PVC environment-friendly nanometer heat stabilizer and preparation method thereof

A heat stabilizer and nano technology, applied in the field of PVC environmental protection nano heat stabilizer and its preparation, can solve the problems of precipitation, affecting the processing process and product quality, etc., and achieve the effect of large adsorption capacity, good stabilization effect and good mutual solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

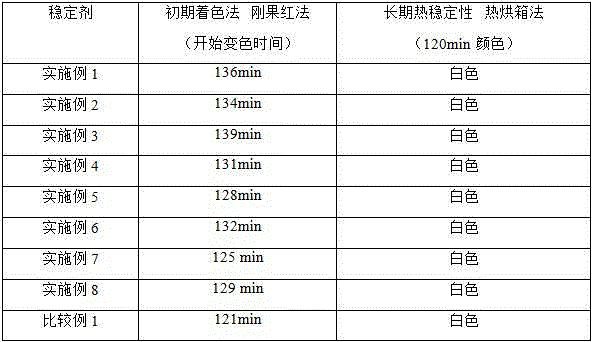

Examples

Embodiment 1

[0022] Weigh the following components:

[0024] Zinc stearate 280g;

[0025] Hydrotalcite 100g;

[0026] Hollow titanium dioxide nanosphere particle size 30nm80g (8%);

[0027] Paraffin 80g;

[0028] Dipentaerythritol ester 50g;

[0029] Dibenzoylmethane 90g.

[0030] First add calcium stearate, zinc stearate and hydrotalcite into the reaction kettle and mix thoroughly, take the mixed material, add it to the kneader and stir, add the surface modifier, knead at 95°C for 30min, and then add it to the kneader Lubricant, hollow titanium dioxide nano-microspheres and auxiliary heat stabilizer are kneaded and stirred at 95°C for 40 minutes, discharged into tablets, sieved, and packaged to obtain the final product.

[0031] Implementation 2 / 3 / 4 / 5

[0032] Others are the same as in Example 1, and the particle diameters of the hollow titanium dioxide nanospheres are 20nm / 25nm / 40nm / 50nm respectively.

Embodiment 6

[0034] Weigh the following components:

[0035] Calcium stearate 350g;

[0036] Zinc stearate 300g;

[0037] Hydrotalcite 150g;

[0038] Hollow titanium dioxide nanosphere particle size 30nm50g;

[0039] Polyethylene wax 60g;

[0040] Triphenyl phosphite 30g;

[0041] Epoxidized soybean oil 60g.

[0042] First add calcium stearate, zinc stearate and hydrotalcite into the reaction kettle and mix thoroughly, take the mixed material, add it to the kneader and stir, add the surface modifier, knead at 103°C for 30min, and then add it to the kneader Lubricant, hollow titanium dioxide nano-microspheres and auxiliary heat stabilizer are kneaded and stirred at 103°C for 40 minutes, discharged into tablets, sieved, and packaged to obtain the final product.

Embodiment 7

[0044] Weigh the following components:

[0045] Calcium stearate 200g;

[0046] Zinc stearate 260g;

[0047] Hydrotalcite 100g;

[0048] Hollow titanium dioxide nanosphere particle size 20nm100g (10%);

[0049] Paraffin 120g;

[0050] Triphenyl phosphite 70g;

[0051] Dibenzoylmethane 150g,

[0052] First add calcium stearate, zinc stearate and hydrotalcite into the reaction kettle and mix thoroughly, take the mixed material, add it to the kneader and stir, add the surface modifier, knead at 98°C for 30min, and then add it to the kneader Lubricant, hollow titanium dioxide nano-microspheres and auxiliary heat stabilizer are kneaded and stirred at 98°C for 40 minutes, discharged into tablets, sieved, and packaged to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com