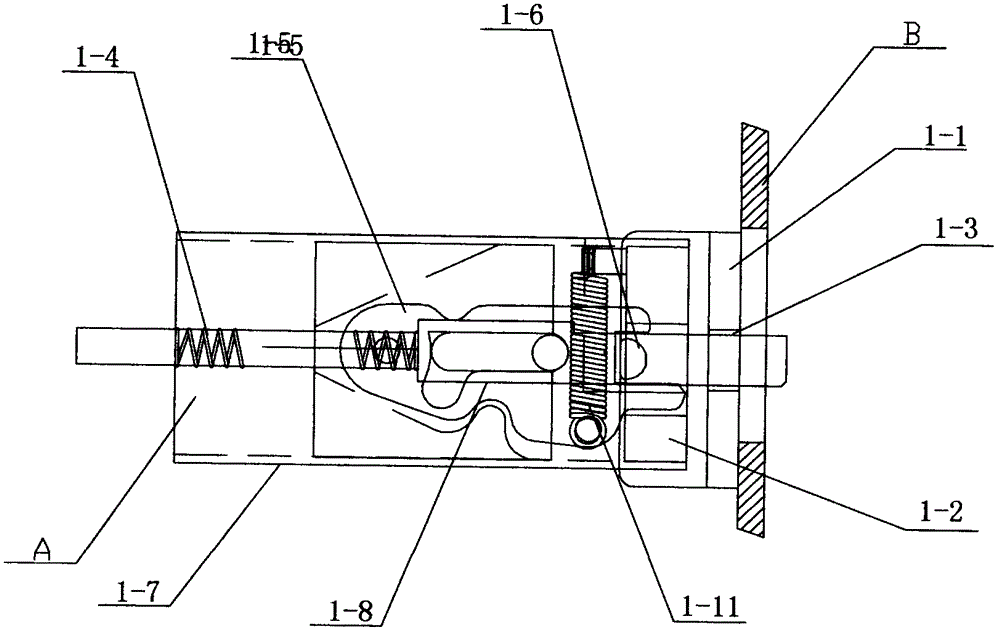

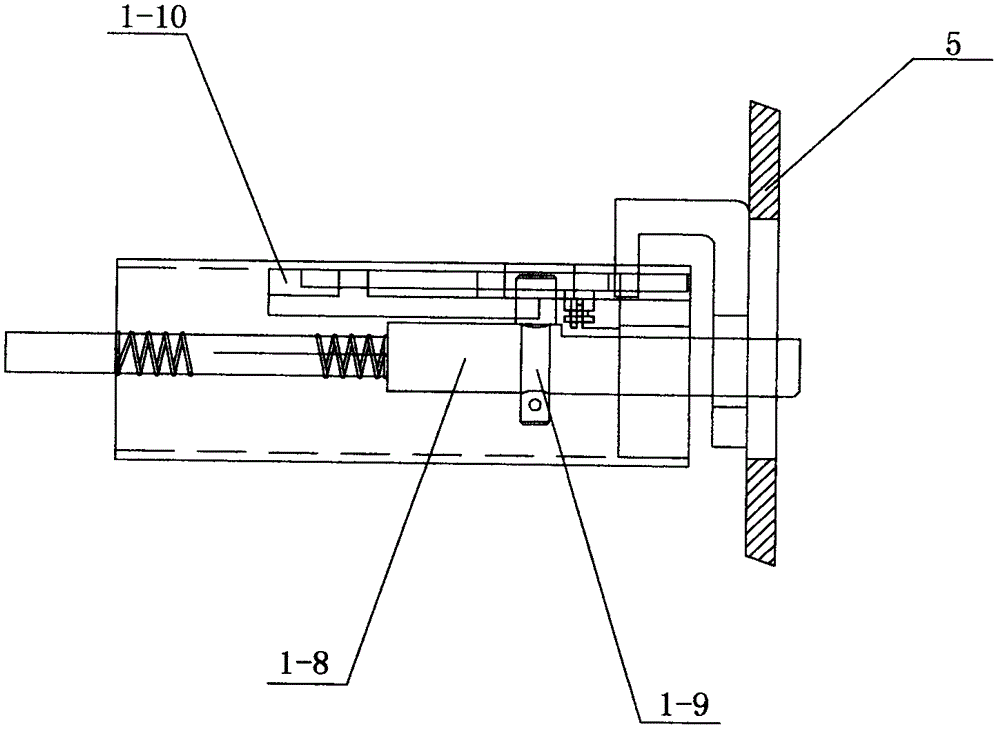

[0022] see Figure 1-Figure 5 , this specific embodiment adopts the following technical scheme: it includes an unlocking unit 1, a central control locking unit 2, and a locking bolt unit 3, and the locking bolt unit 3 and the central controlling locking unit 2 are connected by a No. 1 connecting rod 4. The No. 1 connecting rod 4 is provided with a large-scale length-adjusting sudden death fastening connector 5, and the central control lock unit 2 and the unlocking unit 1 are connected through the No. 2 connecting rod 6, and the No. 2 connecting rod 6 is provided with There is a fine-tuning length fastening connector 7; the unlocking unit 1 includes an unlocking hole seat 1-1, a lower lock seat 1-2, a lock hole 1-3, a first return spring 1-4, and a switch dial 1- 5. Attachment pin 1-6, fixed pipe 1-7, lock bolt 1-8, limit pin 1-9, switch mounting seat 1-10, second return spring 1-11, unlocking hole seat 1-1 Installed on the footboard B, and the unlocking hole seat 1-1 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com