Environment-friendly mulching film easy for recycling and preparation method thereof

An easy-to-recycle, mulch technology, applied in the fields of botany equipment and methods, plant protection, plant protection cover, etc., can solve the problems of incomplete mulch shape, low physical and mechanical performance indicators, difficult to recycle, residual film pollution, etc., reaching a wide range of regions. , the protection of cultivated land and the environment, the effect of high residual strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

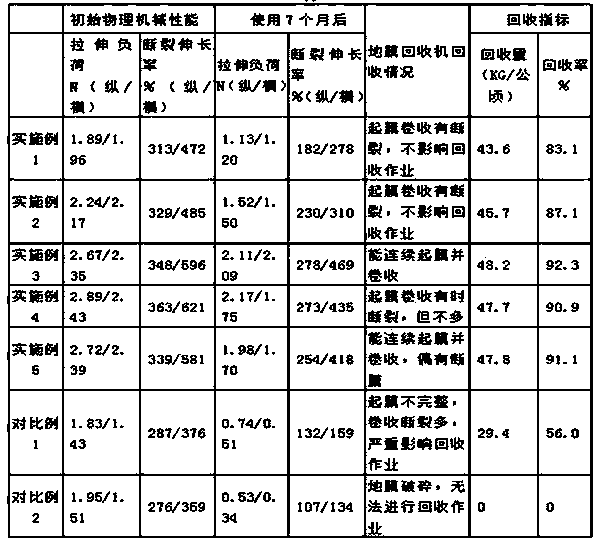

Examples

Embodiment 1

[0033] Weigh by weight: 10 parts of high pressure low density polyethylene, 50 parts of linear low density polyethylene resin, 25 parts of high pigment carbon black, 3.5 parts of polyethylene wax, 0.5 parts of coupling agent, 6 parts of polymerized hindered amine light stabilizer 2 parts, 2 parts of antioxidant, 3 parts of acid scavenger; Knead the above composition in an internal mixer at 130°C for 25 minutes, and then use a granulator to melt, plasticize and granulate to obtain the special anti-aging masterbatch A for mulch film.

[0034] Weigh by weight: 20 parts of high-pressure low-density polyethylene, 65 parts of linear low-density polyethylene resin, 8 parts of polymerized hindered amine light stabilizer, 2.5 parts of antioxidant, 4.5 parts of acid scavenger; Knead in an internal mixer at 130°C for 25 minutes, and then use a granulator to melt, plasticize and granulate to obtain the anti-aging masterbatch B for mulch film.

[0035] Weigh by weight: 80 parts of linear l...

Embodiment 2

[0039] The special anti-aging masterbatch A for mulching film and the special anti-aging masterbatch B for mulching film and the preparation method are the same as in Example 1, and are different from Example 1 as follows:

[0040] Weigh by weight: 70 parts of linear low-density polyethylene resin, 15 parts of metallocene polyethylene resin, 8 parts of high-density polyethylene, 7 parts of aging-resistant masterbatch for plastic film; fully mix the above compositions in a high-speed kneader Finally, it will be used as the A layer material.

[0041]Weigh by weight: 80 parts of linear low-density polyethylene resin, 10 parts of metallocene polyethylene resin, 8 parts of high-density polyethylene, 7 parts of anti-aging masterbatch for plastic film; fully mix the above compositions in a high-speed kneader Finally, it will be used as the B layer material.

[0042] The materials for layer A and layer B are blown into a mulch film with a thickness of 0.008 mm and a width of 900 mm w...

Embodiment 3

[0044] The special anti-aging masterbatch A for mulching film and the special anti-aging masterbatch B for mulching film and the preparation method are the same as in Example 1, and are different from Example 1 as follows:

[0045] Weigh by weight: 60 parts of linear low-density polyethylene resin, 20 parts of metallocene polyethylene resin, 5 parts of high-density polyethylene, 10 parts of anti-aging masterbatch A for plastic film; fully mix the above compositions in a high-speed kneader Finally, it will be used as the A layer material.

[0046] Weigh by weight: 65 parts of linear low-density polyethylene resin, 20 parts of metallocene polyethylene resin, 5 parts of high-density polyethylene, 10 parts of anti-aging masterbatch B for plastic film; fully mix the above compositions in a high-speed kneader Finally, it will be used as the B layer material.

[0047] The materials for layer A and layer B are blown into a mulch film with a thickness of 0.008 mm and a width of 900 mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com